Sputtering target and binding method thereof

A sputtering target and sputtering coating technology, which is applied in the field of sputtering targets, can solve the problems that the backplane components are difficult to be recycled, and achieve the effects of recycling, reducing the use content, and cleaning the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

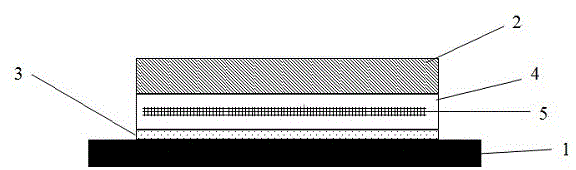

[0026] This embodiment provides a sputtering target, such as figure 1 shown. The backplane component 1 is a copper alloy material, on which a metal indium layer 3 is applied. A conductive adhesive layer 4 is stacked on the metal indium layer, and a non-magnetic metal mesh 5 is arranged in the conductive adhesive layer 4. The non-magnetic metal mesh 5 is a copper mesh, and the target material 2 is bonded on the conductive adhesive layer.

[0027] The binding method is carried out as follows: First, place the copper alloy backplane assembly on the heating table, place an indium block within the welding surface of the backplane assembly, and the welding area is 250cm 2 , the amount of metal indium applied is 5g, the copper alloy backplane is heated to 170°C, and after the indium block is melted, the metal indium is infiltrated onto the surface of the backplane component by using an ultrasonic back-indium equipment.

[0028] Subsequently, use a scraper to scrape the metal indium...

Embodiment 2

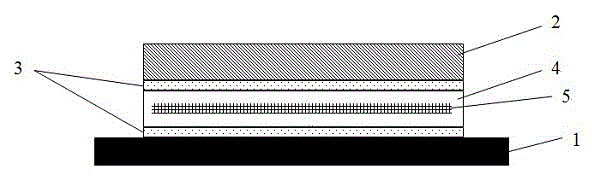

[0032] This embodiment provides a sputtering target, such as figure 2 shown. The backplane component 1 is a copper alloy material, on which a metal indium layer 3 is applied. A conductive adhesive layer 4 is stacked on the metal indium layer, and a non-magnetic metal mesh 5 is arranged in the conductive adhesive layer 4. The non-magnetic metal mesh 5 adopts a copper mesh, and a target material 2 is bonded to the conductive adhesive layer. A layer of metal indium layer 3 is applied on the soldering surface.

[0033] The binding method is carried out according to the following steps: the binding method includes the following steps: first, place the copper alloy backplane assembly on the heating table, place an indium block within the welding surface range of the backplane assembly, and the welding area is 250cm 2 , the amount of metal indium applied is 12.5g, the copper alloy backplane is heated to 190°C, and after the metal indium block is melted, the metal indium is infiltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com