Preparation method of aluminum-copper bimetal composite material

A composite material and bimetallic technology, applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of easy generation of cracks and low bonding strength, and achieve the effect of high interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

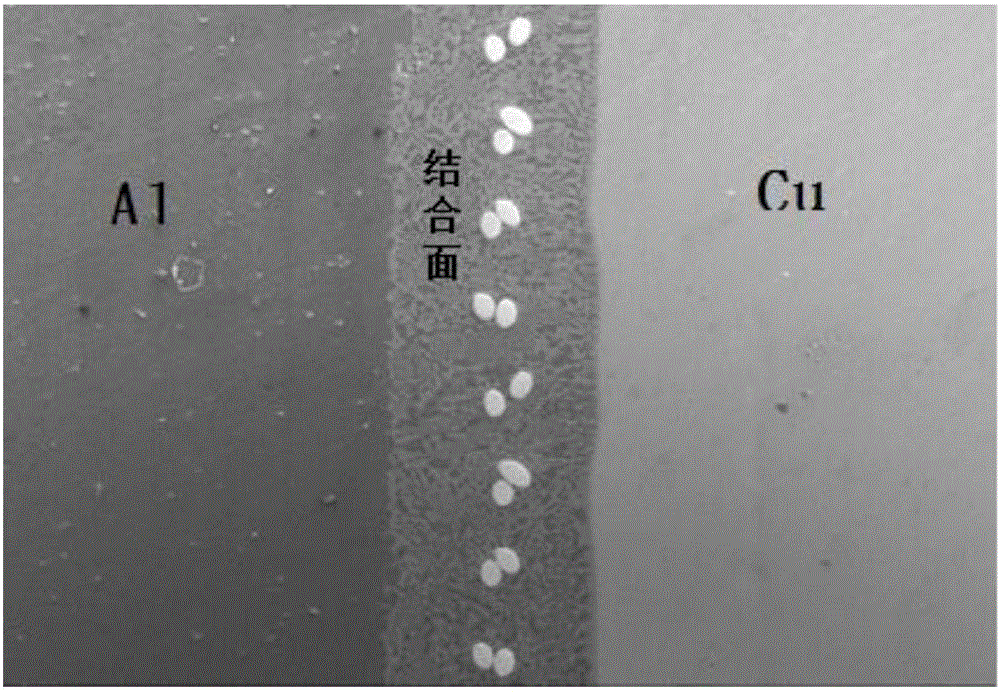

[0013] The preparation method of the aluminum-copper bimetallic composite material of the present invention first pretreats the aluminum block and the copper block respectively, and then places the tungsten fiber net with nickel deposited on the surface between the aluminum and the copper, and places them together on a hot-pressing abrasive tool Diffusion molding of micro-area is carried out in hot pressing to obtain aluminum-copper bimetallic composite materials.

[0014] The specific steps are:

[0015] Step 1, soak pure copper or pure aluminum in 10% nitric acid alcohol for pickling, pickling for 1-5 minutes, and then wash with alcohol for later use

[0016] Step 2, wash the oil stains on the surface of the tungsten fiber mesh with alcohol, and then put it into a physical vapor deposition furnace for vacuuming. When the vacuum degree reaches 6.67×10 -2 After Pa, deposit nickel on the surface of the tungsten fiber mesh for 10-30 minutes;

[0017] Step 3, place the tungsten...

Embodiment 1

[0021] To prepare aluminum-copper bimetallic composite materials, process pure aluminum into a cylinder with a size of Φ30mm×20mm, and prepare pure copper with a size of Φ30mm×30mm;

[0022] Soak pure copper and pure aluminum in 10% nitric acid alcohol for pickling, pickle for 1min, then wash with alcohol and save for later use;

[0023] Rinse the 30-mesh tungsten fiber net with alcohol to wash the oil stains on the surface, and then put it into a physical vapor deposition furnace for vacuuming. When the vacuum degree reaches 6.67×10 -2 After Pa, deposit Ni material on the surface of 30-mesh tungsten fiber mesh for 15 minutes;

[0024] Put pure aluminum, 30-mesh tungsten fiber mesh, and pure copper in the hot-pressing mold in the HVRY-2 high-vacuum high-temperature hot-pressing sintering furnace. In order to prevent oxides from appearing on the interface, first heat the Vacuum the sintering furnace, when the vacuum degree in the vacuum hot pressing furnace reaches 6.67×10 -2...

