Recovery method of protein in high concentration protein wastewater

A protein wastewater and recovery method technology, applied in the field of protein separation, can solve the problems of low treatment cost, high protein removal rate, low protein removal rate, etc., and achieve the effect of strong precise adjustment ability, high product added value, and improved removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

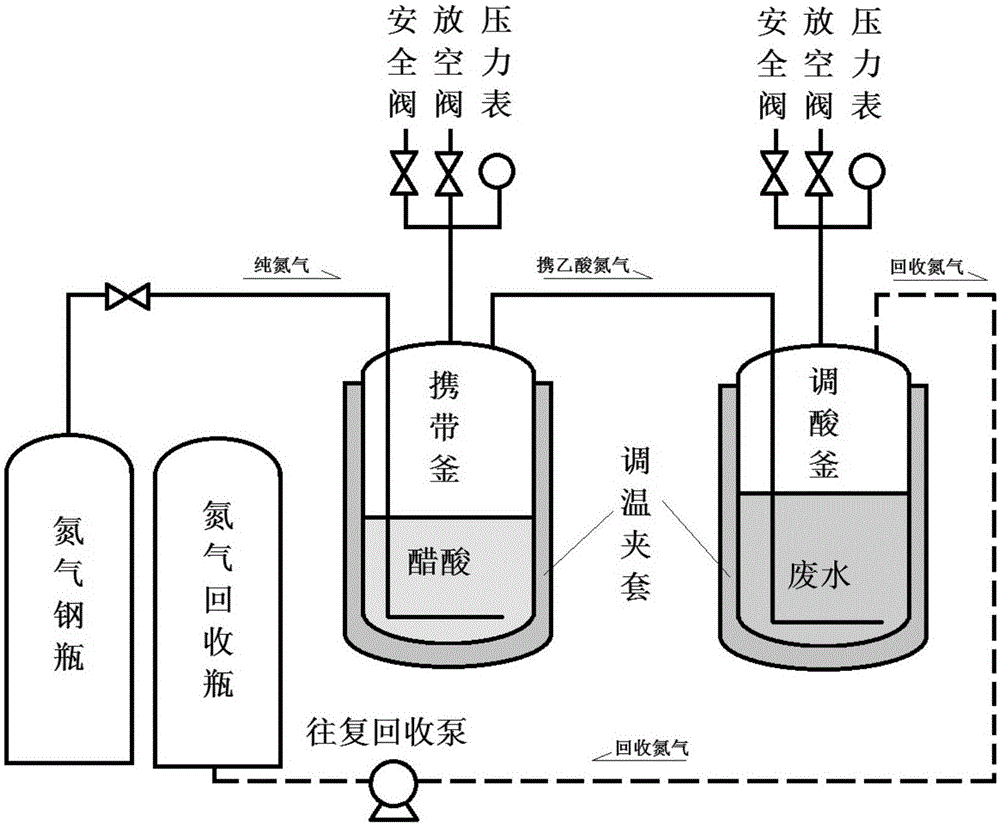

Method used

Image

Examples

Embodiment 1

[0040] Select a kind of waste water produced after pollock surimi processing. The initial pH value of the surimi wastewater is about 7.1. According to the analysis of protein components, the protein concentration of the waste water after centrifugation pretreatment is 8.9±0.8mg / mL, and the isoelectric point Relatively densely concentrated in the vicinity of 5.5 and 4.3, according to the analysis results, it is divided into two levels according to the isoelectric point of the protein from large to small.

[0041] First-level isoelectric precipitation, the nitrogen pressure of the carrying tank is maintained at 0.5MPa, the temperature of the carrying tank is 50°C, and the acid-adjusting tank is kept at room temperature. When the cycle carrying time is 30 minutes, the pH of the acid-adjusting tank reaches around 5.5. After the gas in the acid adjustment tank was emptied, let it stand for precipitation for 20 minutes, and then centrifuge the high-concentration protein wastewater to...

Embodiment 2

[0044] Select a kind of wastewater produced after the processing of blue cod surimi. The initial pH value of the surimi wastewater is about 7.1. According to the analysis of protein components, the protein concentration of the wastewater after centrifugation pretreatment is 8.5±1.1mg / mL, and the isoelectric point They are respectively concentrated in the vicinity of 6.0 (there are three bands of 6.6, 6.3, and 5.8) and 4.3 (two bands of 4.4 and 4.2). According to the analysis results, the isoelectric point of the protein is adjusted from large to small by using a precise fractional precipitation scheme. It is determined to be divided into 5 levels, namely: 6.6, 6.3, 5.8, 4.4 and 4.2.

[0045] For first-stage isoelectric precipitation, the nitrogen pressure of the carrying tank is kept at 1.0MPa, the temperature of the carrying tank is 25°C, and the acid-adjusting tank is kept at normal temperature. When the cycle carrying time is 15 minutes, the pH of the acid-adjusting tank rea...

Embodiment 3

[0051] Select a kind of wastewater produced after processing blue cod surimi. The initial pH value of the surimi wastewater is about 7.1. According to the analysis of protein components, the protein concentration of the wastewater after centrifugation pretreatment is 8.5±1mg / mL, and the isoelectric points are respectively Concentrate around 6.0 (there are three bands of 6.6, 6.3, and 5.8) and 4.3 (two bands of 4.4 and 4.2). According to the analysis results, the isoelectric point of the protein is determined from the largest to the smallest by using a quick fractional precipitation scheme Divided into 3 levels, namely: 6.5, 5.8 and 4.3.

[0052] For first-stage isoelectric precipitation, the nitrogen pressure of the carrying tank is maintained at 1.0 MPa, the temperature of the carrying tank is 30°C, the acid-adjusting tank is kept at room temperature, and the pH of the acid-adjusting tank reaches 6.5 when the cycle carrying time is 30 minutes. After the acid-adjusting tank wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com