Adhesives and Adhesive Sheets

A technology of adhesives and adhesive layers, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of transparent conductive film corrosion, transparent conductive film resistance value change, affecting pattern visualization, etc., to achieve Excellent step followability and corrosion inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

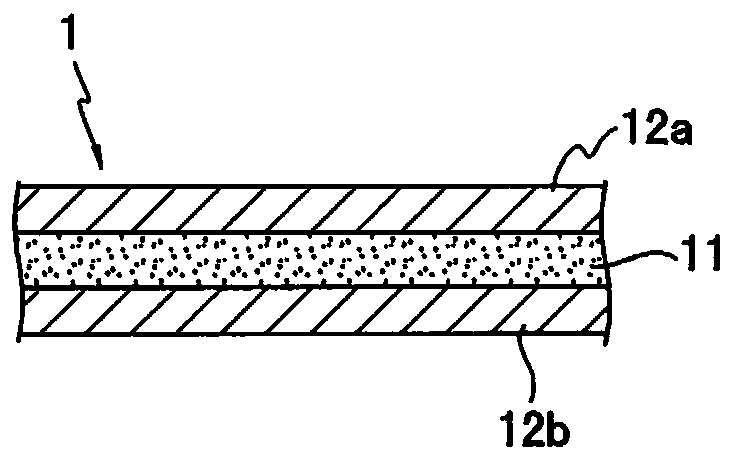

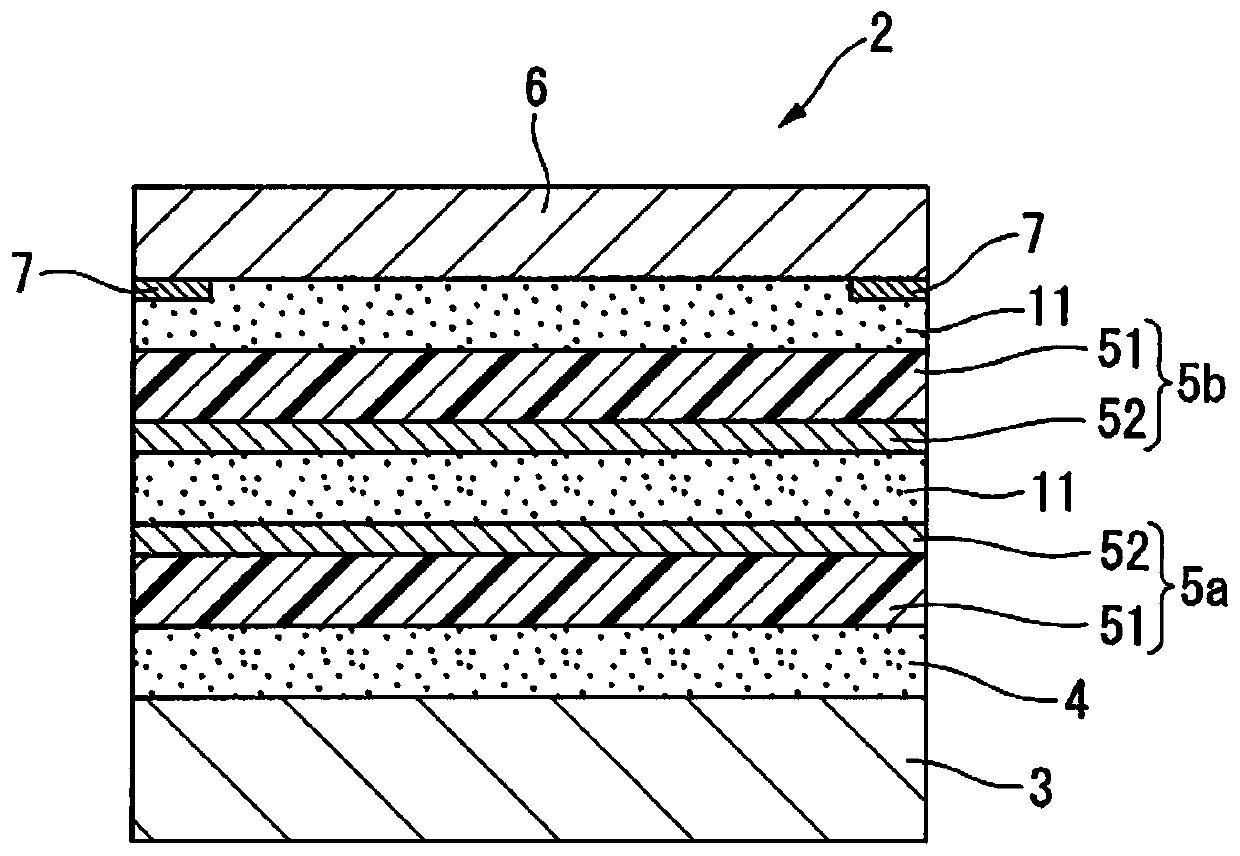

Image

Examples

preparation example Construction

[0078] (5) Preparation of adhesive composition

[0079] The (meth)acrylate copolymer (A) is prepared, and the crosslinking agent (B) is added to the obtained (meth)acrylate copolymer (A), and the silane coupling agent (C) and additives are added as needed , So that the adhesive composition P can be prepared.

[0080] The (meth)acrylate copolymer (A) can be prepared by polymerizing a mixture of monomer units constituting the polymer by a normal radical polymerization method. If necessary, the (meth)acrylate copolymer (A) can be polymerized by a solution polymerization method or the like using a polymerization initiator. As the polymerization solvent, for example, ethyl acetate, n-butyl acetate, isobutyl acetate, toluene, acetone, hexane, methyl ethyl ketone, etc. may be mentioned, and two or more kinds may be used in combination.

[0081] As a polymerization initiator, an azo compound, an organic peroxide, etc. may be mentioned, and 2 or more types may be used together. As the azo ...

Embodiment 1

[0133] 1. Preparation of (meth)acrylate copolymer

[0134] Copolymerize 30 parts by mass of butyl acrylate, 30 parts by mass of 2-ethylhexyl acrylate, 20 parts by mass of methyl methacrylate, and 20 parts by mass of 2-hydroxyethyl acrylate to prepare a (meth)acrylate copolymer (A). As a result of measuring the molecular weight of the (meth)acrylate copolymer (A) by the method described later, the weight average molecular weight (Mw) was 600,000.

