Polyacetal fibers, method for producing same and material for drawing

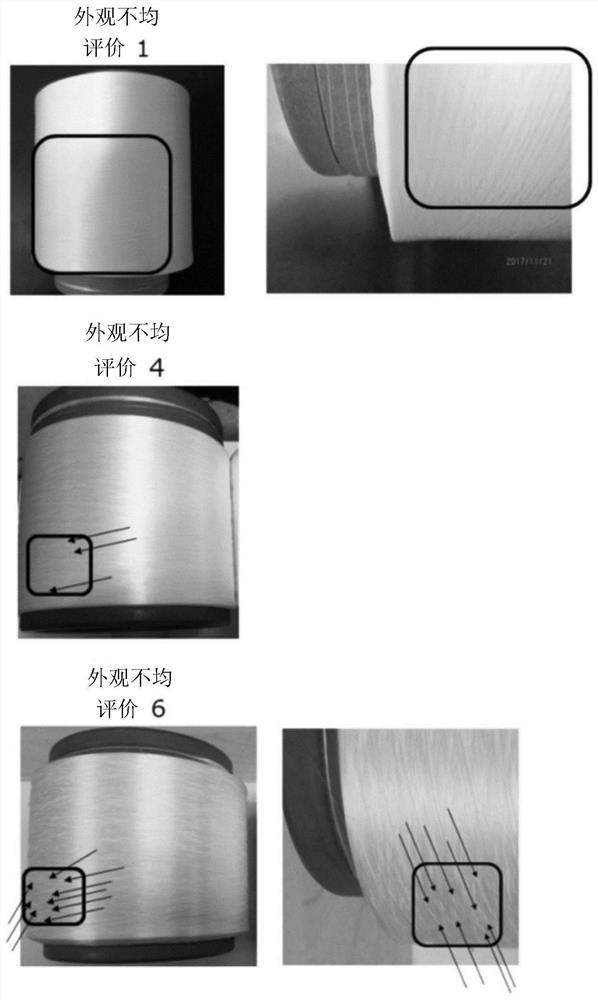

A technology of polyacetal and polyacetal resin, applied in the field of drawing materials, can solve problems such as complicated operation, and achieve the effect of uniform appearance and excellent spinning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

