Dodecahedral porous Co3ZnC/C composite material preparation method and use of dodecahedral porous Co3ZnC/C composite material in lithium ion battery

A composite material and dodecahedron technology, applied in the field of new energy materials, can solve problems such as complex preparation process, poor performance, and harsh conditions, and achieve good repeatability, uniform shape, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

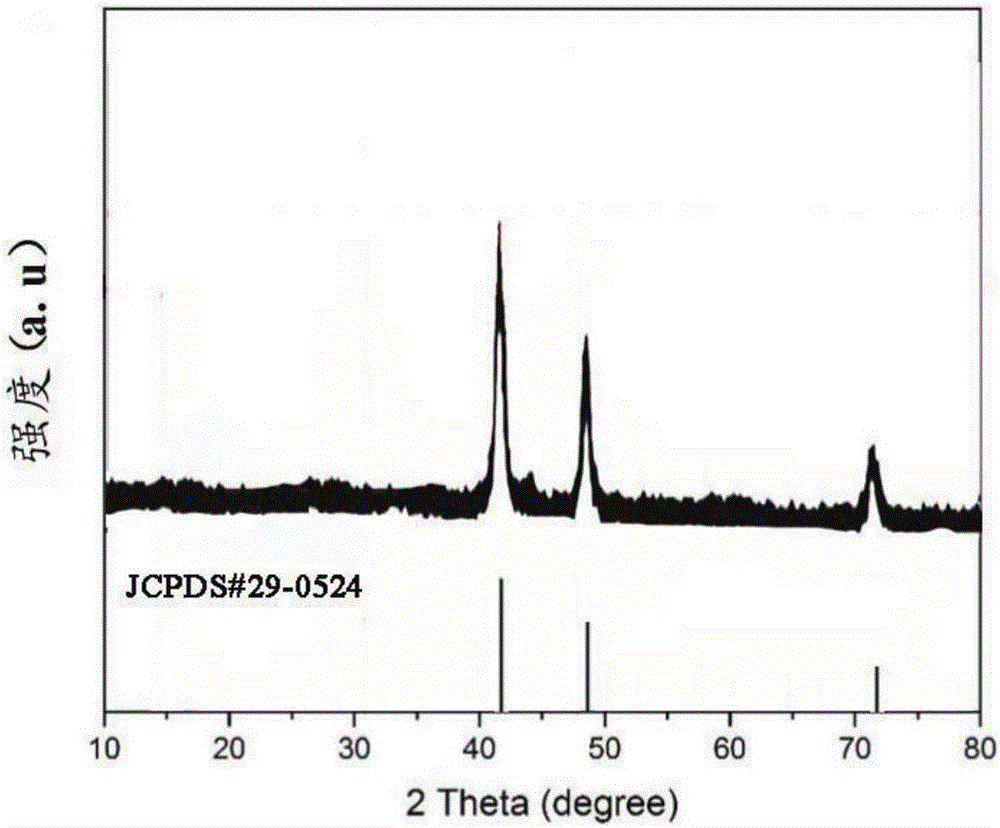

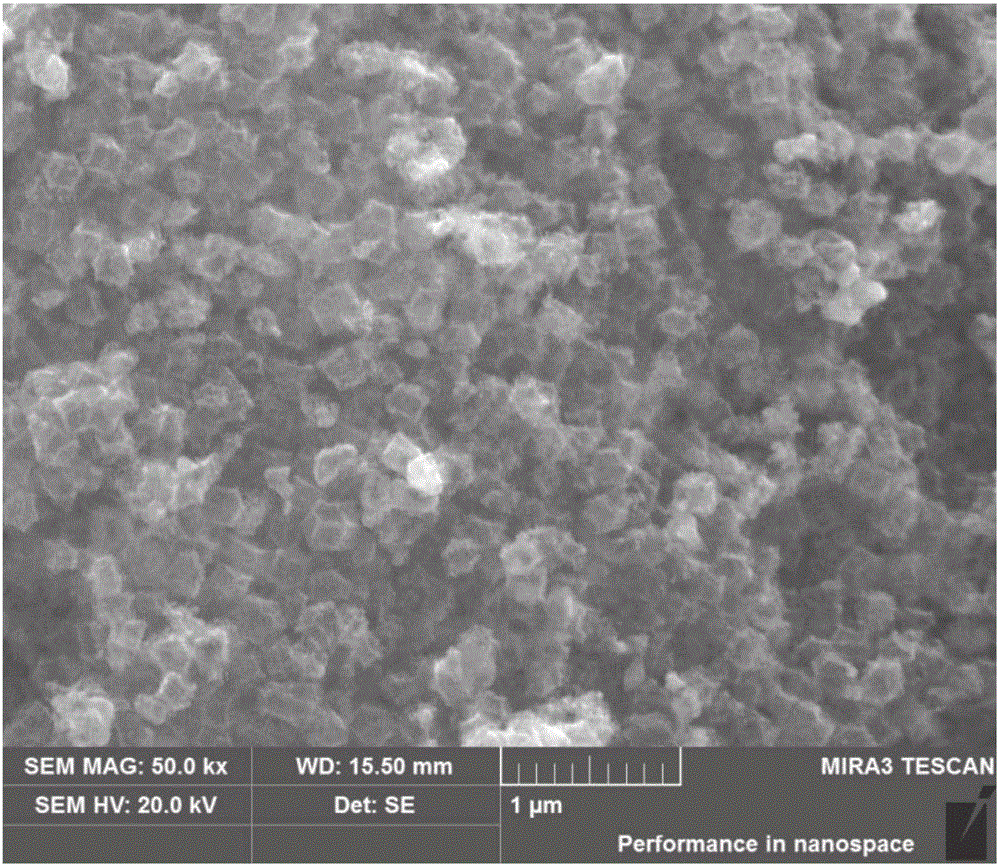

[0058] According to the molar ratio of cobalt source and zinc source is 2: 1, get 3g polyvinylpyrrolidone and 20mmol cobalt nitrate, 10mmol zinc nitrate, dissolve in 200ml methanol to form a solution (dispersion), 160mmol 2-methylimidazole is dissolved in 200ml methanol, The latter was quickly added to the former and fully stirred for 1 hour, and purified at room temperature for 24 hours, resulting in a purple precipitate. The product was washed with methanol, dried in an oven, placed in a quartz crucible, and argon was introduced at 600 ° C. High temperature heat treatment, time is 8h, can get dodecahedral porous Co 3 ZnC / C composites.

