Method for preparing polyimide

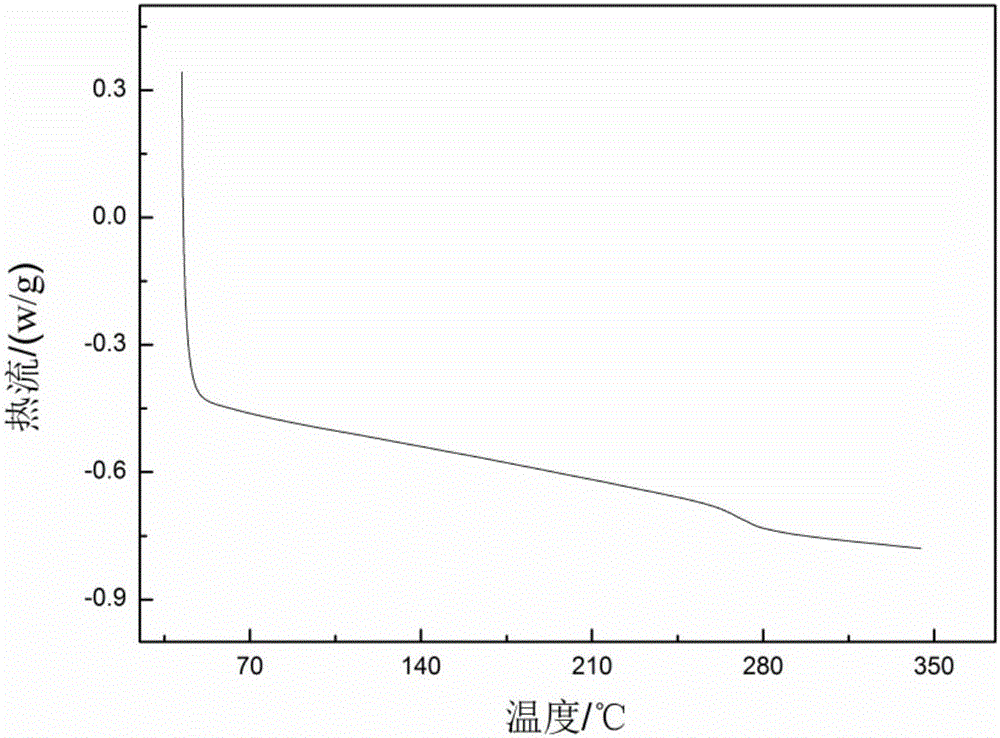

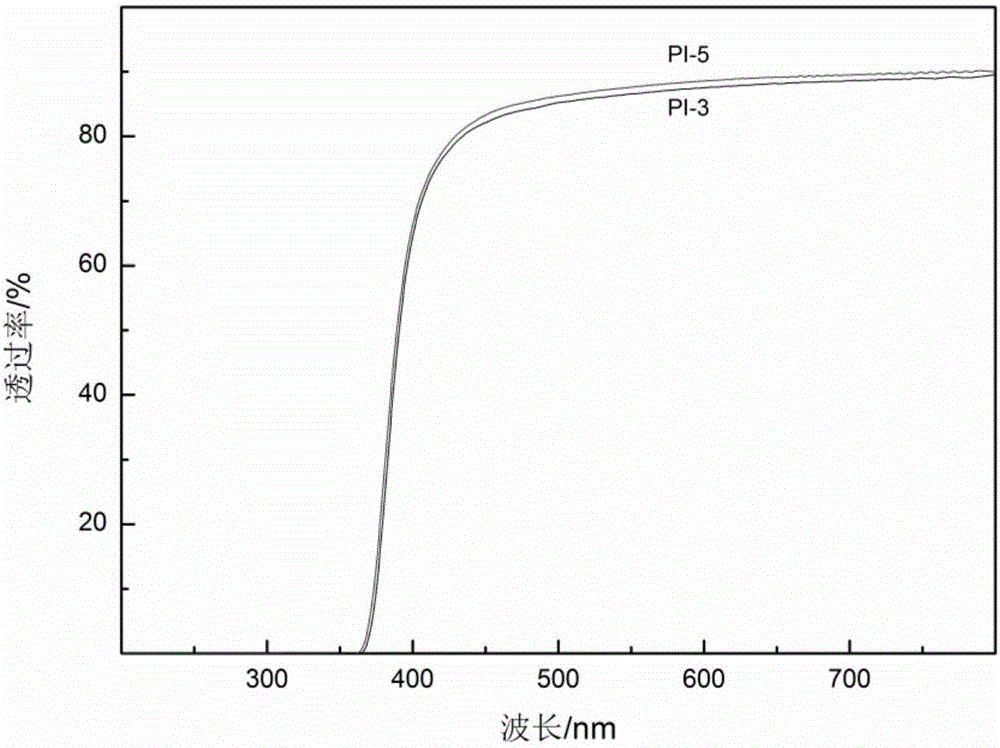

A technology of polyimide and polyamic acid, which is applied in the field of preparing polyimide, can solve problems such as yellowing, and achieve the effects of avoiding yellowing, high transparency, high thermal stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The embodiment of the present invention provides a method for preparing polyimide, the method comprising: under the protection of argon, 2.9558g (0.00923mol) 2,2'-bis Add (trifluoromethyl)diaminobiphenyl and 0.2451g (0.00092mol) 1,1'-bis(4-aminophenyl)cyclohexane mixed diamine (molar ratio 10:1) to 14.88g polar solvent N,N-Dimethylacetamide, stir to dissolve the diamine completely, then add 3.1021g (0.01mol) 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride to the reaction system, and react for 4h Afterwards, 0.149g (0.0006mol) of end-capping agent 4-phenylacetylene phthalic anhydride was added, and the reaction was continued for 24h to obtain a polyamic acid solution.

[0040] Wherein, the structure of 4-phenylacetylene phthalic anhydride is:.

[0041] The mixture of 0.51g triethylamine and 1.61g pyridine is used as a catalyst, the catalyst is added to the polyamic acid solution, and 9.33g dehydrating agent acetic anhydride is added, and the reaction is continued f...

Embodiment 2

[0049] The embodiment of the present invention provides a method for preparing polyimide, the method comprising: under nitrogen protection, 1.6012g (0.005mol) 2,2'-bis( Trifluoromethyl) diaminobiphenyl and 1.6222g (0.006mol) 1,1'-bis(4-aminophenyl)-4-tert-butylcyclohexane mixed diamine (molar ratio 1:1.2) was added to 14.94g Polar