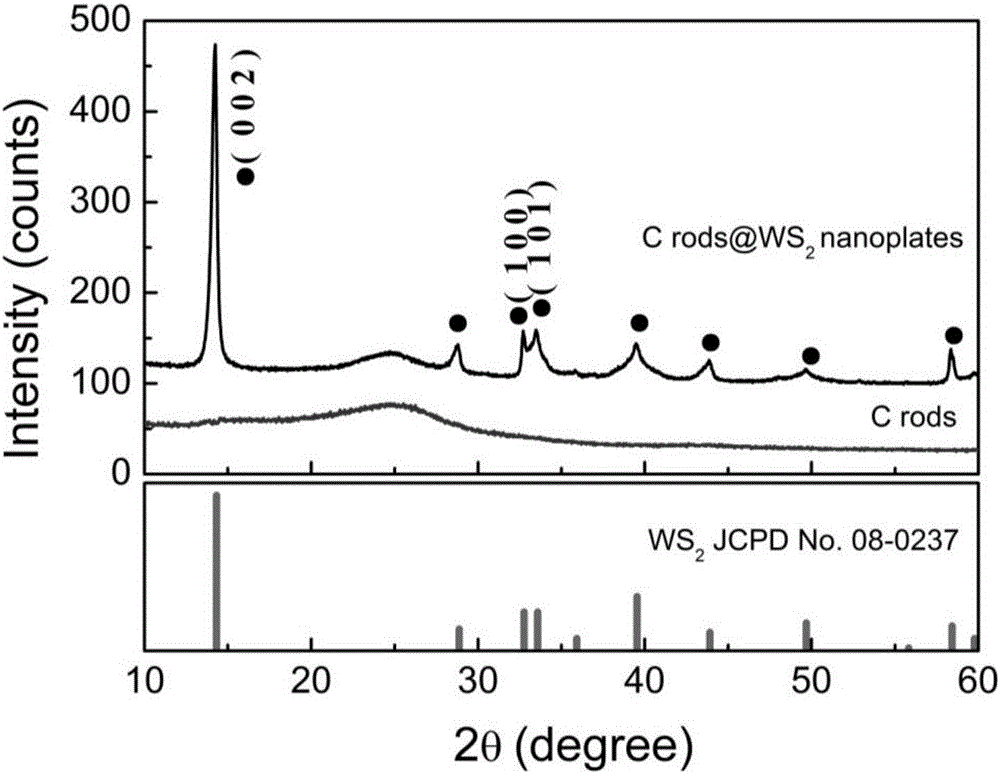

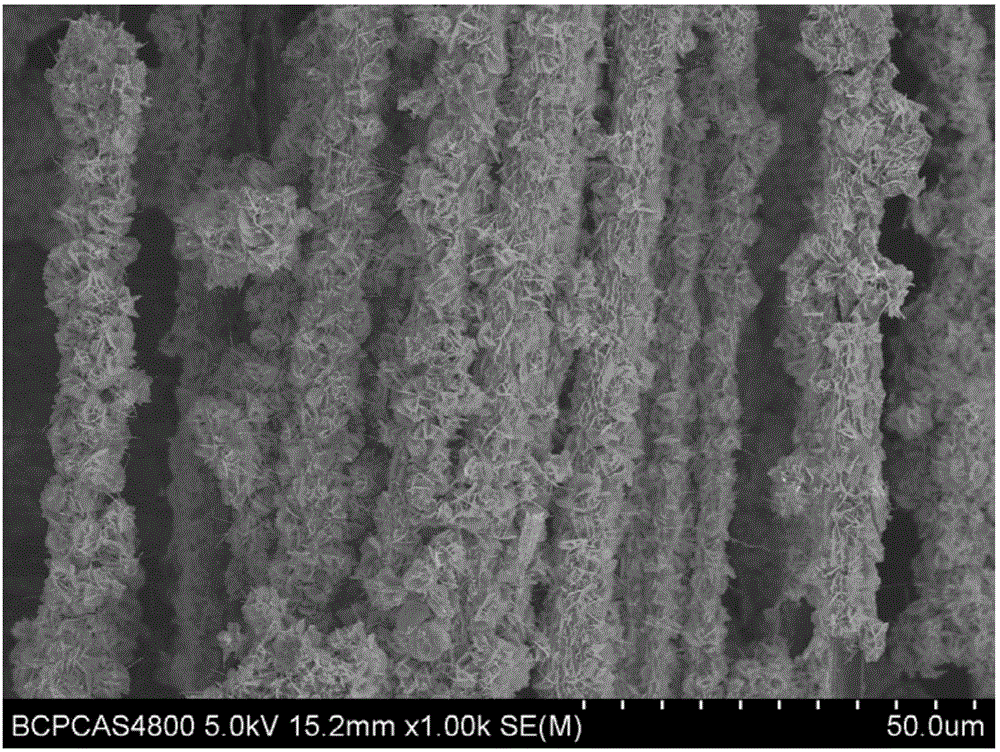

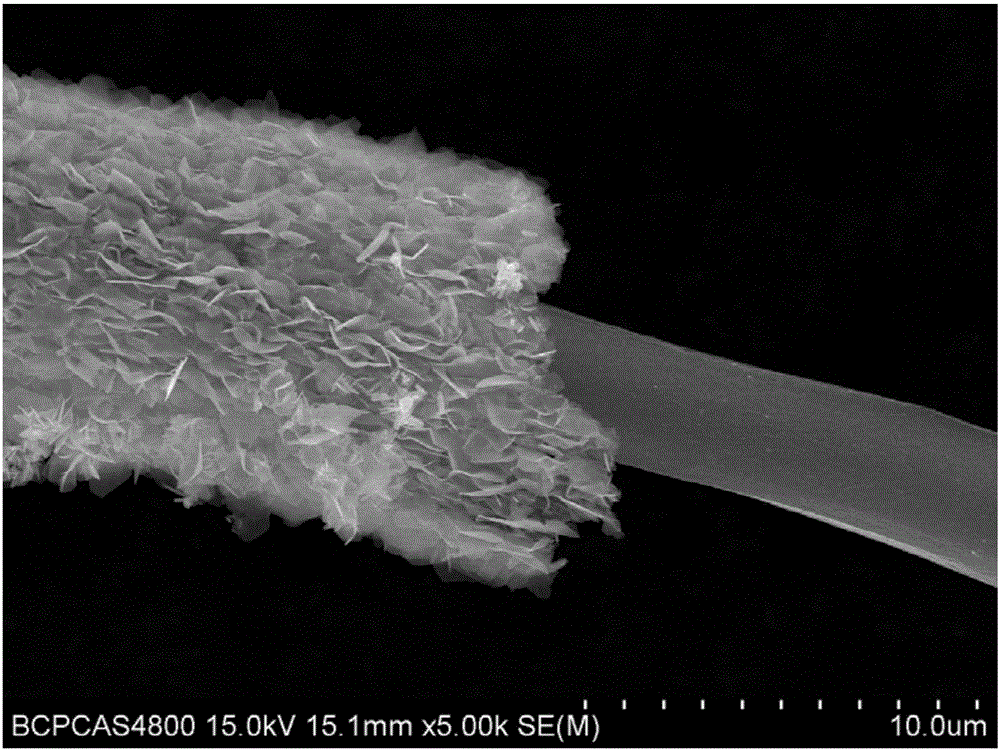

Carbon fiber@ tungsten disulfide nanosheet kernel-shell composite structure and preparation method thereof

A technology of tungsten disulfide and composite structure, applied in chemical instruments and methods, nanotechnology, tungsten compounds, etc., can solve problems such as difficult control, complex chemical reactions, complex purification and impurity removal, etc., and achieve uniform diameter and thickness and high purity , nanoscale ordered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the carbon fiber@tungsten disulfide nanosheet core-shell composite structure proposed by the present invention includes the following steps and contents:

[0031] (1) Using commercially available analytically pure sulfur powder, WO 3 Powder and chemically pure pre-oxidized polyacrylonitrile fibers are used as raw materials.

[0032] (2) will WO 3 Powder and absolute ethanol are mixed according to the ratio of (10-100g): (50-100ml), fully stirred to make a uniform suspension; then place the pre-oxidized polyacrylonitrile fiber in it and soak for 10-60min; then dry Dry and set aside.

