Fire-resistant data cable

A data cable and fire-resistant technology, which is applied in the direction of insulated cables, communication cables, cables, etc., can solve problems such as fire resistance, poor mechanical properties, shock absorption effect, poor twisting fire resistance, etc., to achieve easy adhesion, excellent fire resistance, and improved Refractory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

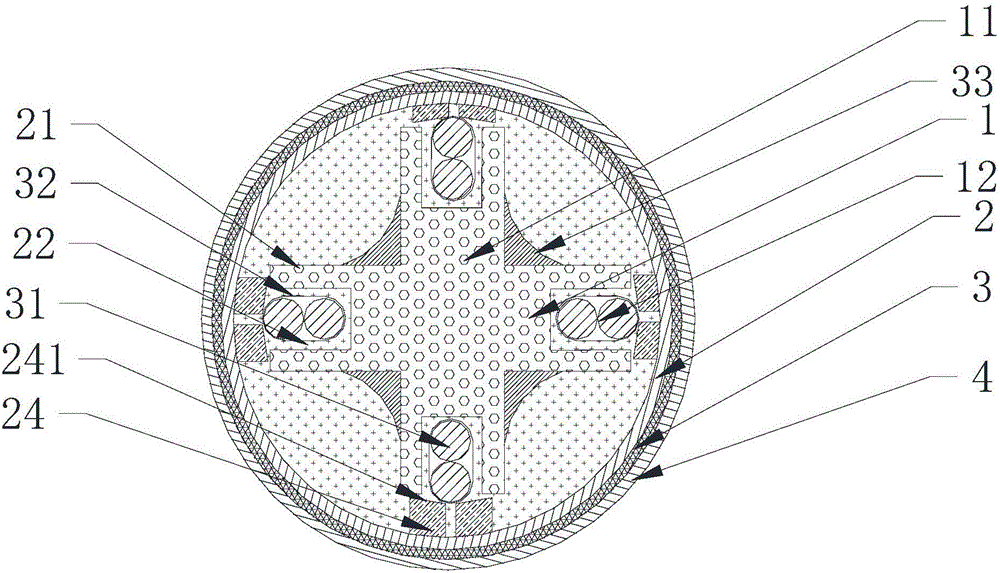

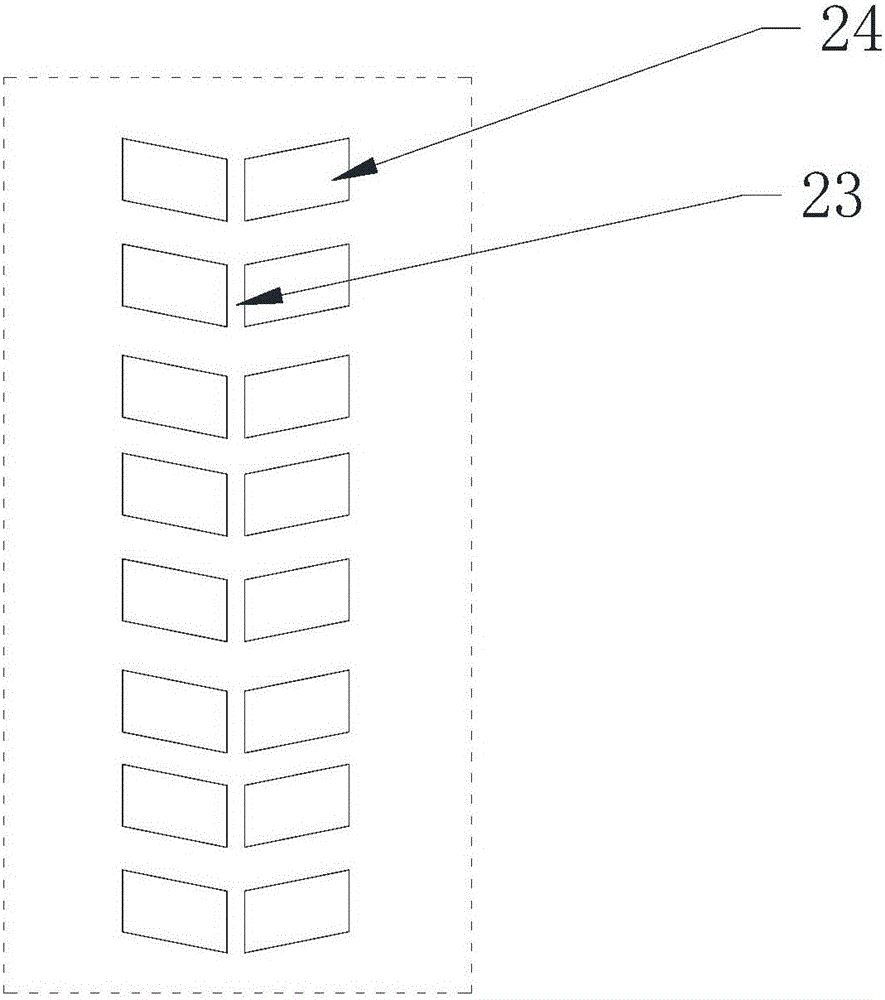

[0022] Embodiment 1: In order to solve the above problems, the present invention discloses a fire-resistant data cable, comprising: a cable inner core 1, an oil-resistant layer 2, a fire-resistant fiber layer 3, and a water-resistant layer 4, the cable inner core 1, the oil-resistant layer 2, The refractory fiber layer 3 and the water-resistant layer 4 are arranged in sequence from the inside to the outside. The cable inner core 1 includes a foamed skeleton 11 and a conductor core group 12. The foamed skeleton 11 includes four symmetrically arranged ridges 21; the The end of the protruding strip 21 is provided with a groove 22 that is recessed inward, and the conductor core group 12 is placed in the groove 22. The conductor core group 12 includes a pair of wires 31 arranged in parallel, and the pair of wires 31 is covered There is an insulating layer 32, and an oil ointment is filled between the cable inner core 1 and the oil-resistant layer 2, and the oil ointment includes dim...

Embodiment 2

[0026] Embodiment 2: The present invention also discloses a fire-resistant data cable, and the length of the protruding strip 21 is 12 mm. The length of the protruding strips 21 is in the range of 8 mm-12 mm, and under the condition of using the foam material, the working strength of the protruding strips 21 is effectively guaranteed.

[0027] In the implementation of the embodiment of the present invention, a foamed skeleton made by foaming a mold is used, a pre-packaged conductor core group is pressed into the foamed skeleton, grease is applied by an oil injection device, and the oil-resistant layer is coated on the inner core of the cable The outer surface of the outer oil-resistant layer is woven and sheathed with a refractory fiber layer, and the outer surface of the refractory fiber layer is injection-molded and covered with a water-resistant layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com