Diffusion connection technology of laminated composite material and low-alloy steel

A technology of diffusion joining and composite materials, which is used in metal processing equipment, manufacturing tools, welding equipment, etc. to achieve stable and reliable strength and mechanical properties, easy to popularize and apply, and high welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

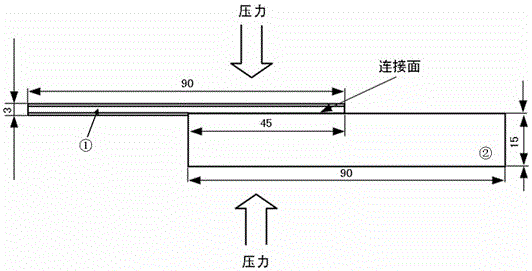

[0021] For the diffusion connection of laminated composite materials with a length of 90mm, a width of 45mm, and a thickness of 3mm, and a Q345 low-alloy steel with a length of 90mm, a width of 90mm, and a thickness of 16mm, the lap joint surface is 90mm×45mm noodle. The process steps are as follows:

[0022] (1) Mechanical processing removes the super nickel coating on the surface of the laminated composite material to be connected, exposing the Ni-Cr base layer (90mm×45mm contact surface) of the surface to be connected, and the surface to be connected is polished with metallographic sandpaper and then wiped with absolute ethanol , to remove oil and debris from the connection surface.

[0023] (2) Use niobium foil with a purity greater than 99.95% as the intermediate layer, the thickness of the niobium foil is 30 μm, and the chemical composition of the niobium foil is: Nb ≥ 99.95% and the rest ≤ 0.05%.

[0024] (3) Place the niobium foil master alloy between the rectangular...

Embodiment 2

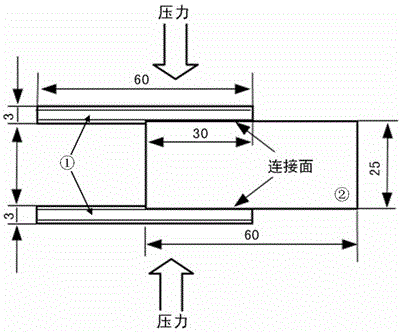

[0032] For the diffusion connection of two laminated composite materials with a length of 60mm, a width of 60mm, and a thickness of 3mm, and a Q345 low-alloy steel with a length of 60mm, a width of 60mm, and a thickness of 25mm, the diffusion connection is carried out on both sides. The lap joint surface is 60mm×30mm double-sided contact surface. The process steps are as follows:

[0033] (1) Mechanical processing removes the super nickel coating on the front and back sides of the laminated composite material to be connected, exposing the 60mm×30mm contact surface of the Ni-Cr base layer on the front and back sides to be connected, and the surfaces to be connected on both sides are polished with metallographic sandpaper Wipe with absolute ethanol to remove oil and debris from the connecting surfaces.

[0034] (2) Use niobium foil with a purity greater than 99.95% as the intermediate layer, the thickness of the niobium foil is 30 μm, and the chemical composition of the niobium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com