Pre-treatment and cleaning method of high-voltage diode nickel-plated silicon wafer

A high-voltage diode and silicon chip technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of environmental protection and safety that are difficult to meet the relevant requirements, the emission of trichlorethylene steaming and washing is large, and the cost of use is high. , achieve great cost advantages, less environmental hazards, and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

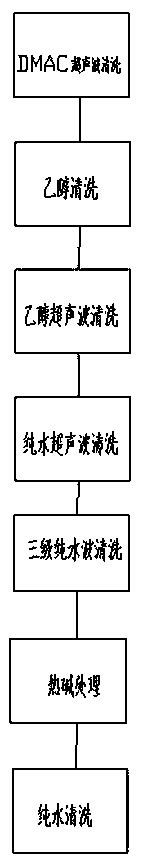

[0031] Below in conjunction with accompanying drawing, content of the present invention will be further described

[0032] As shown in the figure is the process flow chart of the pre-treatment and cleaning method for high-voltage diode nickel-plated silicon wafers.

[0033] Specific implementation process

[0034] 1. Prepare 10% potassium hydroxide solution;

[0035] Weigh 250g of KOH, pour it into the KOH glass square tank, then use a measuring cylinder to measure 2750ml of pure water, pour it in, and stir it fully with a stirring rod to dissolve it.

[0036] 2. Homework preparation;

[0037] 1. Confirm that the liquid volume of the dimethylacetamide ultrasonic tank, ethanol tank, ethanol ultrasonic tank, and running water ultrasonic tank can completely submerge the flower basket with silicon wafers.

[0038] 2. Turn on each ultrasonic switch, and set its power to the "strong" position.

[0039] 3. Put the sandblasted silicon wafers into the flower basket one by one, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com