Copper-plated nanometer silver wire touch screen and manufacturing method thereof

A nano-silver wire and manufacturing method technology, applied in the field of electronics, can solve problems such as increased control costs, poor fault tolerance, and difficulties, and achieve the effect of solving unstable electrical contacts, easy automatic production, and realizing automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

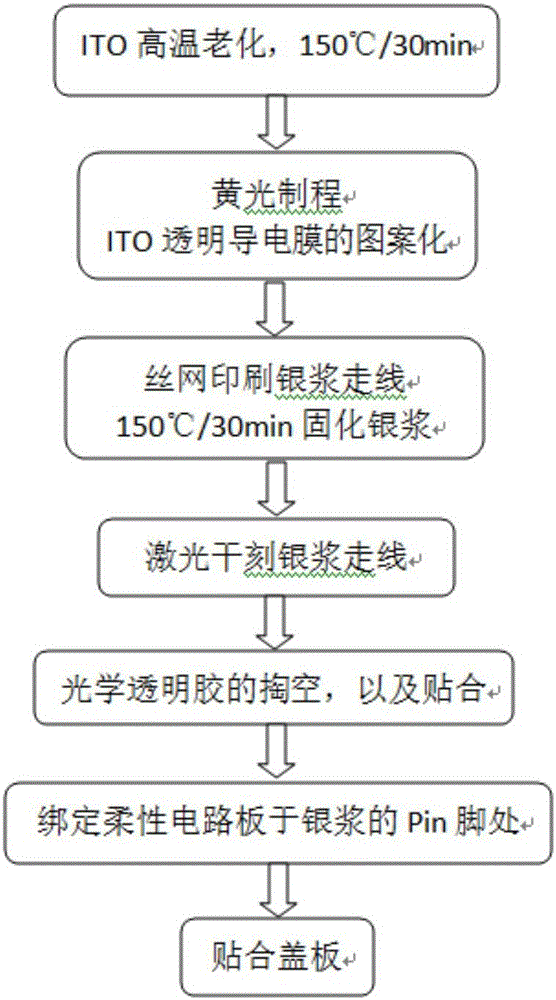

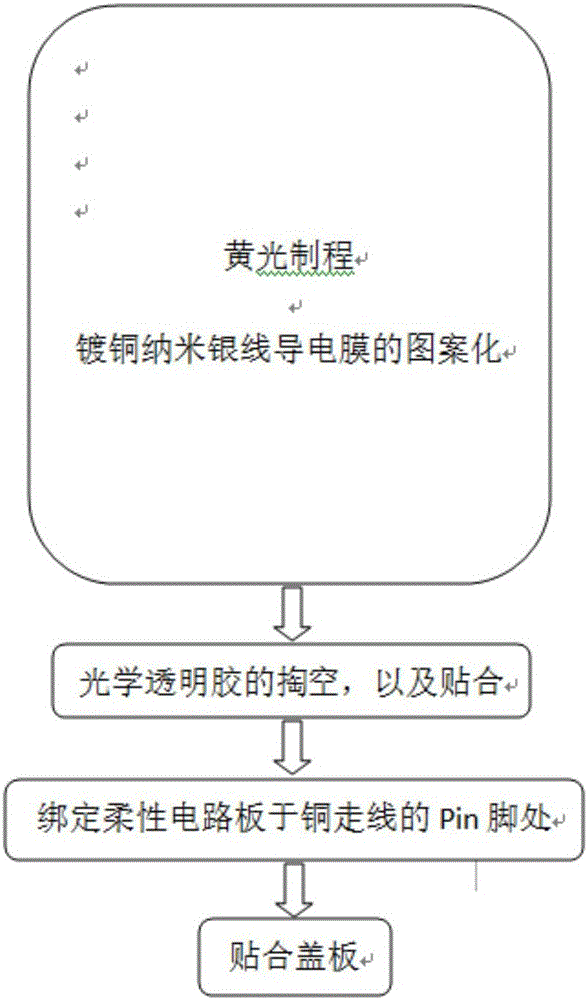

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It can be understood that the specific experimental examples described here are only used to explain the present invention, not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

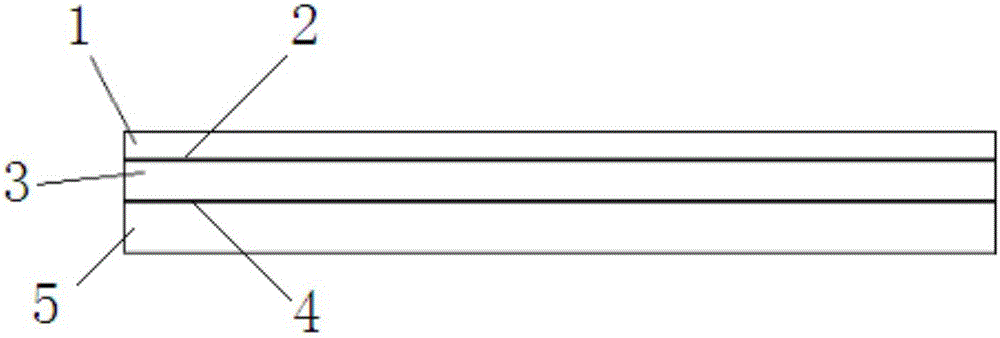

[0022] Please refer to figure 1 as shown, figure 1 A schematic cross-sectional structure diagram of a copper-plated silver nanowire touch screen provided by an embodiment of the present invention.

[0023] The copper-plated silver nanowire touch screen in this embodiment includes a cover plate, an optical transparent adhesive, a touch sensing element and a flexible circuit board. The flexible electric grid is bound to the copper trace Pin on the touch sensing element, and the optical transparent glue is used as a connecting agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com