High-brightness polyarylene sulfide with narrow particle size distribution and preparation method of polyarylene sulfide

A polyarylene sulfide and particle size distribution technology, which is applied in the field of polyarylene sulfide resin and its preparation, can solve the problems of unsuitability for industrial production, complex process, large water consumption, etc., and achieves simplified production process and easy purification. , the effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

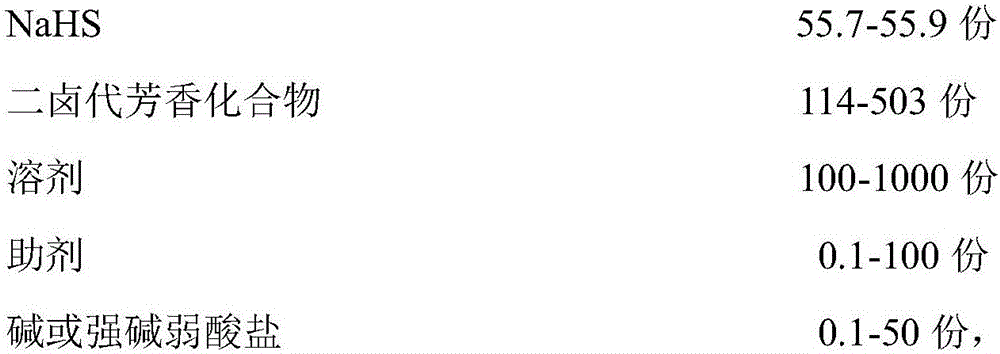

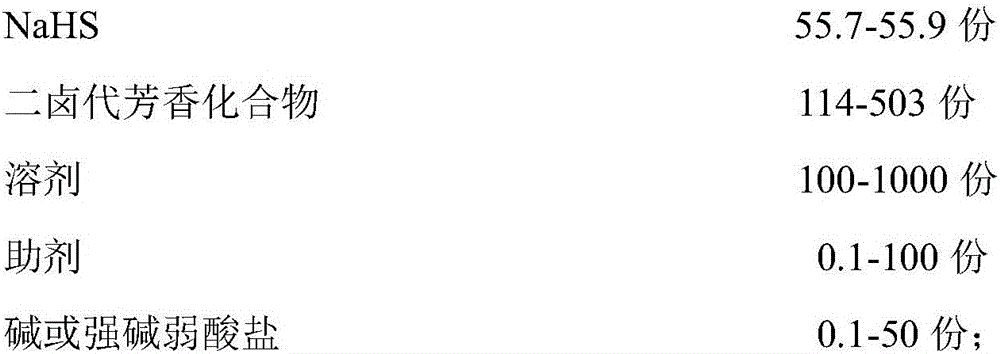

[0039] A preparation method of high whiteness polyarylene sulfide with controllable particle size comprises the following steps:

[0040] Add 0.1-100 parts of additives, 0.1-50 parts of alkali or strong base and weak acid salt, 100-1000 parts of solvent and 55.7-55.9 parts of NaHS into the reaction kettle, and dehydrate at a temperature of 150-200°C for 0.5 -2h, get the NaHS solution after dehydration, when the temperature of the above NaHS solution drops to 130-190°C, add 114-503 parts of dihalogenated aromatic compounds, react at a temperature of 150-230°C for 0.5-3h, at a temperature of 190- Keep at 260°C for 0.5-6h, cool down to 70-180°C, the reacted material is homogenized and crushed by the crushing pump, and then the reaction system is filtered, and water is added to the filtered solid material, washed and dried to obtain polymerization The product (polyarylene sulfide resin), the filtered liquid material is flashed and recovered (the flashed liquid is directly used in ...

Embodiment 1

[0043] Add 0.06kg of lithium acetate, 0.04kg of calcium chloride, 20kg of sodium hydroxide, 1000kg of N-methylcaprolactam and 55.7kg of NaHS into the reactor, and under the protection of nitrogen, dehydrate at a temperature of 150°C for 2 hours to obtain a dehydrated NaHS solution , when the temperature of the above-mentioned NaHS solution drops to 130°C, add 114kg of p-difluorobenzene, react at a temperature of 180°C for 0.5h, keep at a temperature of 250°C for 0.5h, and cool down to 70°C to obtain a reaction product mixture; In the vertical crushing pump, add water accounting for 0.5% of the mixture, and use high-speed shear stirring at 100°C to cause a high-shear liquid flow with a linear velocity of 60m / s to carry out crushing treatment for 5 minutes, and then filter the reaction system , add water in the solid material after filtering, after washing, obtain purified polymer product polyphenylene sulfide resin after drying, its productive rate is 91.3%, and whiteness is 79....

Embodiment 2

[0046] Add 30kg of magnesium acetate, 70kg of sodium phosphate, 50kg of potassium carbonate, 1000kg of 1,3-dimethyl-2-imidazolidinone and 55.8kg of NaHS into the reactor, and dehydrate at 220°C for 0.5h under the protection of nitrogen to obtain After dehydration of the NaHS solution, when the temperature of the above NaHS solution drops to 190°C, add 218kg of 4,4'-difluorobenzophenone, react at a temperature of 150°C for 0.5h, keep at a temperature of 260°C for 6h, and cool down to 180°C To obtain the reaction product mixed solution, place the mixed solution in a vertical kettle, add water accounting for 3% of the mixed solution, and pulverize at 125° C. with a high-shear liquid flow with a linear velocity of 70 m / s caused by high-speed shear stirring Treat for 4 minutes, then filter the reaction system, add water to the filtered solid material, wash and dry to obtain the purified polymer product polyphenylene sulfide ketone resin, the yield is 90.8%, the whiteness is 70.8, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com