Production method of polyurethane elastic fibers

A polyurethane elasticity and production method technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of health damage to operators, large equipment investment, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

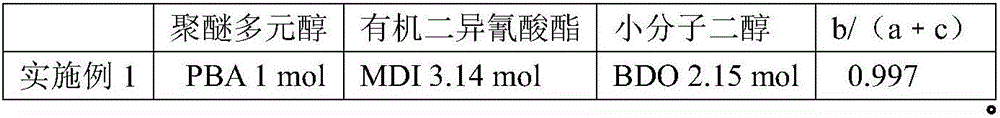

Embodiment 1

[0027] According to the formula ratio in Table 1, first select polyadipate-1,4-butylene glycol ester diol (PBA), phenylmethane diisocyanate (MDI) (heated to 70°C) and 1,4-butanediol (BDO ) (heated to 80°C) to keep each component in a molten state, and an antioxidant (2,6-di-tert-butyl-p-cresol (BHT with a mass ratio of 1:1:1) ), the mixture of antioxidant 1010 and antioxidant 168), carbodiimide and E wax, the mass ratio of the antioxidant, carbodiimide and E wax to component a is 0.3:1000 (antioxidant Oxygen agent: a component = 0.3:1000, carbodiimide: a component = 0.3:1000, E wax: a component = 0.3:1000); after being accurately metered by the metering system, it continuously enters the barrel temperature distribution The double Screw extruder (95 mm diameter, length-to-diameter ratio L / D is 64) mixed for 8 minutes, and at a speed of 100 rpm, carried out bulk melt polymerization, after extrusion, introduced into water, and carried out underwater granulation , so that the po...

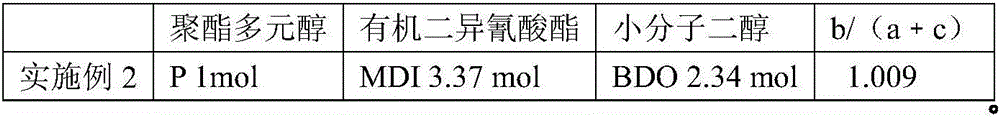

Embodiment 2

[0031] First select polytetrahydrofuran (PTMG), phenylmethane diisocyanate (MDI) (heated to 70°C), 1,4-butanediol (BDO) (heated to 80°C) according to the formula ratio in Table 2, so that each component is in In molten state, add antioxidant (2,6-di-tert-butyl p-cresol (BHT) with a mass ratio of 1:1:1:1, antioxidant 1010, antioxidant 168) during the melting process of component a , the mixture of antioxidant 245), carbodiimide and E wax, the mass ratio of the antioxidant, carbodiimide and E wax to component a is 0.05:1000; after being accurately metered by the metering system, Continuously entering the barrel temperature distribution is 180°C, 180°C, 190°C, 190°C, 190°C, 200°C, 200°C, 220°C, 220°C, 235°C, 235°C, 200°C, 200°C, 190°C, 190°C, 190°C twin-screw extruder (95 mm diameter, length-to-diameter ratio L / D is 64) mixed for 8 minutes, and carried out bulk melt polymerization at a speed of 100 rpm, after extrusion, into In water, carry out underwater granulation, so as to o...

Embodiment 3

[0035] First select polytetrahydrofuran (PTMG) and polyadipate-1,4-butylene glycol ester diol (PBA) according to the formula ratio of the following table 3, phenylmethane diisocyanate (MDI) (heated to 70 ° C), 1, 4-butanediol (BDO) (heated to 80°C), make each component in a molten state, add antioxidant (2,6-di-tert-butyl with a mass ratio of 1:1) during the melting process of component a The mixture of p-cresol (BHT) and antioxidant 1010), carbodiimide and E wax, and described antioxidant is 2,6-di-tert-butyl p-cresol (BHT), antioxidant 1010, antioxidant The mixture of at least two kinds of antioxidant 168 and antioxidant 245, the mass ratio of the antioxidant, carbodiimide and E wax to component a is 0.1:1000; after being accurately metered by the metering system, it is continuously fed into The barrel temperature distribution is 180°C, 180°C, 190°C, 190°C, 190°C, 200°C, 200°C, 220°C, 220°C, 235°C, 235°C, 200°C, 200°C, 190°C, 190°C, 190°C twin-screw extruder (95 mm diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com