A Flow Field Uniform Device Based on Shrinkage Curve Design

A shrinking curve and curve technology, applied in the field of vibration and noise control of liquid-filled pipelines, can solve problems such as increased shaft frequency and blade frequency noise, poor effect, and distortion of the velocity field at the inlet of the flow channel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

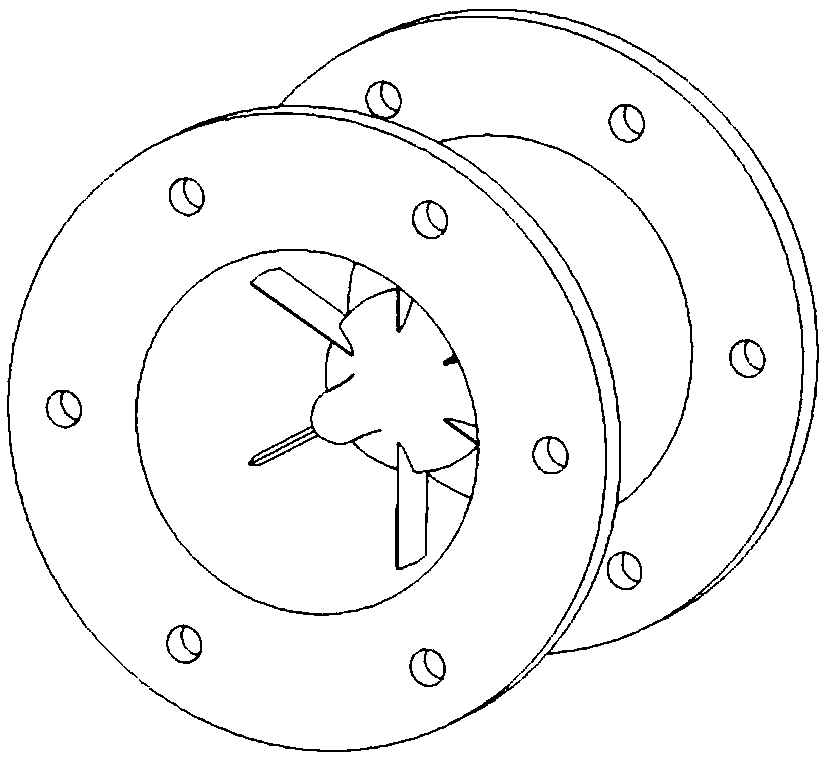

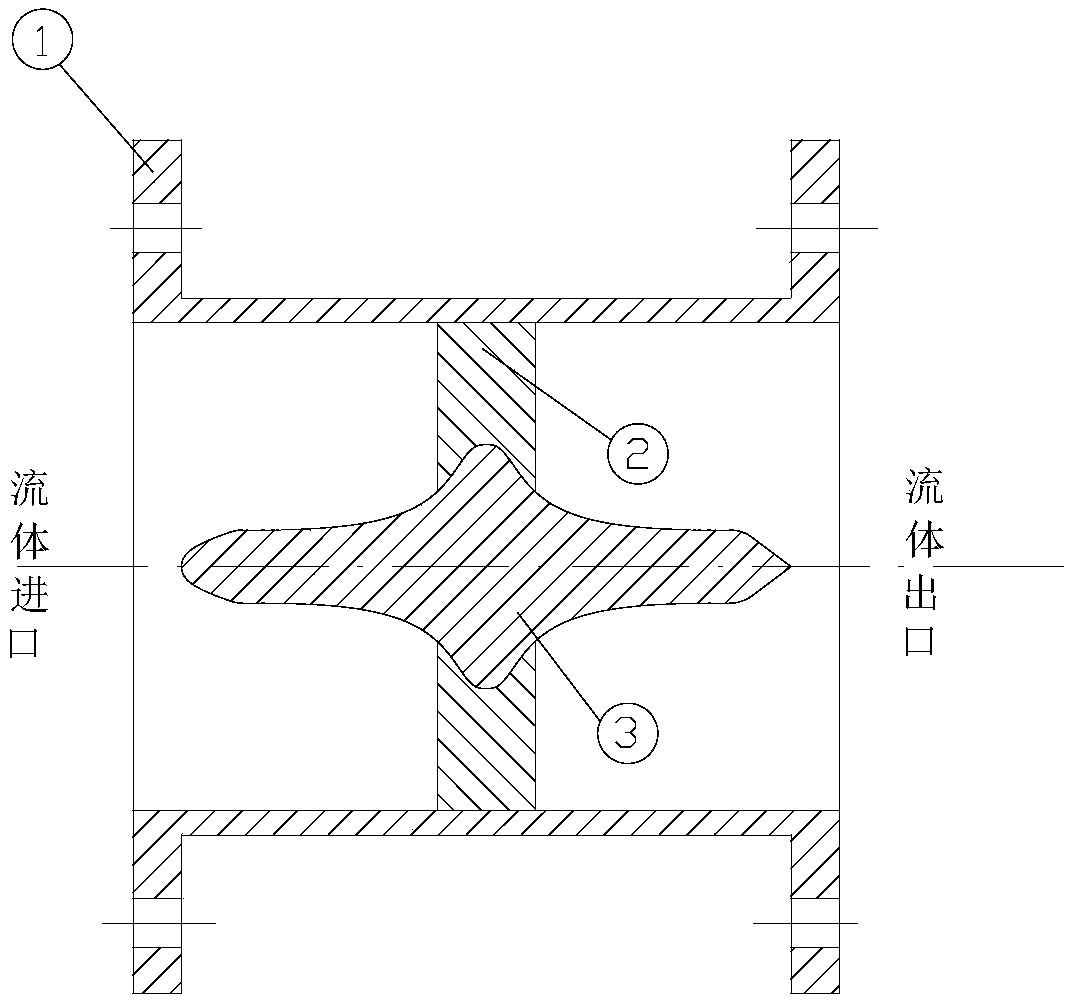

[0020] A flow field uniform device designed based on a contraction curve, the flow field uniform device includes a sleeve 1, a blade 2 and a curved contraction body 3;

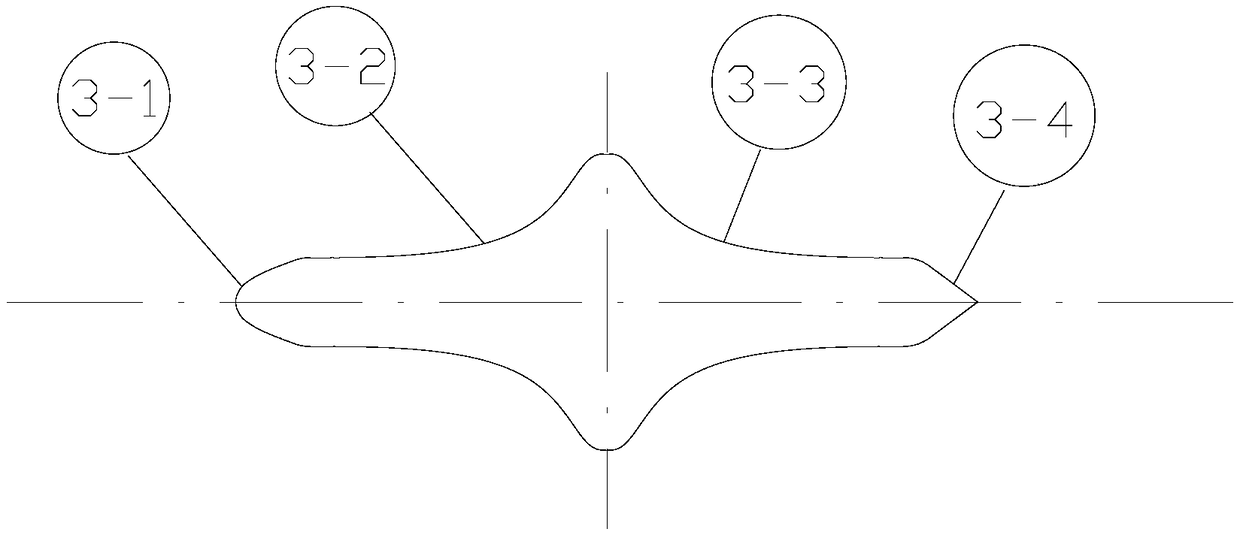

[0021] The blade 2 is designed as a symmetrical NACA blade shape with equal thickness; the curved constriction body 3 is divided into a front diversion section 3-1, a front constriction section 3-2, a rear constriction section 3-3 and a rear diversion section 3- 4 four parts; the shape of the front diversion section 3-1 is blade-shaped, and the shape of the rear diversion section 3-4 is linear; the material of the casing 1, the blade 2 and the curved shrinkage body 3 is stainless steel; the front shrinkage section 3 The profile line of -2 and the profile line of the rear contraction section 3-3 are axisymmetric and are optimized bicubic curves;

[0022] The curved contraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com