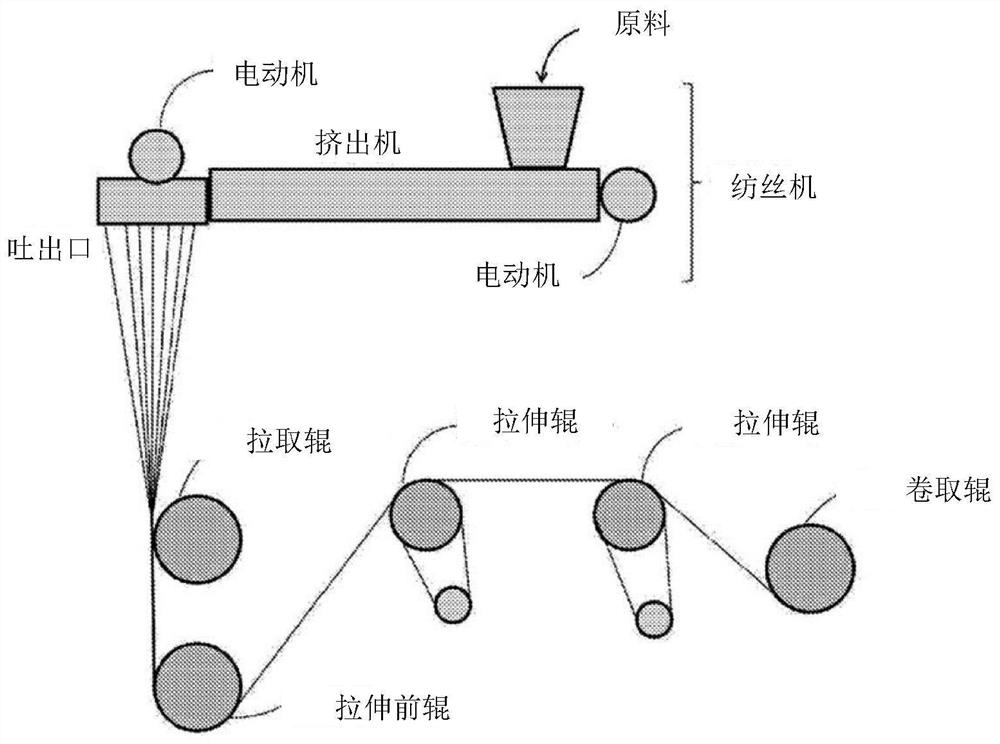

Method used

Image

Examples

Embodiment 1

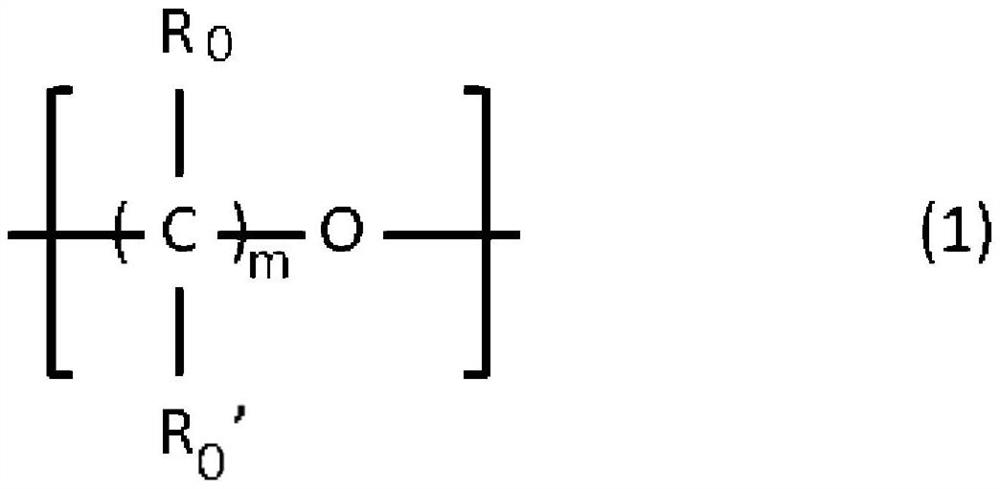

[0153] (1) Preparation of polyacetal

[0154] A polyacetal resin composition (hereinafter, may be referred to as polyacetal (B)) as a raw material of polyacetal fibers is prepared by the following method.

[0155] First, 100 parts by mass of trioxane and 4.0 parts by mass of 1,3-dioxane as a comonomer were mixed, and 0.045 millimoles of boron trifluoride diethyl etherate per 1 mole of trioxane was supplied to the catalyst, Polymerization was carried out in a twin-screw kneader with intermeshing paddles. At this time, 0.12 parts by mass of methylal was added as a viscosity modifier to 100 parts by mass of trioxane to adjust the viscosity. After completion of the polymerization, a small amount of triphenylphosphine benzene solution was added to deactivate the catalyst and pulverized to obtain crude polyacetal.

[0156] After adding and blending additives (Irganox (registered trademark) 245 (manufactured by BASF Japan Co., Ltd.) and melamine (manufactured by Mitsui Chemicals Co...

Embodiment 2

[0165] Except having changed the compounding quantity of the talc into 0.15 mass parts per 100 mass parts of polyacetal (A), it carried out similarly to Example 1, and obtained the polyacetal fiber. Various properties of the obtained polyacetal fibers were measured, and the results are shown in Table 1.

Embodiment 3

[0167] Except having changed the compounding quantity of a talc into 0.25 mass parts per 100 mass parts of polyacetal (A), it carried out similarly to Example 1, and obtained the polyacetal fiber. Various properties of the obtained polyacetal fibers were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com