High-concentration and high-blacking-capability microcapsule-coated red phosphorus flame retardant masterbatch and preparation method thereof

A technology of coating red phosphorus and microcapsules, which is applied in the field of high-concentration and high-blackening microcapsule-coated red phosphorus flame retardant masterbatches and its preparation, can solve the problems of deterioration of material mechanical properties, corrosion of processing equipment, and polymer mechanics. It can improve the chemical stability, improve the flame retardant efficiency and improve the effect of black dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

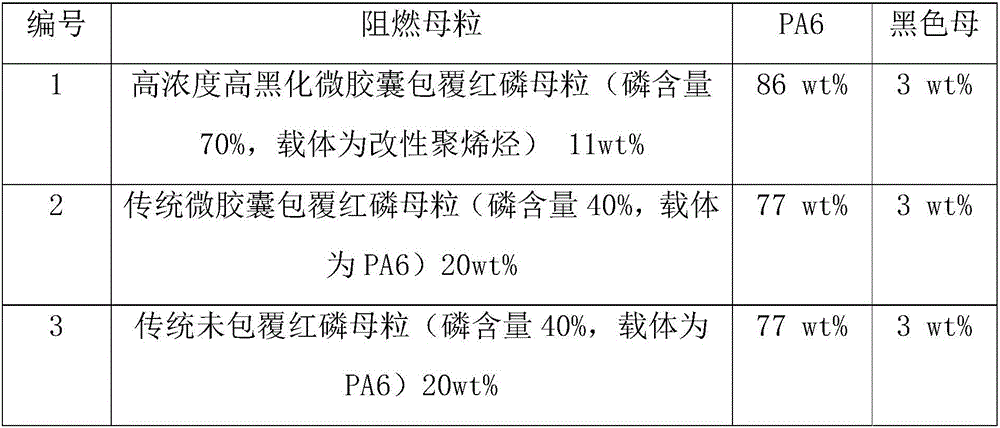

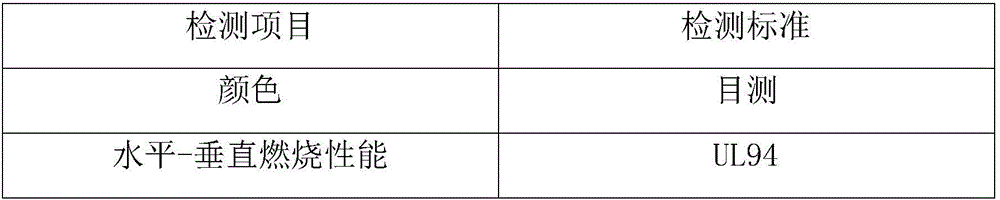

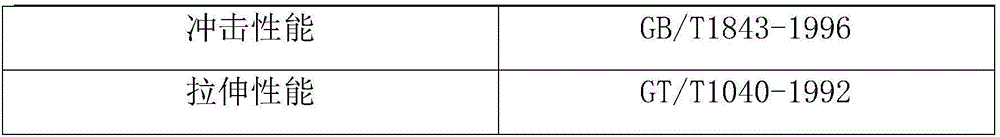

Examples

preparation example Construction

[0052] A preparation method of high-concentration and high-blackening microcapsules coated red phosphorus flame retardant masterbatch, which comprises the following steps:

[0053] 1) Dispersion treatment of red phosphorus: add part of water and red phosphorus into the reaction kettle according to the formula amount, stir evenly, add polyethylene glycol and stir until emulsification;

[0054] 2) Adding aniline hydrochloride: under stirring at normal temperature, slowly add aniline hydrochloride to the system of the above step 1);

[0055] 3) Polyaniline-coated red phosphorus: Dissolve ammonium persulfate in the remaining water to obtain an ammonium persulfate solution, then add the ammonium persulfate solution to the system of the above step 2) at normal temperature, and continue stirring until the Complete response;

[0056]4) Filtration and washing: step 3) washing the reacted product after filtering to obtain microcapsule-coated red phosphorus;

[0057] 5) Drying and gran...

Embodiment 1

[0068] A high-concentration and high-blackening microcapsule-coated red phosphorus flame retardant masterbatch is prepared from coated red phosphorus and modified polyolefin carrier, and the mass ratio of coated red phosphorus and modified polyolefin carrier is 7 : 3; the coated red phosphorus is prepared from red phosphorus powder and coated raw materials, wherein the coated raw materials include water, aniline hydrochloride, ammonium persulfate, polyethylene glycol; wherein each of the red phosphorus and coated raw materials The consumption of component is respectively in parts by weight:

[0069] 60 parts of red phosphorus,

[0070] 120 parts of water,

[0071] 0.5 parts of polyethylene glycol,

[0072] 3 parts of aniline hydrochloride,

[0073] 2.4 parts of ammonium persulfate;

[0074] The preparation method of the high-concentration and high-blackening microcapsules coated red phosphorus flame retardant masterbatch comprises the following steps:

[0075] 1) Grinding...

Embodiment 2

[0083] A high-concentration and high-blackening microcapsule-coated red phosphorus flame retardant masterbatch is prepared from coated red phosphorus and modified polyolefin carrier, and the mass ratio of coated red phosphorus and modified polyolefin carrier is 7 : 3; the coated red phosphorus is prepared from red phosphorus powder and coated raw materials, wherein the coated raw materials include water, aniline hydrochloride, ammonium persulfate, polyethylene glycol; wherein each of the red phosphorus and coated raw materials The consumption of component is respectively in parts by weight:

[0084] 70 parts of red phosphorus,

[0085] 250 parts of water,

[0086] 2 parts of polyethylene glycol,

[0087] 5 parts of aniline hydrochloride,

[0088] 5 parts of ammonium persulfate;

[0089] The preparation method of the high-concentration and high-blackening microcapsules coated red phosphorus flame retardant masterbatch comprises the following steps:

[0090] 1) Dispersion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com