Metal material electrochemical test in situ diffraction and imaging experiment method

A material electrochemical and experimental method technology, applied in the field of metal material electrochemical test in situ diffraction and imaging experiments, can solve the problems of combination and inability to directly observe the real-time transformation of dynamic corrosion substances of metal materials, and achieve simple steps and high space and the effect of time resolution advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

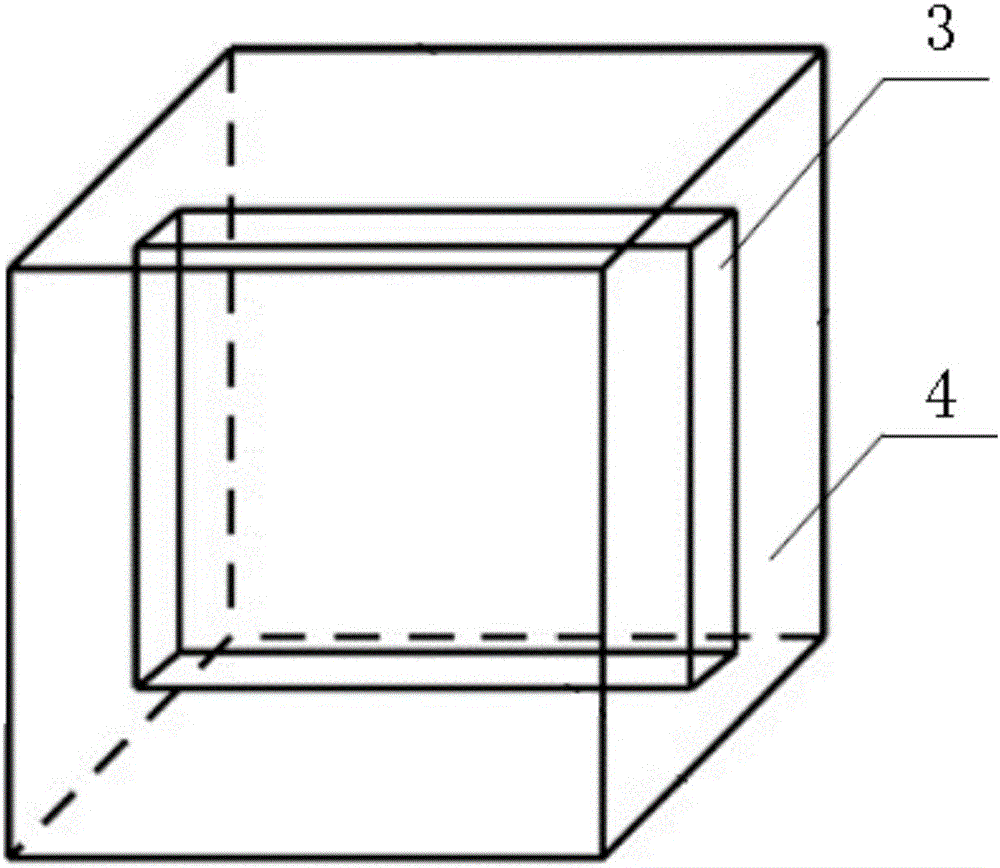

Image

Examples

Embodiment 1

[0029] This embodiment discloses an in-situ imaging experimental method for electrochemical testing of metal materials, taking aluminum alloy as an example, including the following steps:

[0030] (1) Ultra-thin sample preparation: the aluminum alloy to be tested was cut into thin slices with a thickness of 1 mm by wire cutting, and then the front and back sides of the sample were polished with water abrasive paper. In order to ensure the quality of synchrotron radiation imaging, 1000-mesh sandpaper was used in the final grinding process, and the thickness of the final ultra-thin sample prepared was 300 μm. The aluminum alloy ultra-thin sample was cut into a rectangle with a width and length of 8mm×10mm, and ultrasonically cleaned with alcohol solution Sample to ensure surface cleanliness.

[0031] (2) Paint the surface of the ultra-thin sample: In order to avoid crevice corrosion during the electrochemical test, a layer of corrosion-resistant paint is applied on the surface o...

Embodiment 2

[0040] This embodiment discloses an in-situ diffraction experimental method for electrochemical testing of metal materials, taking copper alloy as an example, including the following steps:

[0041] (1) Ultra-thin sample preparation: Process the copper alloy sample to be tested into a thin slice with a size of 10mm×8mm×1mm, and then polish the front and back sides of the sample with water abrasive paper. The final grinding process uses 1000-mesh sandpaper, and the thickness of the final ultra-thin sample is 50 μm. The sample is ultrasonically cleaned with an alcohol solution to ensure a clean surface.

[0042] (2) Paint the surface of the ultra-thin sample: In order to avoid crevice corrosion during the electrochemical test, a layer of corrosion-resistant paint was applied on the surface of the prepared ultra-thin sample, and attention was paid to ensure that the thickness of the paint layer on the surface of the sample was uniform (the thickness was about 50μm).

[0043] (3)...

Embodiment 3

[0050] This embodiment discloses an in-situ diffraction and imaging experimental method for electrochemical testing of metal materials, which is characterized in that it includes the following steps:

[0051] (1) Process the metal material to be tested into a thin slice with a thickness of about 1 mm, and then use water-grinding sandpaper to grind the sample step by step until a rectangular thin slice sample with a thickness of 50-500 μm is required. The thickness of the sample is required to be uniform, and in order to ensure synchrotron radiation imaging Quality, the type of sandpaper in the last grinding process is not less than 1000 mesh. The rectangular thin slice samples were ultrasonically cleaned with alcohol solution to ensure the surface of the rectangular thin slice samples was clean. The length and width of the rectangular sheet sample are less than 20mm×20mm. Due to the limited size of the X-ray spot, the maximum spot size is about 10mm×10mm. In order to collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com