[0033](3) In the vacuum tube furnace, place the alumina ceramic crucible with sulfur powder on the top of the air flow at a distance of 10-40 cm from the central heating area of the furnace, and place the crucible soaked in WO 3 A quartz-based boat of suspension of pre-oxidized polyacrylonitrile fibers is placed in the central heating zone of the furnace.

[...

Embodiment 1

[0039] Example 1: In a vacuum tube furnace, place an alumina ceramic crucible with 1g of sulfur powder on the top of the airflow at a distance of 20cm from the central heating zone of the furnace, and fill it with a concentration of 4g of WO 3 Powder and 5ml of absolute ethanol suspension prepared and dried pre-oxidized polyacrylonitrile fiber quartz-based boat placed in the central heating area of the furnace.

[0040] Before heating, first use a vacuum pump to evacuate the entire system to below 0.02Pa, then feed high-purity argon gas with a volume above 99.99vol.% into the system, and repeat 3 times to remove the air in the system. Then the temperature was raised to 400° C. at a rate of 20° C. / min, kept for 10 minutes, and then raised to 1050° C. at a rate of 30° C. / min, and kept for 1 hour. During the heating process, under the premise that the vacuum system continued to work, argon gas was introduced and the flow rate of the carrier gas was kept at 100 standard cubic ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com