Electric heating ice-proofing anti-fog transparent conductive film for invisible plane and preparation method thereof

A transparent conductive film, electric heating film technology, applied in chemical instruments and methods, anti-corrosion coatings, other chemical processes, etc., can solve corrosion resistance, weather resistance, poor friction resistance, lack of anti-icing and anti-fog performance, radar reflection effect It can achieve the effect of excellent weather resistance, stable and controllable production process, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

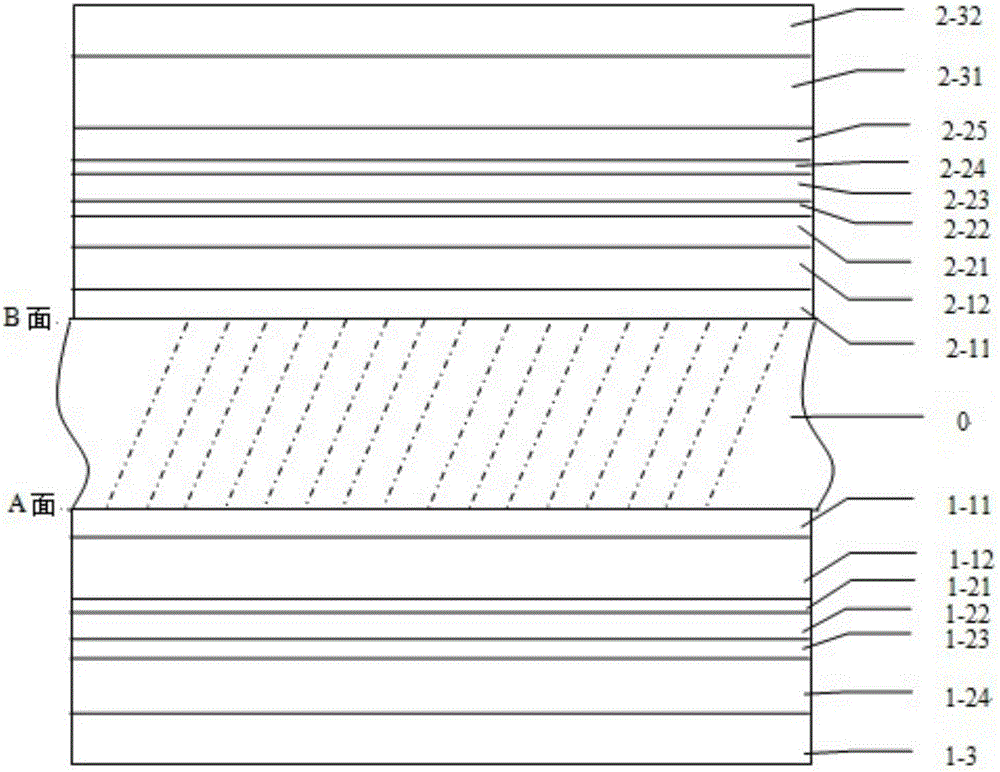

[0034] An electrically heated anti-icing and anti-fog transparent conductive film for a stealth aircraft of the present invention, the electrically heated anti-icing and anti-fog transparent conductive film for a stealth aircraft comprises an A surface and a B surface, and the A surface and the B surface There are different transparent films on the top respectively, the A side is an electric heating film system, and the B side is a stealth function film system;

[0035] The electric heating film system consists of an electric heating adhesion layer, an electric heating function layer and an electric heating protection layer from the inside to the outside of the glass substrate; the stealth function film system consists of a stealth adhesion layer and a stealth function layer from the inside to the outside of the glass substrate and stealth protection layer.

[0036] The two-sided adhesive layer is used to prevent impurity ions from entering the functional layer of the film lay...

Embodiment 2

[0055] The difference between embodiment 2 and embodiment 1 is:

[0056] An electrically heated anti-icing and anti-fog transparent conductive film for a stealth aircraft of the present invention, the electrically heated anti-icing and anti-fog transparent conductive film for a stealth aircraft comprises an A surface and a B surface, and the A surface and the B surface There are different transparent films on the top respectively, the A side is an electric heating film system, and the B side is a stealth function film system;

[0057] The electric heating adhesion layer is composed of two continuous film layers, and the two continuous film layers include a first silicon oxynitride layer 1-11, a first zinc oxide aluminum layer 1-12, and the first oxynitride The thickness of the silicon layer 1-11 is 22nm, the thickness of the first zinc-aluminum oxide layer 1-12 is 75nm,

[0058] The electric heating adhesion layer can improve the adhesion of the film layer and have a certain ...

Embodiment 3

[0072] The difference between embodiment 3 and embodiment 1 is:

[0073] An electrically heated anti-icing and anti-fog transparent conductive film for a stealth aircraft of the present invention, the electrically heated anti-icing and anti-fog transparent conductive film for a stealth aircraft comprises an A surface and a B surface, and the A surface and the B surface There are different transparent films on the top respectively, the A side is an electric heating film system, and the B side is a stealth function film system;

[0074] The electric heating film system consists of an electric heating adhesion layer, an electric heating function layer and an electric heating protection layer from the inside to the outside of the glass substrate; the stealth function film system consists of a stealth adhesion layer and a stealth function layer from the inside to the outside of the glass substrate and stealth protection layer.

[0075] The electric heating adhesion layer is compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com