Comprehensive treatment method of shale gas extraction water

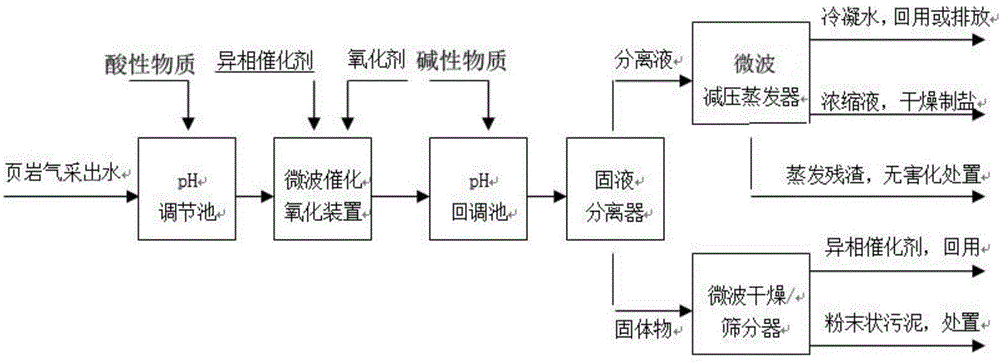

A treatment method and shale technology, applied in the field of formation produced water treatment, can solve problems such as being unsuitable for single-well small water volume wastewater treatment, difficult to survive high-chlorine wastewater, and produced water reinjection restrictions, etc., and achieve catalytic activity that can be reused , high environmental protection and economic benefits, low microwave source loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The treatment process of produced water is as follows:

[0054] a. Add hydrochloric acid to the produced water to adjust its pH value to 3.5. After stirring and mixing, it is placed in a microwave catalytic oxidation device, and then the catalyst iron pillared bentonite is added. The addition is 5% of the total weight of the produced water. The amount of hydrogen oxide is 1% of the total weight of the produced water, stir evenly, turn on the microwave catalytic oxidation device, and make the produced water react under the power of 400 watts for 10 minutes.

[0055] b. Export the reaction solution obtained in a to the pH callback pool, add sodium hydroxide to adjust the pH value of the reaction solution to 8.5, produce coagulation after stirring, and use a cyclone centrifugal separator to separate the solid and liquid to obtain the separation liquid And solid matter, the catalyst separated from the solid matter can be reused 3-8 times.

[0056] c. Import the separated l...

Embodiment 2

[0059] The treatment process of produced water is as follows:

[0060] a, add hydrochloric acid to the produced water to adjust its pH value to 4.5, place it in the microwave catalytic oxidation device after stirring and mixing, then add catalyst zinc pillared bentonite, the addition is 6% of the total weight of produced water, add over The amount of hydrogen oxide is 2% of the total weight of the produced water, stir evenly, turn on the microwave catalytic oxidation device, and make the produced water react for 30 minutes at a power of 500 watts.

[0061] b. Export the reaction solution obtained in a to the pH callback tank, add sodium hydroxide to adjust the pH value of the reaction solution to 11, produce coagulation after stirring, and use a cyclone centrifugal separator to separate the solid and liquid to obtain the separation liquid And solid matter, the catalyst separated from the solid matter can be reused.

[0062] c. Import the separated liquid obtained in b into a ...

Embodiment 3

[0065] The treatment process of produced water is as follows:

[0066] a. Add hydrochloric acid to the produced water to adjust its pH value to 2, place it in a microwave catalytic oxidation device after stirring and mixing, then add catalyst iron pillared bentonite, the addition is 4.5% of the total weight of produced water, add over The amount of hydrogen oxide is 0.5% of the total weight of the produced water, stir evenly, turn on the microwave catalytic oxidation device, and make the produced water react for 3 minutes at a power of 300 watts.

[0067] b. Export the reaction solution obtained in a to the pH callback pool, add calcium hydroxide to adjust the pH value of the reaction solution to 7.5, produce coagulation after stirring, and use a cyclone centrifugal separator to separate the solid and liquid to obtain the separation liquid And solid matter, the catalyst separated from the solid matter can be reused.

[0068] c. Import the separated liquid obtained in b into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com