Pressure-proof lycopene microcapsule and preparation method thereof

A lycopene and microcapsule technology, applied in the field of carotenoid microcapsules, can solve the problems of reduced core material protection, poor mechanical strength, not considering the quality requirements of tableting products, etc., so as to reduce voids and improve mechanical strength. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

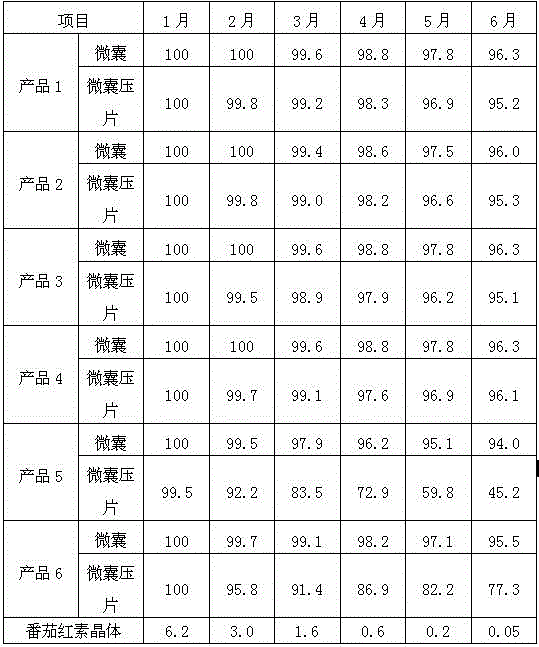

Image

Examples

Embodiment 1

[0025] 1. Add 24g of gum arabic, 36g of gelatin, 100g of sucrose, 1.0g of polysorbate-80, 2.5g of sodium ascorbate and 2.5g of tea polyphenols into 200g of purified water, stir at 80°C for 30 minutes until completely dissolved, then add 2g of natural vitamins E, continue to stir and disperse evenly to obtain an aqueous phase.

[0026] 2. Add 20g of lycopene crystals with a content of 90% into the high-speed shearing water phase, the shearing speed is 10000r / min, the emulsification time is 30 minutes, and then pass through the high-pressure homogenizer twice, with a low pressure of 5MPa and a high pressure of 60MPa.

[0027] 3. Add the emulsion to the feed temporary storage tank, evacuate to 0.09MPa, and stir for 45 minutes.

[0028] 4. One-step granulation of the emulsion by spray-starch fluidized bed drying method, the conditions are: air inlet temperature 45°C, starch fluidized bed blast temperature 65°C, to obtain lycopene microcapsules with a particle size of 40-100 mesh ...

Embodiment 2

[0031] 1. Add 233.3g gum arabic, 466.7g gelatin, 900g glucose, 20g sucrose fatty acid ester, 10g sodium ascorbate and 10g tea polyphenol into 2200g purified water, stir at 65°C for 30 minutes until completely dissolved, then add 40g rosemary to extract matter, continue stirring to disperse evenly, and obtain an aqueous phase.

[0032] 2. Add 200g of lycopene crystals with a content of 90% to the high-speed shearing water phase, the shearing speed is 12000r / min, the emulsification time is 40 minutes, and then pass through the high-pressure homogenizer twice, with a low pressure of 5MPa and a high pressure of 75MPa.

[0033] 3. Add the emulsion into the feed temporary storage tank, evacuate to 0.095MPa, and stir for 30 minutes.

[0034] 4. One-step granulation of the emulsion by spray-starch fluidized bed drying method, the conditions are: air inlet temperature 40°C, starch fluidized bed blast temperature 75°C, to obtain lycopene microcapsules with a particle size of 40-100 mesh...

Embodiment 3

[0037] 1. Add 20kg of gum arabic, 40kg of gelatin, 60kg of isomaltooligosaccharide, 1.2kg of polyglycerol fatty acid ester, 1.27kg of sodium ascorbate and 1.28kg of tea polyphenol into 180kg of purified water, stir at 70°C for 1 hour until completely dissolved, then add 2.25kg of the mixture of natural vitamin E and rosemary extract etc., continue to stir and disperse evenly to obtain the water phase.

[0038] 2. Add 15kg of lycopene crystals with a content of 90% to the high-speed shearing water phase, the shearing speed is 13000r / min, the emulsification time is 45 minutes, and then pass through the high-pressure homogenizer 3 times, with a low pressure of 10MPa and a high pressure of 70MPa.

[0039] 3. Add the emulsion into the feed temporary storage tank, evacuate to 0.09MPa, and stir for 1 hour.

[0040] 4. One-step granulation of the emulsion by spray-starch fluidized bed drying method, the conditions are: air inlet temperature 50°C, starch fluidized bed blast temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com