[0059] The dodecahedral porous Co prepared by this embodiment 3 ZnC / C composites, Co 3 ZnC / C composite nano-particles are constructed to form a uniform dodecahedral structure rich in pores, and the particle size is 150-250nm. The specific surface area is 745m 2 / g.

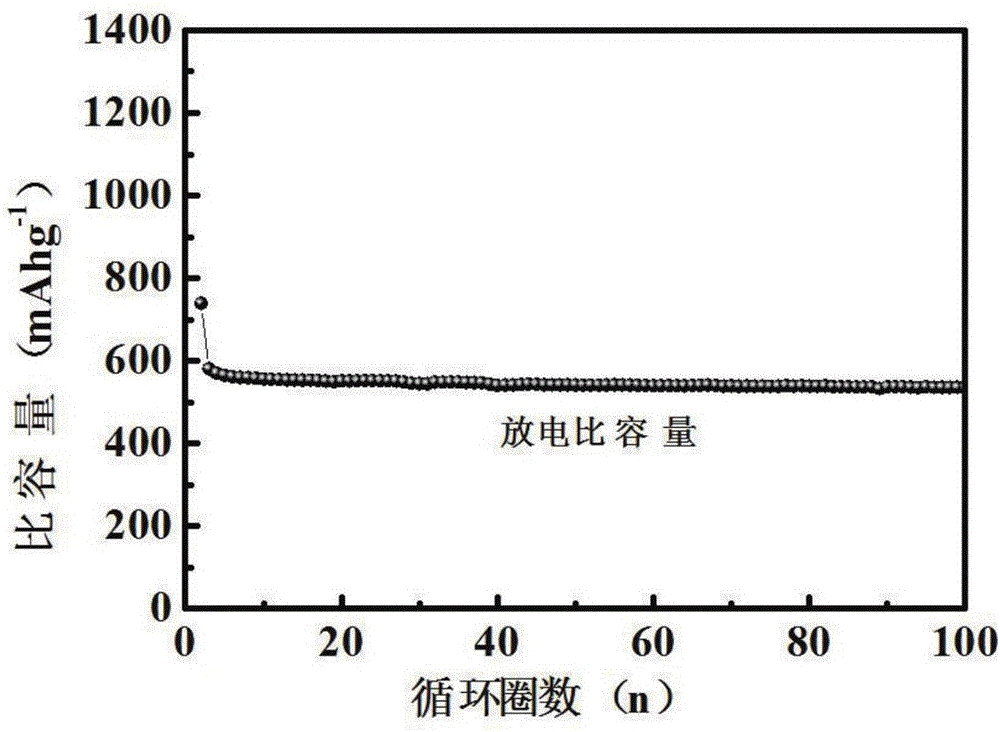

[0060] The lithium-ion battery composite anode material prepared in thi...

Embodiment 2

[0066] According to the molar ratio of cobalt source and zinc source is 1: 1, get 3g polyvinylpyrrolidone and 10mmol cobalt nitrate, 10mmol zinc nitrate, dissolve in 200ml methanol to form a solution (dispersion), 80mmol 2-methylimidazole is dissolved in 200ml methanol, The latter was quickly added to the former and fully stirred for 1 hour, and purified at room temperature for 24 hours, resulting in a purple precipitate. The product was washed with methanol, dried in an oven, placed in a quartz crucible, and argon was introduced at 600 ° C. High temperature heat treatment, time is 6h, can get dodecahedral porous Co 3 ZnC / C composites.

[0067] The dodecahedral porous Co prepared by this embodiment 3 ZnC / C composites, Co 3 ZnC / C composite nano-particles are constructed to form a uniform dodecahedral structure rich in pores, and the particle size is 150-250nm. The specific surface area is 680m 2 / g.

[0068] Dodecahedral porous Co 3 When the electrode made of ZnC / C compos...

Embodiment 3

[0070] According to the molar ratio of cobalt source and zinc source is 1:1, take 2.0g polyvinylpyrrolidone and 10mmol cobalt nitrate, 10mmol zinc nitrate, dissolve in 200ml methanol to form a solution (dispersion), 160mmol 2-methylimidazole is dissolved in 200ml methanol , quickly add the latter to the former and fully stir for 1 hour, stand and purify at room temperature for 24 hours, and produce a purple precipitate, wash the product with methanol, dry it in an oven, place it in a quartz crucible, and blow it with argon at 650°C Perform high temperature heat treatment for 8 hours to obtain dodecahedral porous Co 3 ZnC / C composites.

[0071] The dodecahedral porous Co prepared by this embodiment 3 ZnC / C composites, Co 3 ZnC / C composite nanoparticles are constructed to form a uniform dodecahedral structure rich in pores, and the particle size is 300-400nm. The specific surface area is 720m 2 / g.

[0072] Dodecahedral porous Co 3 The electrode made of ZnC / C composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com