Integral type denitration catalyst for selective catalytic reduction of CH4 to NO, and preparation method thereof

A denitration catalyst, an integrated technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. problem, to achieve the effect of low price, good application prospects and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

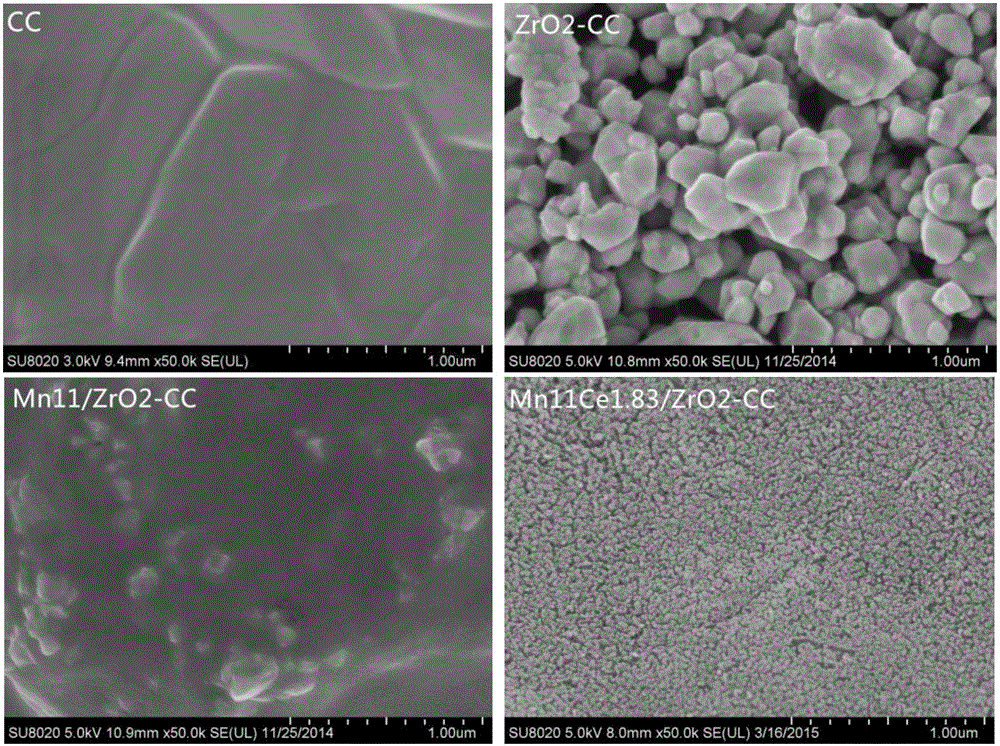

[0031] The preparation of catalyst coating carrier in the present embodiment:

[0032] Based on 10g of zirconia powder, different types of binders were selected, and then zirconia powder, zirconia powder with 8% to 30% of the weight of the binder and distilled water were prepared into a suspension slurry. The data are shown in Table 1. Shown, electric stirring at the same frequency for 10 minutes, after forming a uniform slurry, immerse 2g of the prepared cordierite samples in each slurry, and assist the coating in a vacuum state for 12 hours, take out and blow off the residual slurry of the cordierite channels, and heat at 60°C After baking for 2 hours, it was calcined at 110° C. for 6 hours, and then calcined at 500° C. for 3 hours in a nitrogen atmosphere, so as to prepare a monolithic catalyst carrier.

[0033] In this implementation case, the solidity detection of the integral catalyst coating carrier:

[0034] Take the above-mentioned monolithic catalyst coating carrier...

Embodiment 2

[0040] The preparation of catalyst coating carrier in this embodiment

[0041] Take 2g of sodium carboxymethyl cellulose and add it to 10g of zirconia powder, mix evenly, add 85mL of deionized water, and stir electrically for 10 minutes to form a uniform slurry. Take the cordierite honeycomb carrier and dip it in the slurry, and vacuum for 12 hours to assist the coating. Take out and blow off the remaining slurry of cordierite channels, bake at 60°C for 3 hours, bake at 110°C for 6 hours, and then calcinate at 500°C for 3 hours in a nitrogen atmosphere to obtain a monolithic catalyst-coated carrier.

[0042] The loading of catalyst active component in the present embodiment:

