Hot rolled steel strip for heat stamping and shaping and production method thereof

A technology of hot stamping forming and production method, applied in furnace type, heat treatment furnace, heat treatment equipment, etc., can solve problems such as cracks and flat coils, reduce the amount of phase change expansion, improve the problem of hot-rolled flat coils, and achieve good mechanical uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

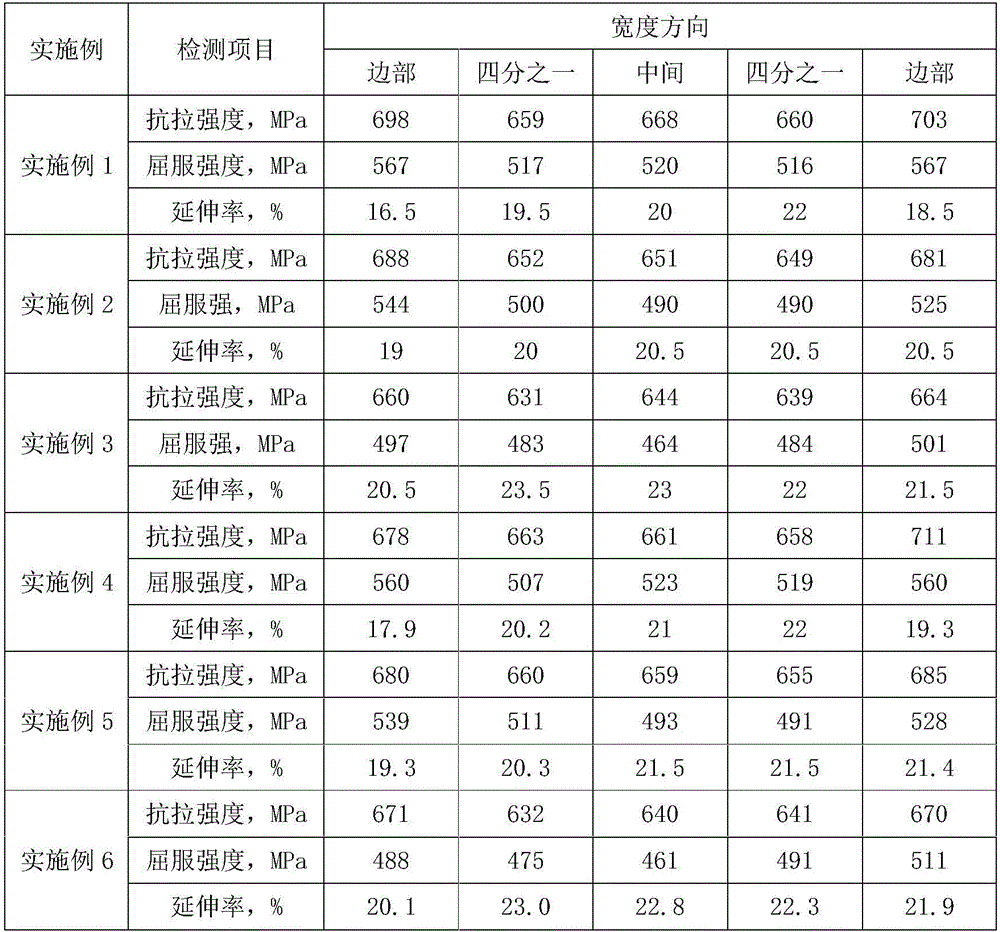

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments;

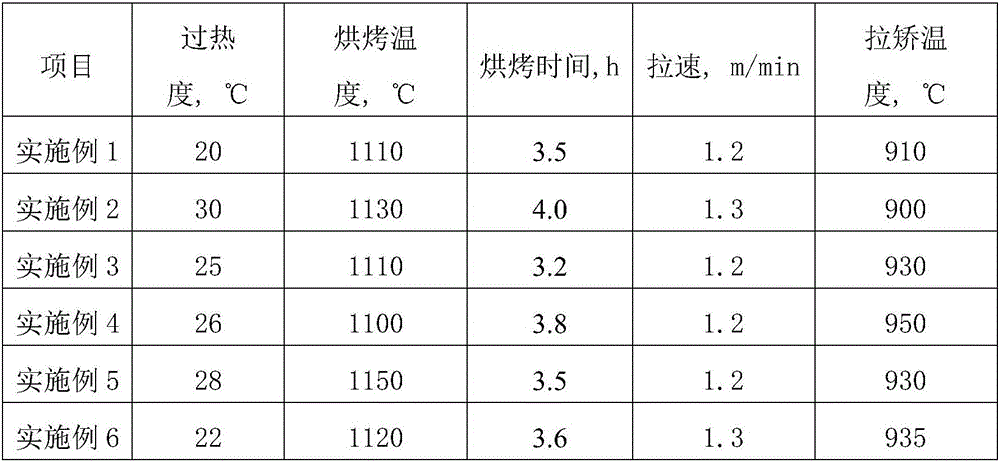

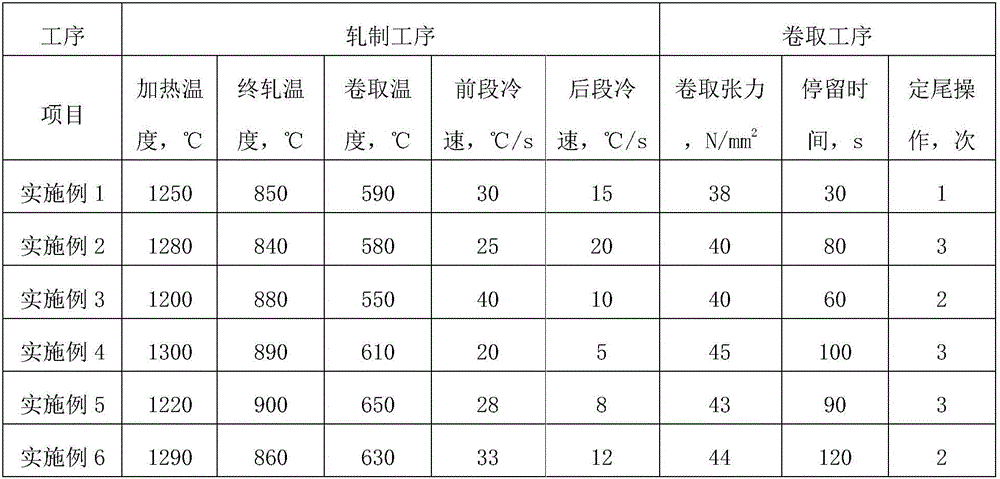

[0028] The process flow of the production method of the hot-rolled steel strip for hot stamping forming is: molten iron desulfurization, converter smelting, LF refining, slab continuous casting, heating, rolling, cooling, and coiling.

[0029] The converter of Examples 1-6 is 100t, LF refining 100t, medium slab continuous casting, continuous casting slab width 800-1550mm, thickness 200mm.

[0030] The specific operation steps and process parameter control of each process are as follows:

[0031] (1) Hot metal desulfurization: After the molten iron ladle is sprayed with magnesium powder, the slag is removed with a slag remover, the surface of the molten iron is free of slag, and the molten iron S<0.003% when entering the furnace;

[0032] (2) Converter smelting:

[0033] a. The temperature of molten iron is 1250℃, S≤0.003%, P≤0.120%;

[0034] b. The main goal of the conversion process is dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com