Tremella composite flocking adhesive

A technology of flocking glue and tremella, applied in adhesives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problems of low viscosity, inconvenient use, and good softness of flocking adhesives , to achieve the effect of good flexibility, not easy to block the nozzle, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

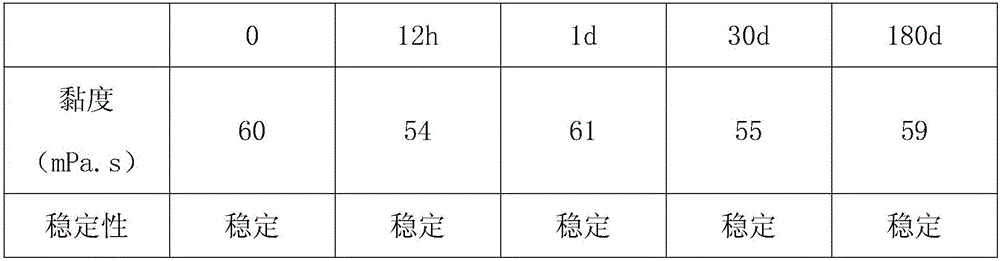

Embodiment 1

[0021] A kind of Tremella composite flocking adhesive, its preparation method is:

[0022] 1) First mix the raw materials: vinyl acetate 500kg; butyl acrylate 50kg; acrylic acid + water 8kg + 10kg, and emulsify 10% of the raw materials;

[0023] 2) Add 600kg of water in the reactor to react with the emulsified raw materials for the first time;

[0024] 3) After the reaction, the remaining raw materials are added dropwise;

[0025] 4) Keep warm for 1 hour afterwards;

[0026] 5) adjust the PH value to be neutral, and obtain the acrylic compound liquid for use;

[0027] 6) Weigh 500g of dried tremella, put it in 10L of 0.3% trehalose solution and let it stand for 18 hours. After the tremella is thoroughly soaked, take it out and grind it evenly.

[0028] 7) Weigh 100 g of ground white fungus, place it in 1 L of calcium chloride boiling solution with a mass concentration of 60%, and treat it for about 80 minutes until most of it dissolves, stir it with a glass rod, and filter ...

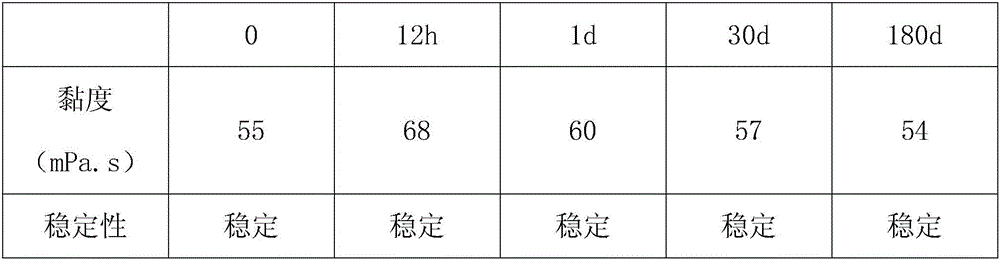

Embodiment 2

[0033] A kind of Tremella composite flocking adhesive, its preparation method is:

[0034] 1) First mix the raw materials: vinyl acetate 500kg; butyl acrylate 50kg; acrylic acid + water 8kg + 10kg, and emulsify 10% of the raw materials;

[0035] 2) Add 600kg of water in the reactor to react with the emulsified raw materials for the first time;

[0036] 3) After the reaction, the remaining raw materials are added dropwise;

[0037] 4) Keep warm for 1 hour afterwards;

[0038] 5) adjust the PH value to be neutral, and obtain the acrylic compound liquid for use;

[0039] 6) Weigh 500g of dried tremella, put it in 10L of 0.3% trehalose solution and let it stand for 20 hours. After the tremella is thoroughly soaked, take it out and grind it evenly.

[0040] 7) Weigh 100 g of the ground white fungus, place it in 1 L of calcium chloride boiling solution with a mass concentration of 60%, and treat it for about 50 minutes until most of it dissolves, stir with a glass rod, and filter...

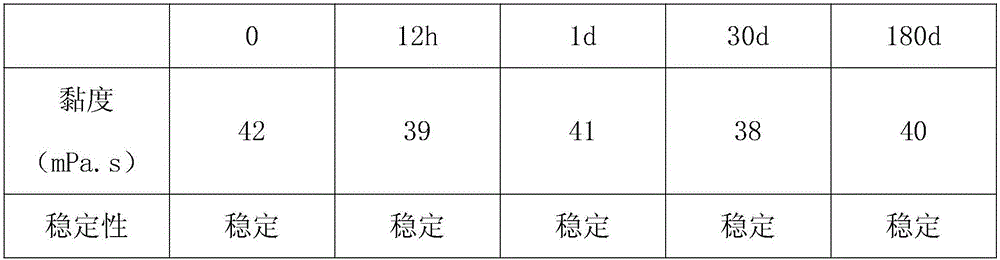

Embodiment 3

[0045] A kind of Tremella composite flocking adhesive, its preparation method is:

[0046] 1) First mix the raw materials: vinyl acetate 500kg; butyl acrylate 50kg; acrylic acid + water 8kg + 10kg, and emulsify 10% of the raw materials;

[0047] 2) Add 600kg of water in the reactor to react with the emulsified raw materials for the first time;

[0048] 3) After the reaction, the remaining raw materials are added dropwise;

[0049] 4) Keep warm for 1 hour afterwards;

[0050] 5) adjust the PH value to be neutral, and obtain the acrylic compound liquid for use;

[0051] 6) Weigh 500g of dried tremella, put it in 10L of 0.3% trehalose solution and let it stand for 19 hours. After the tremella is thoroughly soaked, take it out and grind it evenly.

[0052] 7) Weigh 100 g of the ground white fungus, place it in 1 L of calcium chloride boiling solution with a mass concentration of 60%, and treat it for about 70 minutes until most of it dissolves, stir with a glass rod, and filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com