Iron-based powder core magnet and manufacturing method thereof

A manufacturing method, iron-based powder technology, applied in the direction of permanent magnet manufacturing, inductor/transformer/magnet manufacturing, magnetic objects, etc. Mass production and other issues, to achieve mass production, increase insulation, improve hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

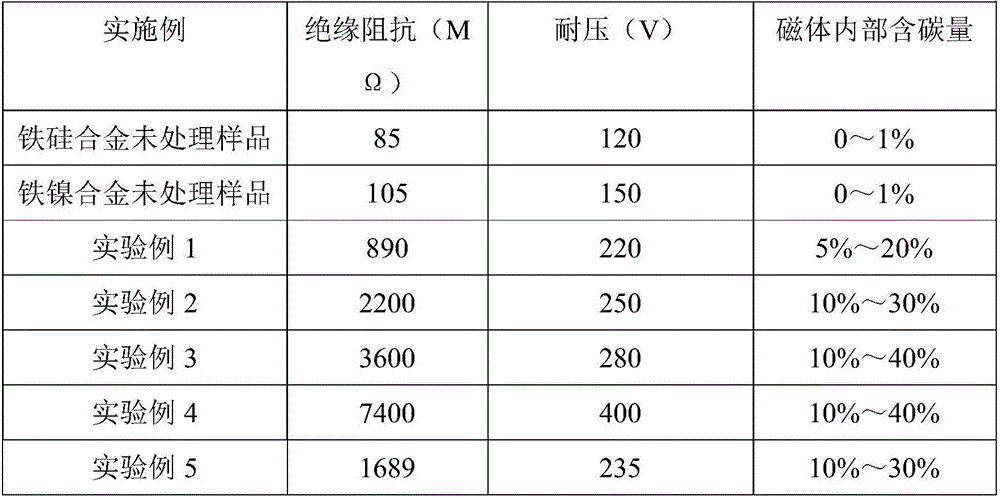

Examples

experiment example 1

[0028] In this experimental example, ethyl acetate + methanol is selected as the carburizing agent, which is equivalent to an organic carbon compound with 4 carbon atoms in a single molecule. Control the proportion of carburizing agent so as to realize the control of carbon potential at 0.5%±0.1%.

[0029] First, load 500pcs of iron-silicon alloy soft magnetic material with length*width*height=2.5*2.15*0.9mm with stainless steel mesh (the aperture size of the stainless steel mesh is slightly smaller than the length and width of the magnet) and fix it with iron wire to prevent the magnet from leaking .

[0030] Secondly, put the loaded 500pcs iron-silicon alloy soft magnetic material in the prepared closed space that can be heated and exchange gas to carry out the adsorption of organic carbon source ethyl acetate + methanol. The specific operation is: first put the sample into the equipment, then pass in the organic carbon source steam, and after the internal air is exhausted, t...

experiment example 2

[0034] In this experimental example, acetone+methanol is selected as the carburizing agent, which is equivalent to an organic carbon compound containing 3 carbon atoms in a single molecule. Control the proportion of carburizing agent so as to realize the control of carbon potential at 0.7%±0.1%.

[0035] First, load 500pcs of iron-silicon alloy soft magnetic material with length*width*height=2.5*2.15*0.9mm with stainless steel mesh (the aperture size of the stainless steel mesh should be slightly smaller than the length and width of the magnet) and fix it with iron wire to prevent the magnet from leaking .

[0036] Secondly, put the loaded 500pcs iron-silicon alloy soft magnetic material in the prepared closed space that can be heated and exchange gas for adsorption of organic carbon source acetone+methanol. The specific operation is: first put the sample into the equipment, then pass in the organic carbon source steam, and after the internal air is exhausted, the internal pr...

experiment example 3

[0040] In this experimental example, propane+methanol is selected as the carburizing agent, which is equivalent to an organic carbon compound containing 3 carbon atoms in a single molecule. Control the proportion of carburizing agent so as to realize the control of carbon potential at 0.6%±0.1%.

[0041] First, load 500pcs of iron-nickel alloy soft magnetic material with length*width*height=2.5*2.15*0.9mm with stainless steel mesh (the diameter of the stainless steel mesh should be slightly smaller than the length and width of the magnet) and fix it with iron wire to prevent the magnet from leaking .

[0042] Secondly, put the loaded 500pcs iron-nickel alloy soft magnetic material in the prepared closed space that can be heated and exchange gas for adsorption of organic carbon source propane+methanol. The specific operation is: first put the sample into the equipment, then pass in the organic carbon source steam, and after the internal air is exhausted, the internal pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com