A kind of online dry production system and method of glass wool vacuum insulation board core material

A vacuum insulation panel and production system technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as inability to realize online continuous operation, discontinuous dry process operation, and difficulty in actual production and application, so as to reduce investment costs and technology The effect of difficulty, internal microstructure balance and stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

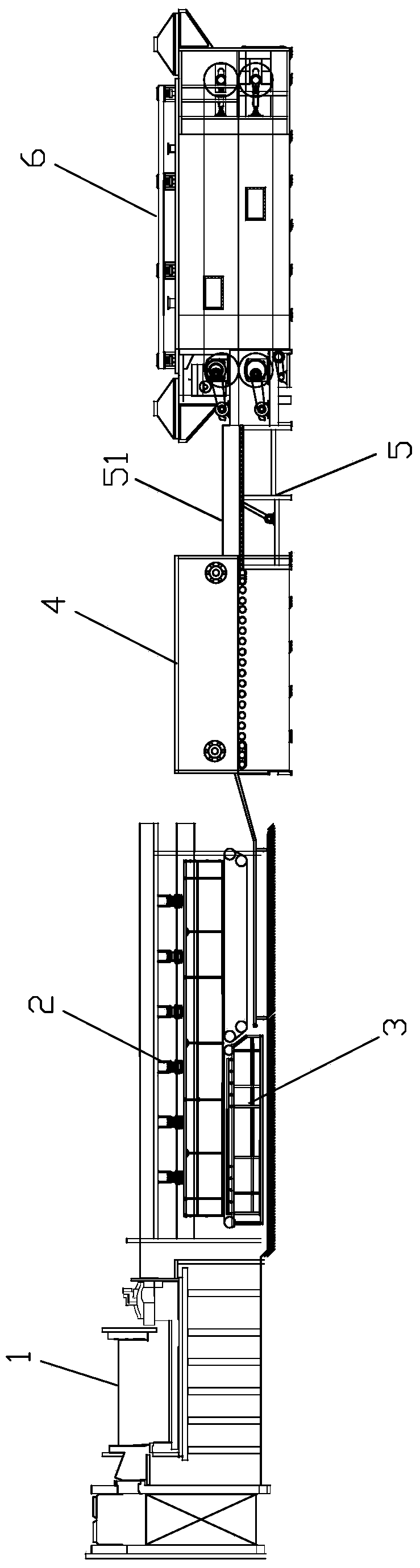

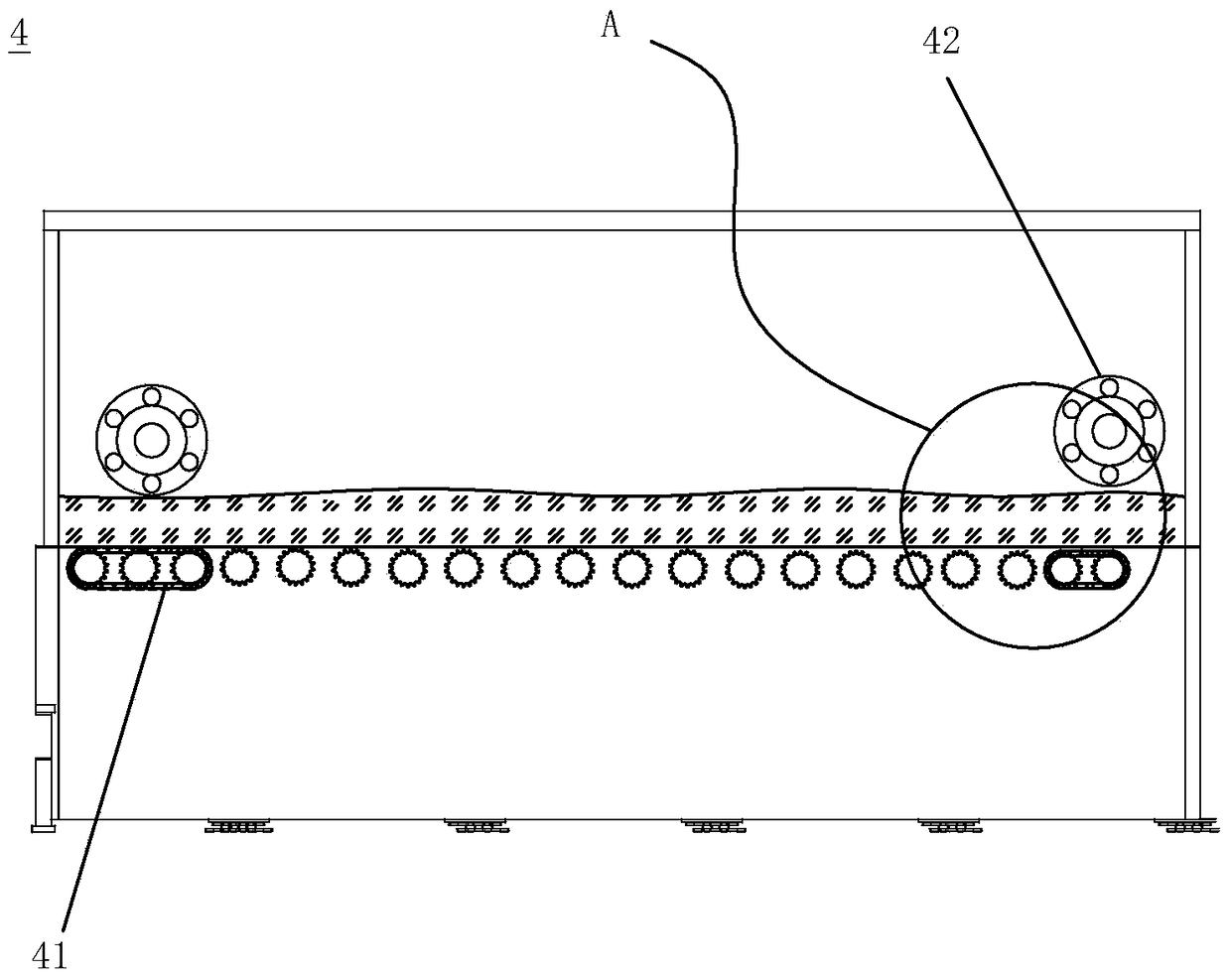

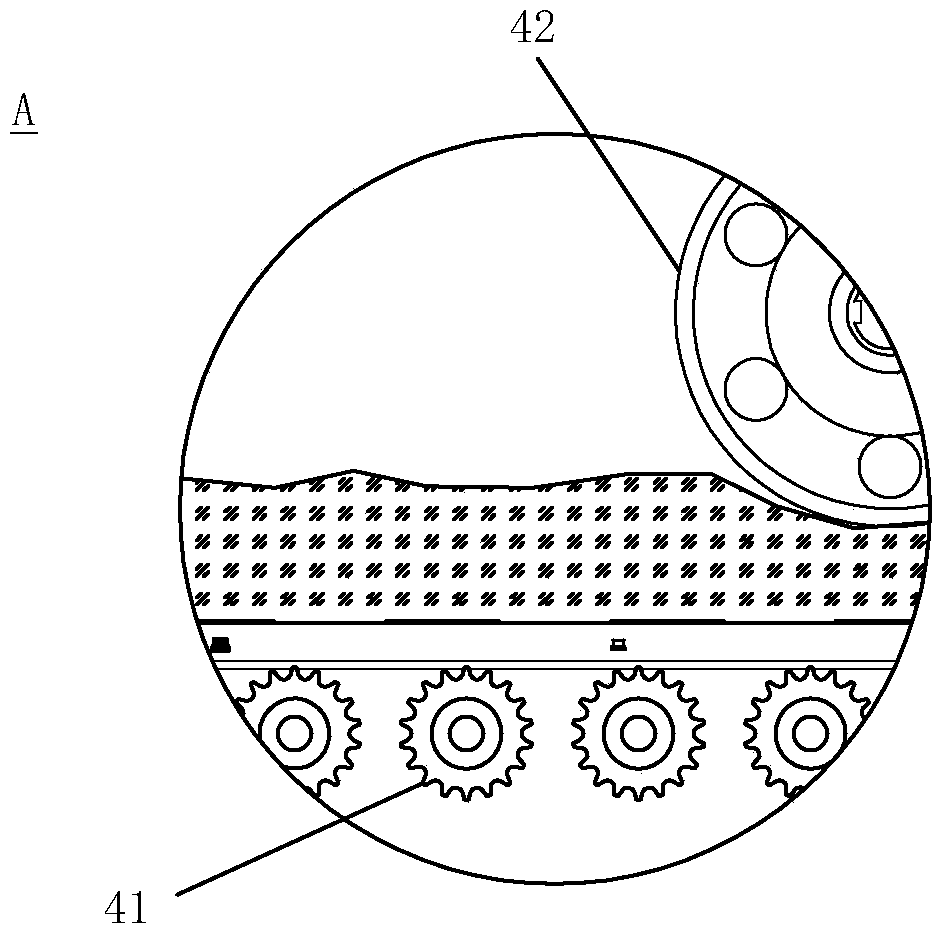

[0024] refer to figure 1 , an online dry process production system for glass wool vacuum insulation board core material in this embodiment, including a melting furnace 1, a centrifuge 2, a cotton collector 3, a heating furnace 4, a conveying device 5 and a setting device 6. The melting furnace 1 is used to melt raw materials to form molten glass; the centrifuge 2 is used to spin the molten glass into glass fibers; the cotton collector 3 is arranged under the centrifuge to collect glass fibers to form a glass wool layer; the heating furnace 4 is used to Heating the glass wool layer to above the brittle transition temperature, the sizing device 6 is used for the glass wool layer heated by hot pressing to form a glass wool blanket; the transfer device 5 is connected between the heating furnace 4 and the sizing device 6, and can be for example a conveyor belt, Known transmission equipment such as a transmission chain can be provided with a movable heat preservation cover to mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com