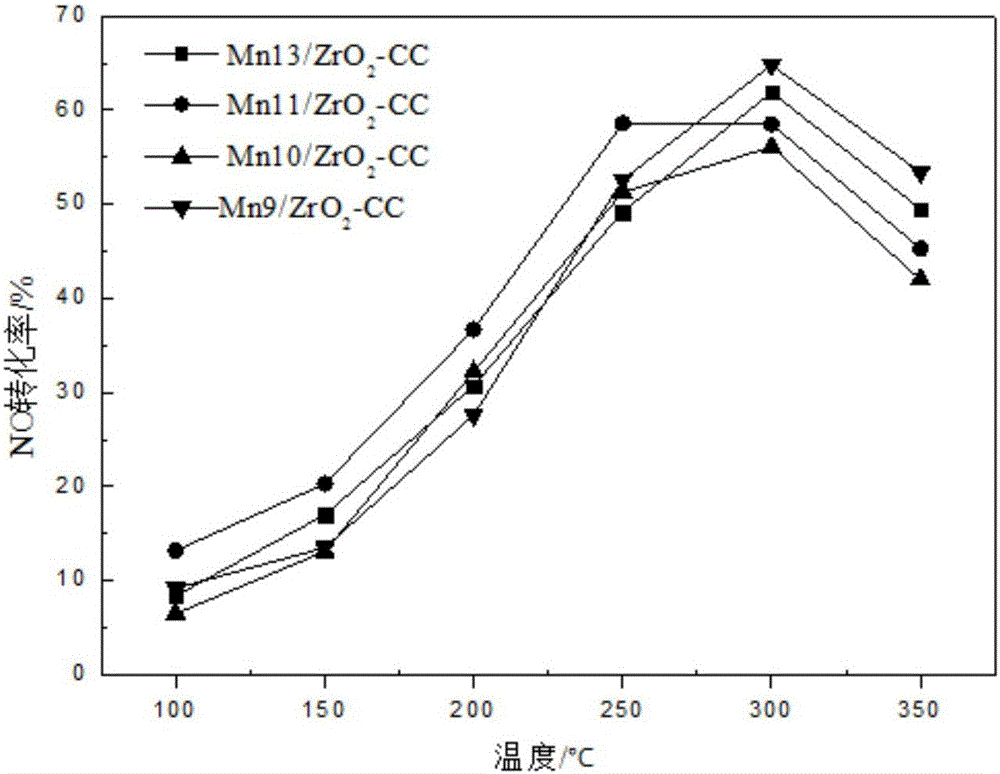

[0043] Configure 50%, 38%, 33% and 28% manganese nitrate solution 50mL to load the above-mentioned catalyst coating carrier respectively, prepare four kinds of catalysts, let stand at normal temperature for 24h, take out and blow off the residual manganese nitrate solution in the channel, and After baki...

Embodiment 3

[0048] The preparation of catalyst coating carrier in the present embodiment:

[0049] Take 2g of sodium carboxymethyl cellulose and add it to 10g of zirconia powder, mix evenly, add 85mL of deionized water, stir it electrically for 10 minutes to form a uniform slurry, take the cordierite honeycomb carrier and dip it in the slurry, vacuum 12h for auxiliary coating, Take out and blow off the remaining slurry of cordierite channels, bake at 60°C for 3 hours, bake at 110°C for 6 hours, and then calcinate at 500°C for 3 hours in a nitrogen atmosphere to obtain a monolithic catalyst-coated carrier.

[0050] The loading of catalyst active component in the present embodiment:

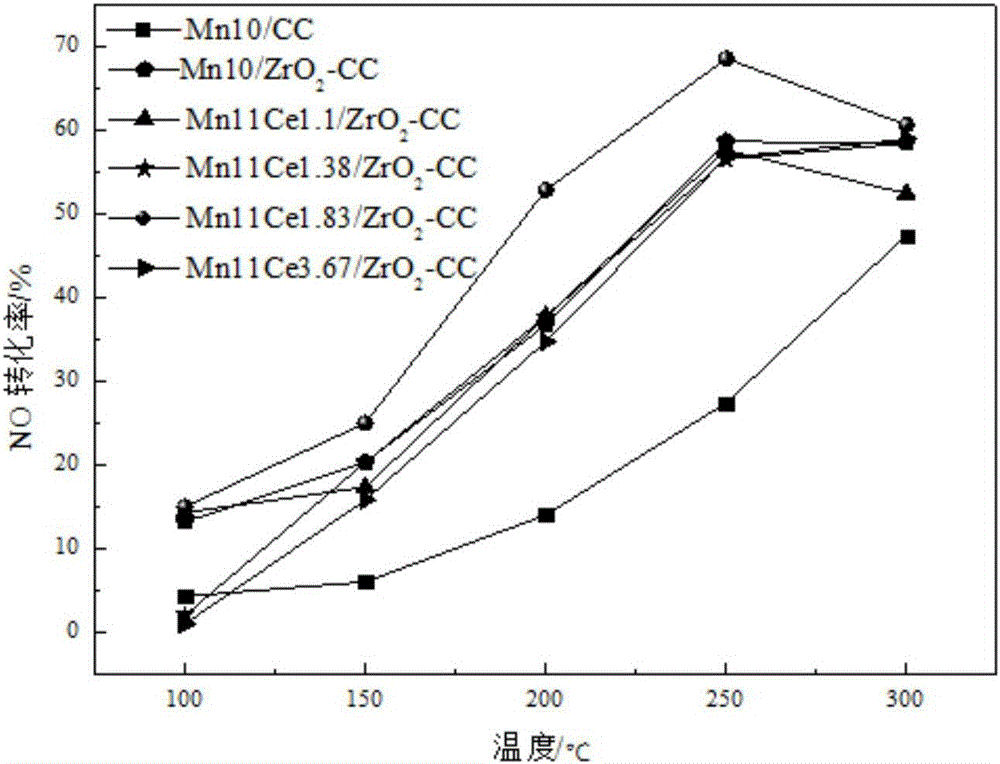

[0051] Add 2.95g, 3.69g, 5.0g and 9.52g of cerium nitrate crystals respectively in 50mL, 38% manganese nitrate solution to make it dissolve, and load the above-mentioned catalyst coating carrier after the two materials are mixed uniformly to prepare four kinds of catalysts, Stand still at 25°C for 24h, take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com