Doped lithium nickel cobalt oxide composite cathode material and preparation method thereof

A composite cathode material, lithium nickel cobalt oxide technology, applied in battery electrodes, electrical components, electrochemical generators and other directions, can solve problems such as restricting the development of high energy density power batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

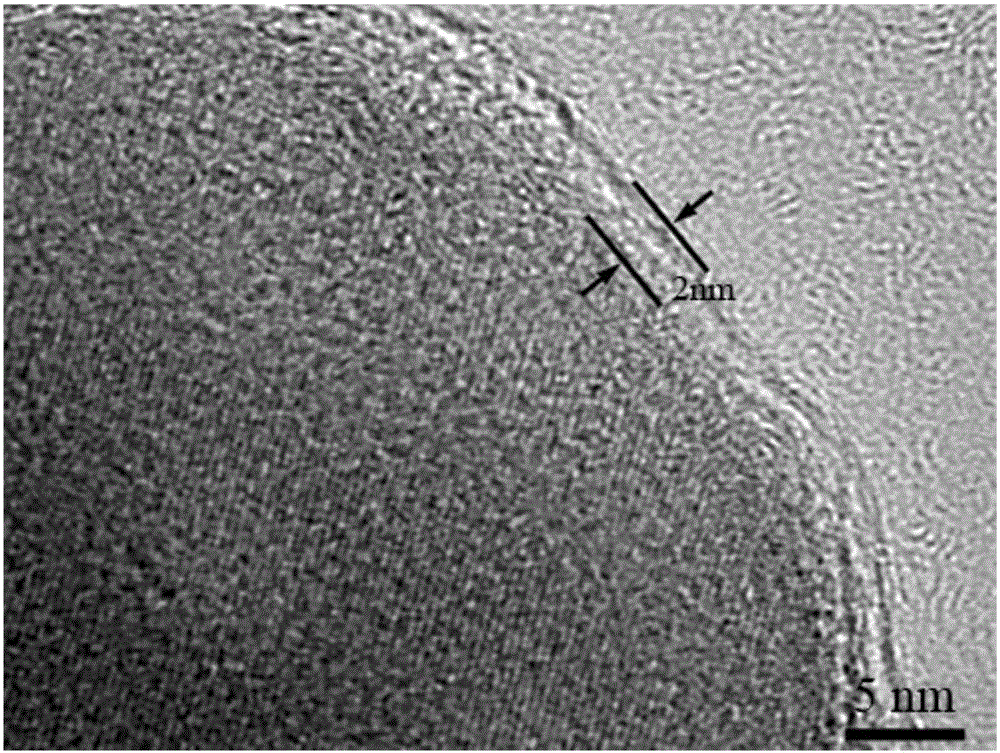

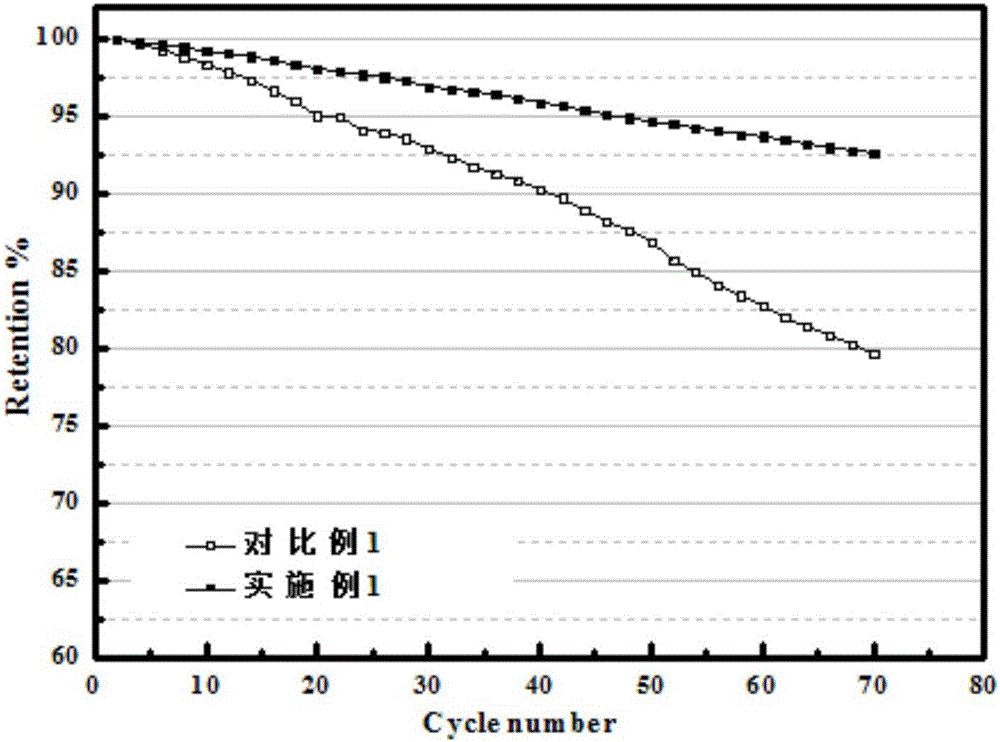

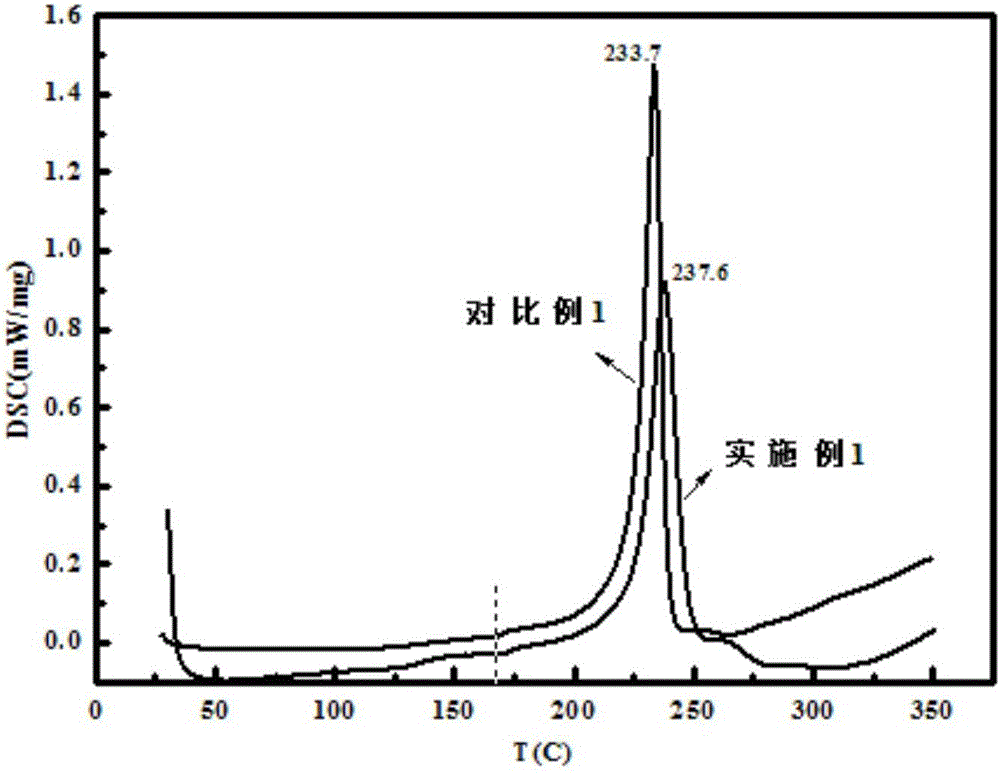

[0024] 1.83kg doped lithium nickel cobalt oxide precursor Ni 0.8 co 0.15 al 0.05 (OH) 2 Add in the reaction kettle that 1mol / L manganese sulfate solution is housed, stir constantly, stirring speed is 500rpm, add the mixed solution of the sodium hydroxide of 0.5mol / L and ammoniacal liquor in the reaction kettle with 30mL / min through metering pump, molar The ratio of ammonia water to sodium hydroxide is 1:20. After the precipitant is added, Mn:NaOH=1:2 by mole in the reaction kettle. After the precipitation is complete, let it stand for 1 hour, filter and collect the solid, and pass the solid through deionized water. Wash and tumble dry. Then mix the dried solid and lithium hydroxide in a high-speed mixer for 60 minutes at a molar ratio of 1:1, then bake at 800°C for 15 hours at a high temperature, cool to room temperature, grind and sieve to obtain surface coating Nickel oxide cobalt aluminum lithium composite positive electrode material with spinel lithium manganese oxide ...

Embodiment 2

