Method and device for burning petroleum coke by use of circulating fluid bed

A technology of circulating fluidized bed and petroleum coke, applied in the field of circulating fluidized bed, can solve problems such as difficulty in ignition, formation of slag, difficulty in ignition and burnout, etc., and achieve the effect of effective control and reduction of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

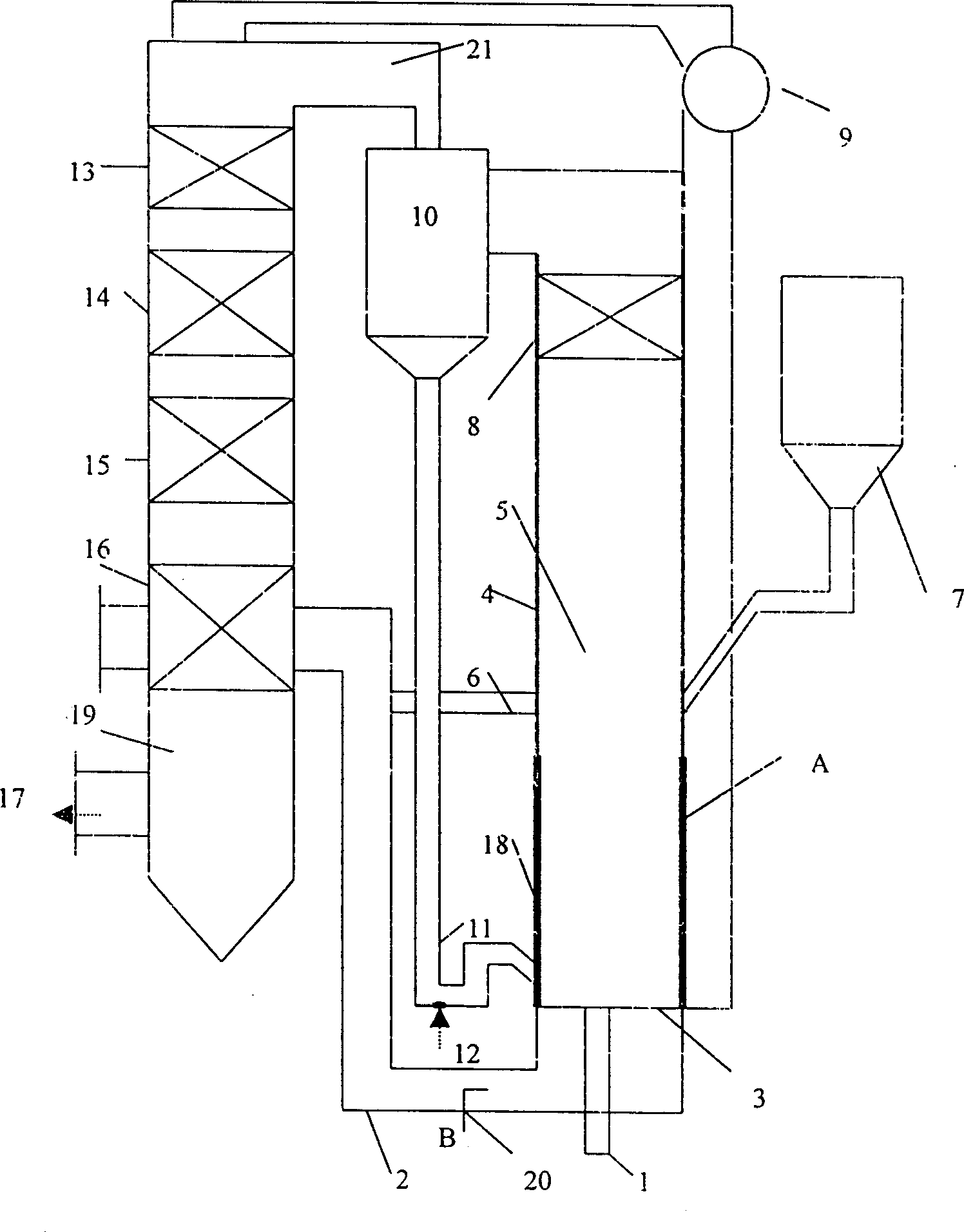

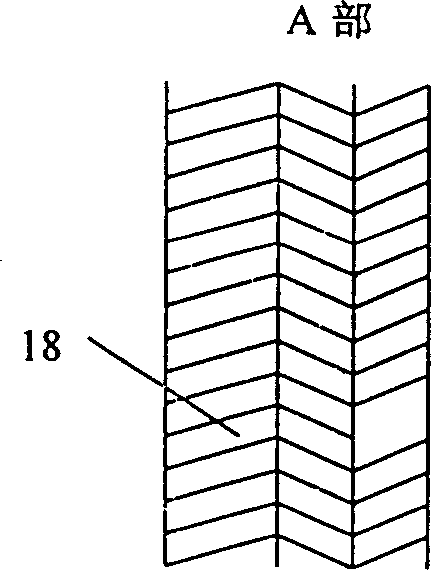

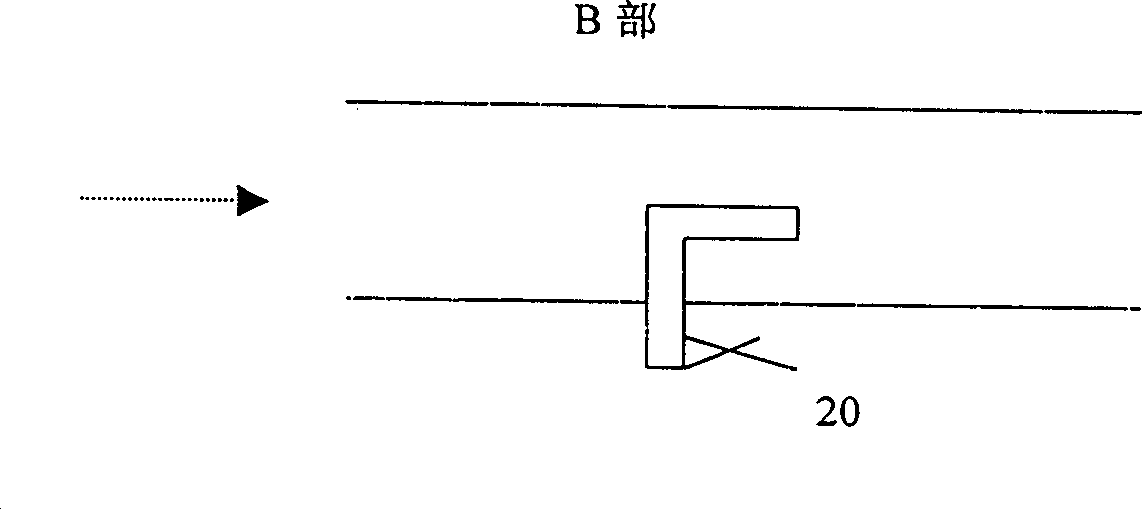

[0018] like figure 1 As shown, a circulating fluidized bed utilizing the present invention is mainly composed of a cold slag pipe 1, a primary air duct 2, an air distribution plate 3, a membrane water wall 4, a combustion chamber 5, a secondary air duct 6, and a silo 7. Secondary superheater 8, steam drum 9, cyclone separator 10, feeder 11, third-stage superheater 13, primary superheater 8, air preheater 16, tail flue 19 and pipeline oil burner 20 constitute. The silo 7 for adding mixed fuel communicates with the combustion chamber 5, the bottom of the combustion chamber 5 is equipped with an air distribution plate 3, the inner wall of the upper part of the combustion chamber 5 is a membrane water wall 4, and the lower part is arranged with a thermal insulation and anti-wear layer 18, which is heat-resistant The wall height of the wear-resistant layer 18 accounts for 1 / 5 of the total height of the combustion chamber wall, such as figure 2 shown. The air duct is composed of...

Embodiment 2

