An inorganic all-solid-state electrochromic device and its preparation method

An electrochromic device and electrochromic layer technology, applied in instruments, ion implantation plating, coating, etc., can solve the problems of increased response time, unfavorable rapid discoloration, performance degradation, etc., to extend service life and shorten discoloration Response time, the effect of reducing residual charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

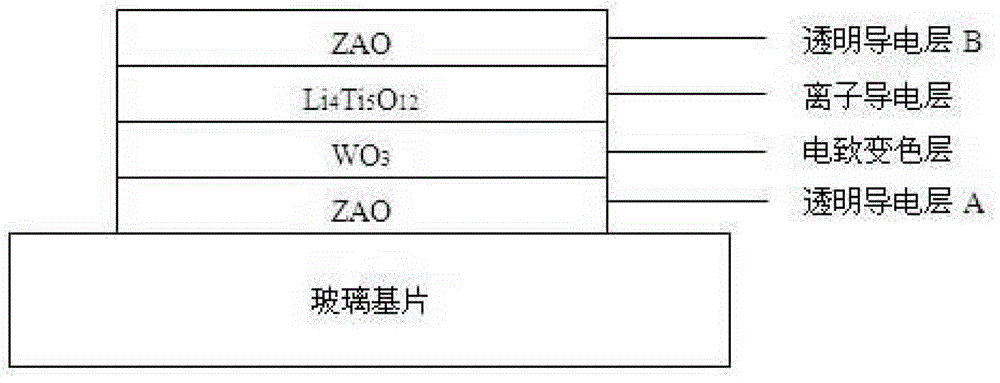

[0021] Preparation with ZAO / WO 3 / Li 4 Ti 5 o 12 Inorganic all-solid-state electrochromic devices with / ZAO structure and film thicknesses of 800nm / 500nm / 250nm / 800nm in sequence.

[0022] (1) Wash a 2×3cm glass substrate in acetone, absolute ethanol and deionized water in sequence, and place it in a vacuum magnetron sputtering system after drying, and vacuumize to 2×10 -6 Pa.

[0023] (2) Pre-sputtering (burning target) for 20 minutes, using the following parameters to prepare a ZAO film on a glass substrate:

[0024] Target material: sintered body of zinc oxide and alumina (mass fraction of alumina 5%)

[0025] Sputtering type: DC sputtering

[0026] Target base distance: 8cm

[0027] Deposition pressure: 0.5Pa

[0028] Sputtering power: 400W

[0029] Film thickness: 800nm

[0030] (3) Pre-sputtering (burning target) for 20 minutes, using the following parameters to prepare WO on the ZAO film 3 film:

[0031] Target material: metal tungsten

[0032] Sputtering ...

Embodiment 2

[0049] Preparation with ZAO / WO 3 / Li 4 Ti 5 o 12 Inorganic all-solid-state electrochromic devices with / ZAO structure and film thicknesses of 600nm / 400nm / 250nm / 600nm in sequence.

[0050] (1) Wash a 2×3cm glass substrate in acetone, absolute ethanol and deionized water in sequence, and place it in a vacuum magnetron sputtering system after drying, and vacuumize to 2×10 -6 Pa.

[0051] (2) Pre-sputtering (burning target) for 20 minutes, using the following parameters to prepare a ZAO film on a glass substrate:

[0052] Target material: sintered body of zinc oxide and alumina (mass fraction of alumina 5%)

[0053] Sputtering type: DC sputtering

[0054] Target base distance: 8cm

[0055] Deposition pressure: 0.5Pa

[0056] Sputtering power: 300W

[0057] Film thickness: 600nm

[0058] (3) Pre-sputtering (burning target) for 20 minutes, using the following parameters to prepare WO on the ZAO film 3 film:

[0059] Target material: metal tungsten

[0060] Sputtering ty...

Embodiment 3

[0077] Preparation with ZAO / WO 3 / Li 4 Ti 5 o 12 Inorganic all-solid-state electrochromic devices with / ZAO structure and film thicknesses of 700nm / 600nm / 250nm / 700nm in sequence.

[0078] (1) Wash a 2×3cm glass substrate in acetone, absolute ethanol and deionized water in sequence, and place it in a vacuum magnetron sputtering system after drying, and vacuumize to 2×10 -6 Pa.

[0079] (2) Pre-sputtering (burning target) for 20 minutes, using the following parameters to prepare a ZAO film on a glass substrate:

[0080] Target material: sintered body of zinc oxide and alumina (mass fraction of alumina 5%)

[0081] Sputtering type: DC sputtering

[0082] Target base distance: 8cm

[0083] Deposition pressure: 0.5Pa

[0084] Sputtering power: 350W

[0085] Film thickness: 700nm

[0086] (3) Pre-sputtering (burning target) for 20 minutes, using the following parameters to prepare WO on the ZAO film 3 film:

[0087] Target material: metal tungsten

[0088] Sputtering ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com