High-strength heat-resistant PA66 undrawn yarn and production process thereof

An undrawn yarn, PA66 technology, applied in the spinning field, can solve the problems of low breaking strength and elongation at break, affecting product quality and production rate, and uneven denier, so as to reduce broken ends and solve the problem of filament Jump out of the problem, the effect of uniform fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

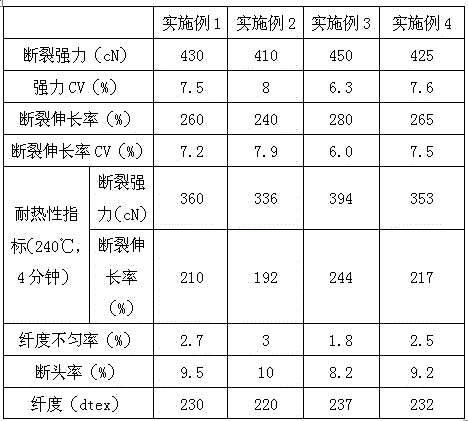

Examples

Embodiment 1

[0046] Example 1 A production process of high-strength heat-resistant PA66 undrawn yarn

[0047] Include the following steps:

[0048] (1) Raw material selection

[0049] Slice with PA66 resin, viscosity 2.65-3.1;

[0050] The resin slices have an oxidation index (YI) ≤ -2, a moisture content (ppm) ≤ 3000, and the appearance requirements do not allow obvious black grains, super long and sticky slices.

[0051] (2) dry

[0052] The slices were dried with a VC352 drum; the drying process was as follows: the drying temperature was 125°C, the drying time was 5.3 hours, the drying vacuum was -0.082MPa, and the moisture content of the slices was dried to 650ppm.

[0053] (3) extrusion melting

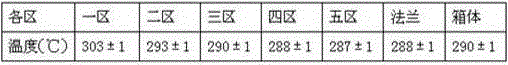

[0054] The temperature of the spinning melt is 290°C, and a screw extruder is used for extrusion melting. The extrusion melting parameters are shown in Table 1 below.

[0055] Table 1 Parameters of extrusion melting

[0056]

[0057] (4) Assembly of components

[0058] Add 150-mesh ...

Embodiment 2

[0071] Example 2 A production process of high-strength heat-resistant PA66 undrawn yarn

[0072] On the basis of Example 1, only the parameters of steps (2), (3), (5), and (6) are changed, and the rest are the same as in Example 1, and the changes are as follows:

[0073] (2) dry

[0074] The slices were dried with a VC352 drum; the drying process was as follows: the drying temperature was 113°C, the drying time was 5 hours, the drying vacuum was -0.079MPa, and the moisture content of the slices was dried to 600ppm.

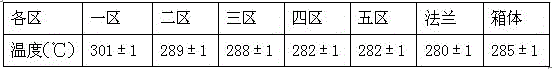

[0075] (3) extrusion melting

[0076] The temperature of the spinning melt is 286°C, and a screw extruder is used for extrusion melting. The extrusion melting parameters are shown in Table 2.

[0077] Table 2 Parameters of extrusion melting

[0078]

[0079] (5) Spinning, cooling and forming

[0080] Component preheating temperature: 314°C, metering pump specification: 2.4ml / r×2, metering pump speed: 22.4 rpm, side blowing wind speed 1.24 m / s, side blowing...

Embodiment 3

[0083] Example 3 A production process of high-strength heat-resistant PA66 undrawn yarn

[0084] On the basis of Example 1, only the parameters of steps (2), (3), (5), and (6) are changed, and the rest are the same as in Example 1, and the changes are as follows:

[0085] (2) dry

[0086] The slices were dried with a VC352 drum; the drying process was as follows: the drying temperature was 117°C, the drying time was 5.2 hours, the drying vacuum was -0.081MPa, and the moisture content of the slices was dried to 625ppm.

[0087] (3) extrusion melting

[0088] The temperature of the spinning melt is 297°C, and the extrusion melting is carried out by using a screw extruder. The extrusion melting parameters are shown in Table 3 below.

[0089] Table 3 Parameters of extrusion melting

[0090]

[0091] (5) Spinning, cooling and forming

[0092] Component preheating temperature: 319°C, metering pump specification: 2.4ml / r×2, metering pump speed: 23.2 rpm, side blowing wind spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com