[0023] Keep the structure of the circulating fluidized bed in Example 1 unchanged, only change the height of the heat preservation and wear-resistant layer 18, so that the height of the heat preservation and wear-resistant layer 18 accounts for 1 / 6 of the total height of the wall surface of the combustion chamber 5 . Used petroleum coke mixed fuel can also adopt following proportioning; Coal accounts for 15% of the gross weight of two kinds of fuels of coal and petroleum coke, and the addition of desulfurizer limestone makes the mol ratio of Ca / s in the mixed mixed fuel after mixing be 1.3, while the particle size parameters in the mixed fuel are the same as in Example 1. Adopt the same method as embodiment 1, only the air supply volume is different in the staged combustion process, the primary air supply volume accounts for 65%, and the secondary air supply volume accounts for 35%, can reach the effect of embodiment 1 equally, make the desulfurization rate reach 90% %, reduce...

Embodiment 3

[0025] like figure 1 In the circulating fluidized bed, only the height of the thermal insulation and wear-resistant layer 18 is changed under the condition of keeping other structures unchanged, so that the height of the thermal insulation and wear-resistant layer 18 accounts for 1 / 5 of the total height of the combustion chamber 5 walls. Adopt same method and following mixed fuel, coal accounts for 20% of the gross weight of two kinds of fuels of coal and petroleum coke, and the addition amount of desulfurizer limestone makes the mol ratio of Ca / s in the mixed fuel after mixing be 1.5; In the fluidized bed staged combustion process, the primary air supply volume accounts for 70%, and the secondary air supply volume accounts for 30%. Under the condition that other parameters remain unchanged, the same effect as that of Example 1 can be achieved, and NOx emissions can be reduced. The desulfurization rate reaches 92%, eliminates the phenomenon of slag formation, is beneficial to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com