solvent N,N-dimethylacetamide, stir to dissolve the diamine completely, then add 3.1021g (0.01mol) 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride to the reaction system After 4 hours of reaction, 0.0984 g (0.0006 mol) of norbornene anhydride was added, and the reaction was continued for 24 hours to obtain a polyamic acid solution.

[0050] Wherein, the structure of norbornene anhydride is:.

[0051] The mixture of 0.29g triethylamine and 1.78g pyridine is used as a catalyst, the catalyst is added to the polyamic acid solution, and 9.33g dehydrating agent acetic anhydride is added, and the reaction is continued for 24 hours to obtain a polyimid...

Embodiment 3

[0055] The embodiment of the present invention provides a method for preparing polyimide, the method comprising: under argon protection, 2.6868g (0.00839mol) 2,2'-bis Add (trifluoromethyl)diaminobiphenyl and 0.4449g (0.00167mol) 1,1'-bis(4-aminophenyl)cyclohexane mixed diamine (molar ratio 5:1) to 15.97g polar solvent After N-methylpyrrolidone was stirred to completely dissolve the diamine, 2.2212g (0.005mol) of 4,4'-hexafluoroisopropylphthalic anhydride, 1.4711g (0.005mol) of 3, 3',4,4'-Biphenyltetracarboxylic dianhydride mixed dianhydride, reacted for 4 hours, added 0.0208g (0.00012mol) of 4-cyanophthalic anhydride, and continued to react for 24 hours to obtain a polyamic acid solution.

[0056] Among them, the structure of 4-cyanophthalic anhydride is.

[0057] The mixture of 2.26g triethylamine and 0.22g pyridine is used as a catalyst, the catalyst is added to the polyamic acid solution, and 9.24g dehydrating agent acetic anhydride is added, and the reaction is continued ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com