Precise nickel plating vibration swinging machine for miniature parts

A technology of micro parts and swinging machine, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of insufficient nickel plating and unsatisfactory effect, and achieve the effect of uniform nickel plating, improving surface hardness and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

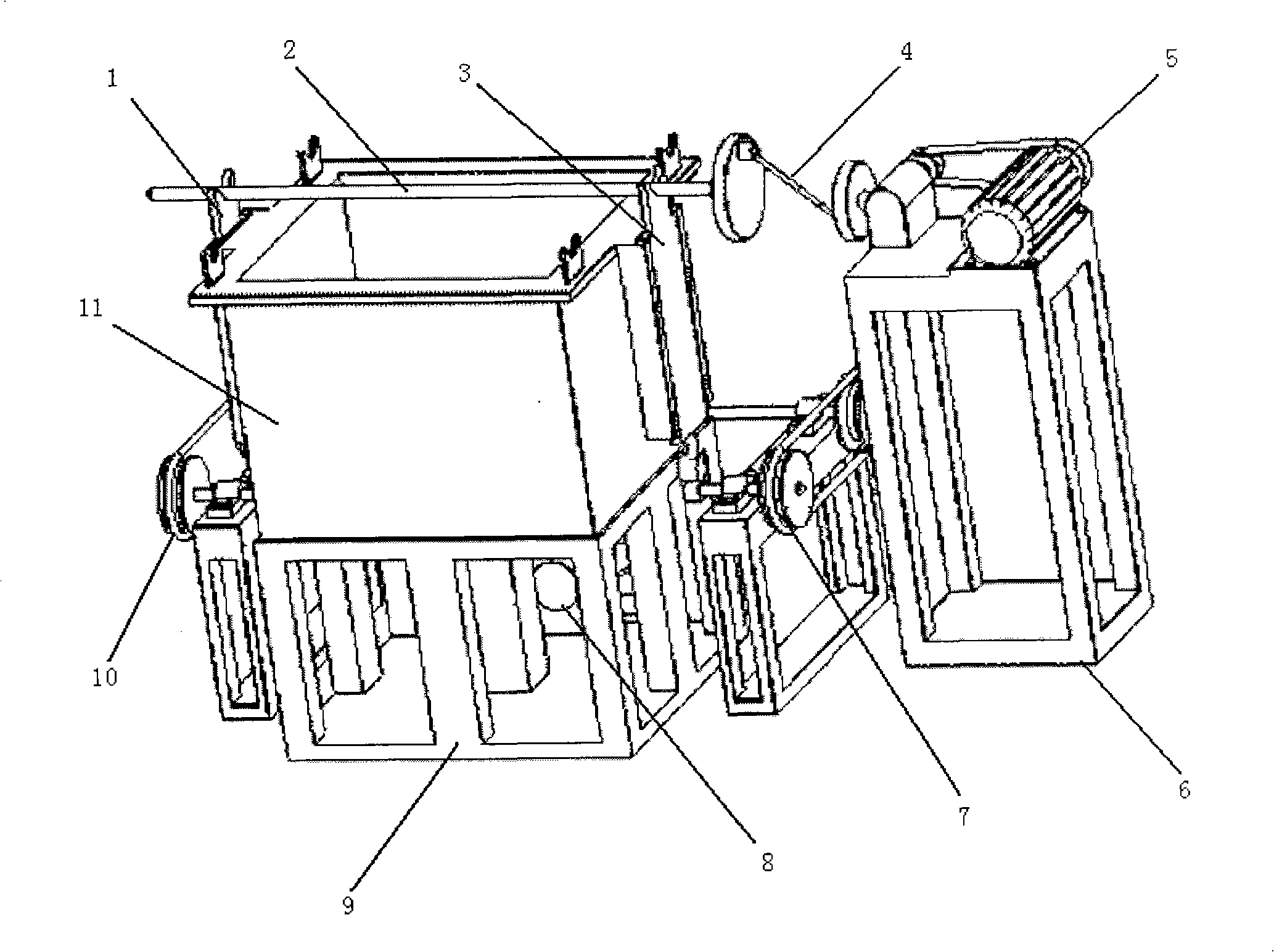

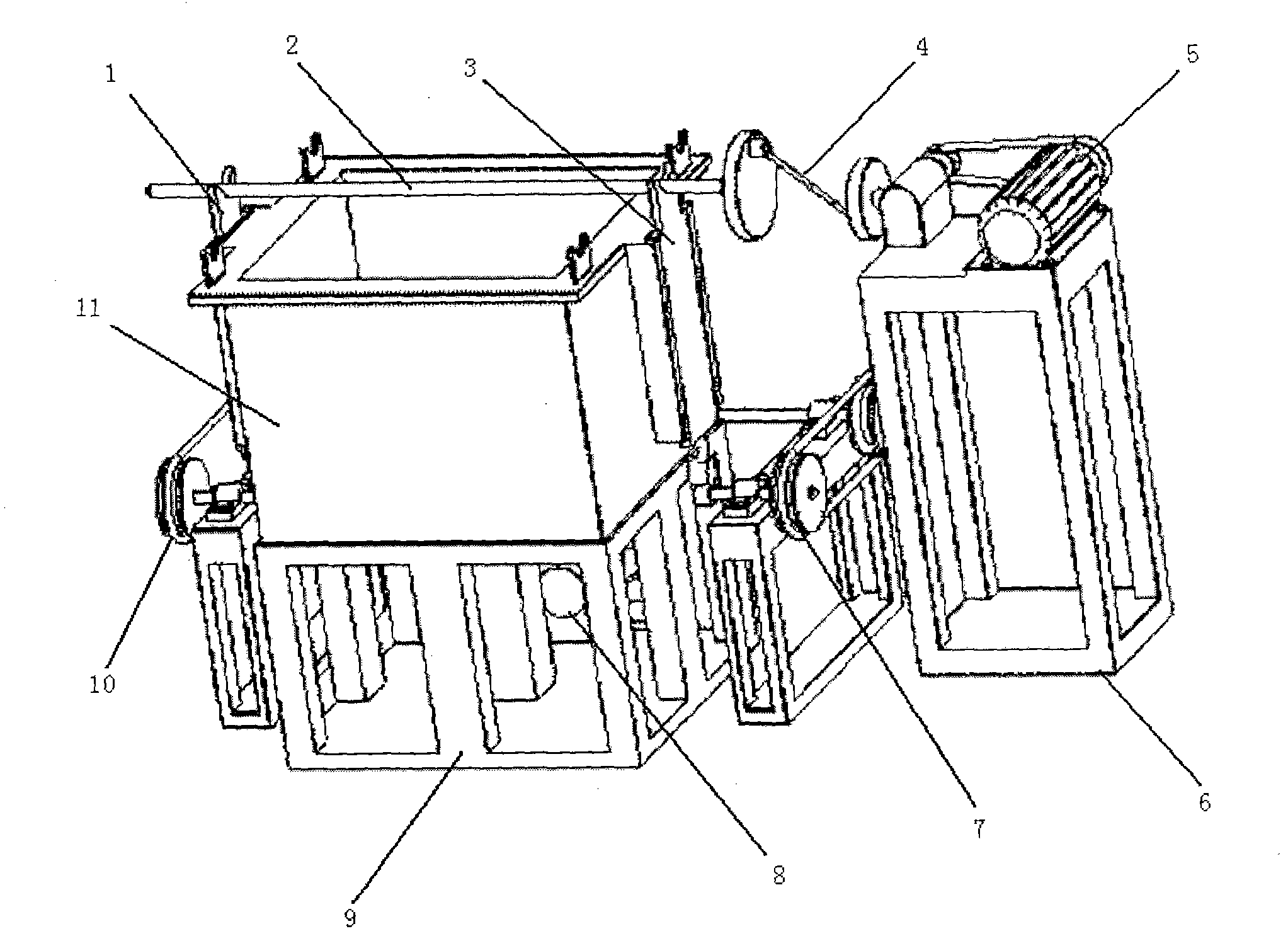

[0012] The core idea of the present invention is: the device drives the eccentric wheel to rotate through the motor, and the support frame connected with the eccentric wheel moves up and down along the support frame under the drive of the eccentric wheel. At the same time, the motor also drives the copper pipe to swing left and right through the connecting rod. Since the plating cylinder is hung on the copper pipe, driven by the copper pipe, the plating cylinder begins to swing left and right, so that the parts in the plating cylinder vibrate left and right. Above-mentioned left and right down, can be that plating tank reaches the effect of vibrating up and down, swinging left and right, can make micro parts fully contact with nickel plating liquid, fully nickel plated.

[0013] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com