Lithium ion battery module safety protection system

A technology for lithium-ion batteries and battery modules, which is used in safety/protection circuits, secondary battery repair/maintenance, battery disconnect circuits, etc. Electromagnetic interference and other problems, to achieve the effect of light structure, delaying risk occurrence, providing escape and emergency disposal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

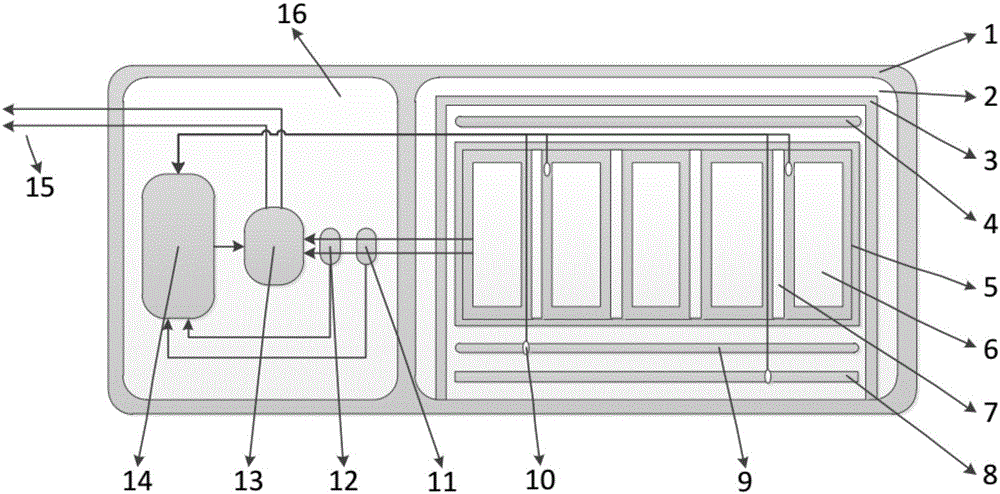

[0027] like figure 1 As shown, the lithium-ion battery module includes: battery module casing 1, gas-resistant bag 2, plastic fastener 3, deformable heat-conducting pad 4, heat-conducting member 5, lithium-ion soft-packed single cell 6, and electrostatic isolation pad 7 , heat dissipation plate 8, deformation heat conduction pad 9, temperature sensor 10, current sensor 11, voltage sensor 12, electronic switch 13, MCU14, power output terminal 15, battery management system circuit board 16.

[0028] Specifically, the lithium-ion soft-packed single battery cell 6 of this embodiment can be a liquid lithium-ion battery cell packaged in aluminum-plastic film, or a solid-state lithium-ion battery cell packaged in aluminum-plastic film, or a gel cell packaged in aluminum-plastic film. state lithium-ion batteries, which is not limited in this embodiment. like figure 1 As shown, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com