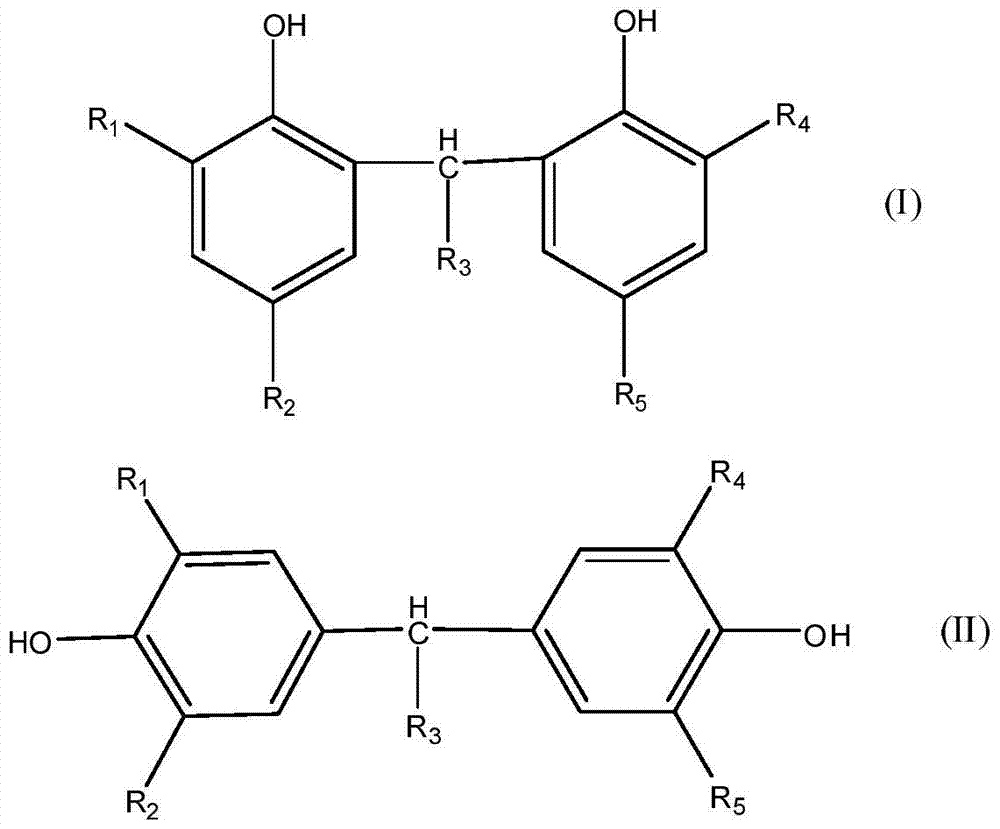

Preparation method and application of bisphenol antioxidant based on mixed base catalyst catalysis

A technology of catalyst and mixed alkali, which is applied in the field of antioxidant products and its preparation, can solve problems such as unfavorable industrial production, harsh reaction conditions, and complicated post-processing, and achieve scientific and reasonable route design, short reaction cycle, and reduced pollutant discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

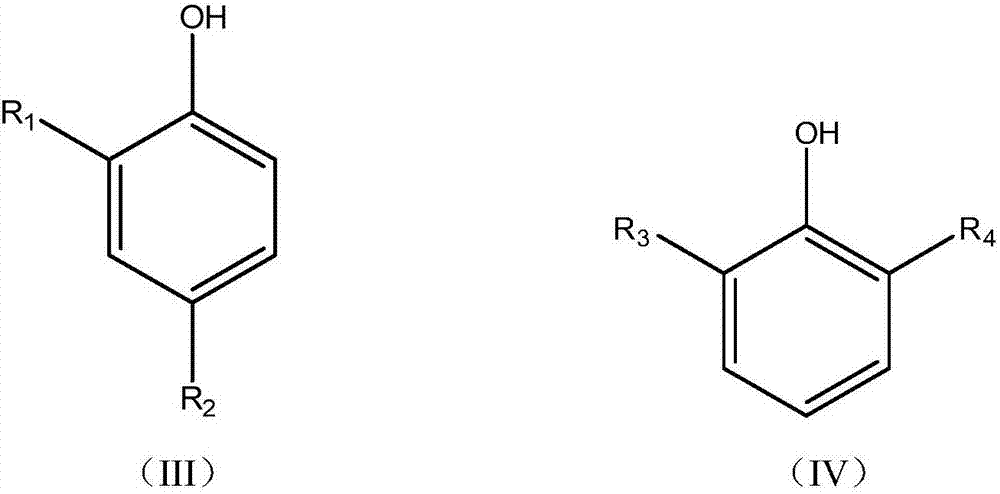

Method used

Image

Examples

preparation example Construction

[0046] In the preparation method of the present invention, the reaction is carried out in a closed reactor, and the reaction system carries out the condensation reaction in a closed state, which can effectively avoid the oxidation of the alkylphenol raw material and the aldehyde compound and the oxidation of the bisphenol compound product, The finally obtained bisphenol compound product is off-white crystal.

[0047] A typical application of the bisphenol compound antioxidant of the present invention is as an additive in lubricating oil compositions, but it can also be used in other applications. Further, some embodiments of the present invention disclose a lubricating oil composition, which contains the bisphenol compound antioxidant, and may also include one or more of the following components, such as lubricating Oil base stock, detergent and dispersant, antiwear agent, zinc dialkyldithiophosphate, alkylated diphenylamine, viscosity index improver, pour point depressant, co...

Embodiment 1

[0051] Add 14.63g of paraformaldehyde, 20g of 2-tert-butyl p-cresol (4:1 molar ratio), 1.92g of mixed base catalyst sodium tetramethoxyborate and 360ml of dimethyl sulfoxide (DMSO) into the belt In a thick-walled pressure-resistant glass bottle with magnets, set the temperature to 150° C., raise the temperature to the set temperature, and stir for 0.5 hours to react. After the reaction, add any one of the aforementioned organic acids (such as acetic acid) to the flask for neutralization, after adding deionized water, the product precipitates, and the product 2,2'-methylene-bis(4-methyl- 6-tert-butylphenol). The product yield is greater than 95%, and the product purity is greater than 98%.

Embodiment 2

[0053] Add 23.2g of paraformaldehyde, 25.5g of 2-tert-butyl-p-cresol (5:1 molar ratio), 1.10g of mixed base catalyst lithium tetramethoxyborate and 310ml of DMSO into the thick-walled In a pressure-resistant glass bottle, the set temperature is 100° C., the temperature is raised to the set temperature, and the reaction is stirred for 2 hours. After the reaction finishes, the aftertreatment of the reaction product is the same as in Example 1. The product yield is greater than 95%, and the product purity is greater than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com