[0033] 2.01kg doped lithium nickel cobalt oxide precursor Ni 0.8 co 0.1 mn 0.10 (OH) 2Add in the reaction kettle that 1mol / L manganese sulfate solution is housed, stir constantly, stirring speed is 500rpm, add the mixed solution of 0.5mol / L sodium hydroxide and ammoniacal liquor to the reaction kettle with 30mL / min through metering pump, by mole The ratio of ammonia water to sodium hydroxide is 1:20. After the precipitant is added, Mn:NaOH=1:2 by mole in the reactor. After the precipitation is complete, let it stand for 1 hour, filter and collect the solid, and wash the solid with deionized water ,drying. Then mix the dried solid and lithium hydroxide in a high-speed mixer for 60 minutes at a molar ratio of 1:1, then bake at 800°C for 15 hours at a high temperature, cool to room temperature, grind and sieve to obtain surface coating Nickel oxide cobalt manganese lithium composite cathode material with spinel lithium manganese oxide layer.

Embodiment 3

[0035] 1.01kg doped lithium nickel cobalt oxide precursor Ni 0.8 co 0.15 Al 0.05 (OH) 2 Add in the reaction kettle that 1mol / L manganese sulfate solution is housed, stir constantly, stirring speed is 500rpm, add the mixed solution of 0.5mol / L sodium hydroxide and ammoniacal liquor to the reaction kettle with 30mL / min through metering pump, by mole The ratio of ammonia water to sodium hydroxide is 1:20. After the precipitant is added, Mn:NaOH=1:2 by mole in the reactor. After the precipitation is complete, let it stand for 1 hour, filter and collect the solid, and wash the solid with deionized water ,drying. Then mix the dried solid and lithium hydroxide in a high-speed mixer for 60 minutes at a molar ratio of 1:1, then bake at 800°C for 15 hours at a high temperature, cool to room temperature, grind and sieve to obtain surface coating Nickel oxide cobalt aluminum lithium composite positive electrode material with spinel lithium manganese oxide layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com