[0135] 2. Preparation of adhesive composition

[0136] 100 parts by mass of the (meth)acrylate copolymer (A) obtained in the above step (1) (solid content conversion value; the same below), and trimethylolpropane-modified toluene as a crosslinking agent (B) Diisocyanate (manufactured by Soken Chemical & Engineering Co., Ltd., product name "L-45") 0.25 parts by mass, 3-glycidyl ether propyl trimethoxysilane (Shin-Etsu Chemical Co., Ltd.) as a silane coupling agent Manufacture, product name "KBM-403") 0.2 parts by mass were mixed and fully...

Embodiment 2~24

[0156] [Examples 2-24, Comparative Examples 1-4]

[0157] The type, ratio and polymerization average molecular weight (Mw) of each monomer constituting the (meth)acrylate copolymer (A), the type and amount of crosslinking agent (B), and the silane coupling agent (C) Except that the addition amount was changed as shown in Table 1, an adhesive sheet was prepared in the same manner as in Example 1. In addition, regarding Examples 7 to 9, benzyl benzoate (manufactured by Tokyo Chemical Industry Co., Ltd.) as a refractive index modifier was further added to the adhesive composition. The addition amount is shown in Table 1.

[0158] Here, the weight average molecular weight (Mw) is a weight average molecular weight in terms of polystyrene measured by gel permeation chromatography (GPC) under the following conditions (GPC measurement).

[0159]

[0160] ·GPC measuring device: manufactured by Tosoh Corporation, HLC-8020

[0161] ·GPC column (passed in the following order): manufactured by T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com