A two-fluid external mixing nozzle based on high-pressure water

A high-pressure water, two-fluid technology, applied in the direction of liquid injection devices, injection devices, etc., can solve the problems of resource and energy waste, unfavorable industrial application promotion, difficult application, etc., to achieve strong applicability, avoid local high temperature at the feed inlet, The effect of high operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

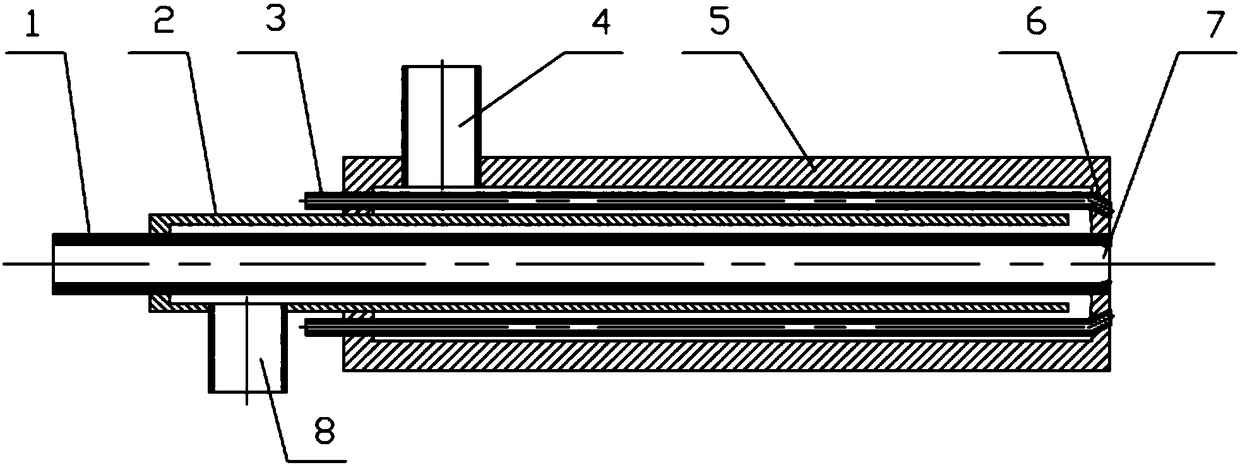

[0021] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , the dual-fluid external mixing nozzle based on high-pressure water provided by the present invention includes a slurry pipe 1, several high-pressure water pipes 3, an isolation pipe 2 and a cooling water pipe 5, wherein the isolation pipe 2 is coaxially sleeved on the outside of the slurry pipe 1, and the cooling The water pipe 5 is coaxially set outside the isolation pipe 2, the high-pressure water pipe 3 is a capillary structure, the high-pressure water pipe 3 is located between the isolation pipe 2 and the cooling water pipe 5, and the high-pressure water pipe 3 is parallel to the slurry pipe 1, and the high-pressure water pipe 3 is along the slurry The circumferential direction of the pipe 1 is evenly distributed. The front end of the slurry pipe 1 is connected with the slurry pump, and the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com