Embodiment 2

[0026] To prepare aluminum-copper bimetallic composite materials, process pure aluminum into a cylinder with a size of Φ40mm×30mm, and at the same time, prepare pure copper with a size of Φ40mm×30mm;

[0027] Soak pure copper and pure aluminum in 10% nitric acid alcohol for pickling, pickling for 2 minutes, then wash with alcohol and save for later use;

[0028] Rinse the 60-mesh tungsten fiber net with alcohol to wash the oil stains on the surface, and then put it into a physical vapor deposition furnace for vacuuming. When the vacuum degree reaches 6.67×10 -2 After Pa, deposit Ni material on the surface of 60-mesh tungsten fiber mesh for 20 minutes;

[0029] Put pure aluminum, 60-mesh tungsten fiber mesh, and pure copper in the hot-pressing mold in the HVRY-2 high-vacuum high-temperature hot-pressing sintering furnace. In order to prevent oxides from appearing on the interface, first heat the Vacuum the sintering furnace, when the vacuum degree in the vacuum hot pressing fu...

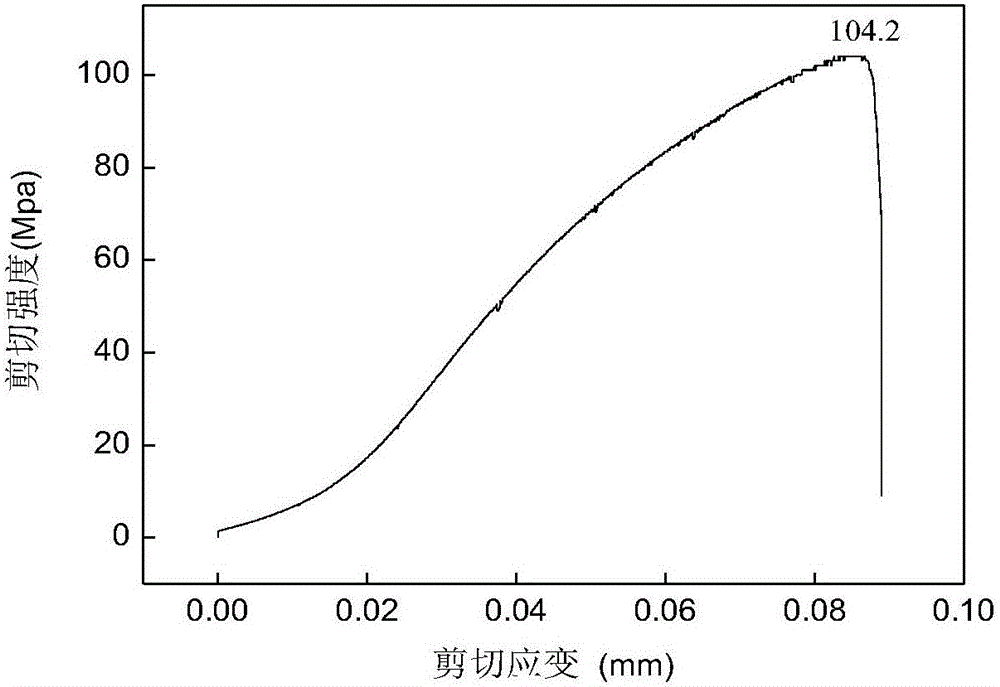

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial shear strength | aaaaa | aaaaa |

| Interfacial shear strength | aaaaa | aaaaa |

| Interfacial shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com