Hydrophobic fiber felt reinforced titanium-silicon composite airgel and preparation method thereof

A composite aerogel and composite gel technology are applied in the field of hydrophobic fiber felt reinforced titanium-silicon composite aerogel and its preparation. The effect of obvious effect, low production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

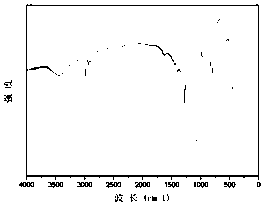

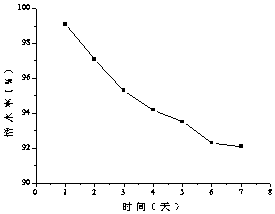

Image

Examples

Embodiment 1

[0034] Mix tetraethyl orthosilicate, absolute ethanol, deionized water, and 0.5mol / L hydrochloric acid uniformly in a volume ratio of 1:3.5:0.32:0.015. The mixing steps are:

[0035] (1) Mix tetraethyl orthosilicate with 2 / 3 of the volume of absolute ethanol, and stir to obtain solution A;

[0036] (2) Mix the remaining absolute ethanol with deionized water and HCl, and stir to obtain solution B;

[0037] (3) Slowly add solution B into solution A.

[0038] React at 50°C for 1h, under stirring, press SiO 2 :TiO 2 (Mass ratio) = 1:0.05 Add rutile titanium dioxide to SiO 2 In the sol, add 1mol / LNH 3 ·H 2 O to adjust the pH value of the solution to 6 and keep stirring to obtain TiO 2 -SiO 2 Composite sol;

[0039] TiO 2 -SiO 2 Pour the composite sol into the mold of the basalt fiber felt prefabricated part, wait for the sol to soak into the basalt fiber felt, pour out the excess sol, and leave the sol composite material at 50°C for 1 hour to form a gel composite material...

Embodiment 2

[0042] Tetraethyl orthosilicate, absolute ethanol, deionized water, and 0.8mol / L hydrochloric acid were uniformly mixed in a volume ratio of 1:4:0.32:0.015, and the mixing steps were the same as in Example 1.

[0043]React at 55°C for 1.2h, under stirring, press SiO 2 :TiO 2 (Mass ratio) = 1:0.07 Add anatase titanium dioxide to SiO 2 Sol, add 1.3mol / LNH 3 ·H 2 O to adjust the pH value of the solution to 6.3 and keep stirring to obtain TiO 2 -SiO 2 Composite sol;

[0044] TiO 2 -SiO 2 Pour the composite sol into the mold of the glass fiber mat prefabricated part, wait for the sol to soak into the glass fiber mat, pour out the excess sol, and leave the sol composite material at 60°C for 1.5h to form a gel composite material; the obtained gel The composite was subjected to solvent replacement with absolute ethanol solution at 60 °C for 2.5 days, and the surface modification of the gel composite was performed with trimethylchlorosilane for 2.5 days to obtain a hydrophobic ...

Embodiment 3

[0047] Tetraethyl orthosilicate, absolute ethanol, deionized water, and 1mol / L nitric acid were uniformly mixed in a volume ratio of 1:4.5:0.32:0.015, and the mixing steps were the same as in Example 1.

[0048] React at 65°C for 1.5h, under stirring, press SiO 2 :TiO 2 (Mass ratio) = 1:0.1 Add rutile titanium dioxide to SiO 2 Sol, add 1.6mol / LNH 3 ·H 2 O adjusted the pH value of the solution to 6.6, and kept stirring to obtain TiO 2 -SiO 2 Composite sol;

[0049] TiO 2 -SiO 2 Pour the composite sol into the mold of the mullite fiber felt prefab, wait for the sol to soak through the mullite fiber felt, pour out the excess sol, and leave the sol composite material at 65°C for 2.5h to form a gel composite material; The obtained gel composite was subjected to solvent replacement with absolute ethanol solution at 70 °C for 3 days, and the surface of the gel composite was modified with trimethylchlorosilane for 3 days to obtain a hydrophobic surface, and then used without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com