Method for preparing nano zinc oxide by using liquid diaphragm discharge plasma

A liquid-phase diaphragm discharge and nano-zinc oxide technology, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the complex preparation process of nano-scale zinc oxide, harsh conditions, Environmental pollution and other issues, to achieve the effect of low cost, mild conditions, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Treatment of cathode and anode zinc sheets: Take a high-purity zinc sheet of 4 mm×15 mm×1 mm, grind and polish it with water sandpaper, and then ultrasonically clean it in acetone for 10 min, and then wash it in 0.3 mol / L NaOH aqueous solution Soak for 30 minutes, then wash with distilled water to remove grease and other organic pollutants on the surface of the zinc sheet.

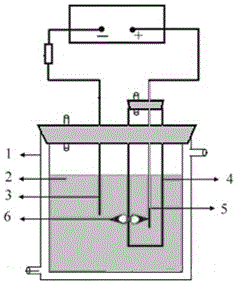

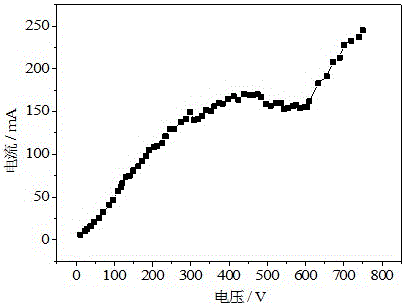

[0039] (2) Liquid-phase diaphragm discharge plasma device: Take 250 mL temperature-controllable reactor 1, add 150 mL 2g / L sodium sulfate solution as electrolyte 2; insert a 4 mm×15 mm×1 mm cathode into the electrolyte A zinc sheet 3 and a quartz tube 4 with a diameter of 1.5 cm; the anode zinc sheet 5 treated above is placed in the quartz tube 4; a small hole 6 with a diameter of 0.5 mm is opened at a distance of 1 cm from the bottom of the quartz test tube to electrolyze the anode and cathode The liquid is connected through the small hole 6; the depth of the cathode and anode inserted into the...

Embodiment 2

[0042] (1) Treatment of cathode and anode zinc sheets: the size of cathode and anode zinc sheets is 5 mm×15 mm×1 mm, and the treatment method is the same as in Example 1.

[0043] (2) Liquid-phase diaphragm discharge plasma device: the same as in Embodiment 1.

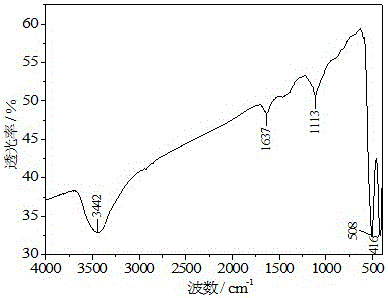

[0044] (3) Preparation of nano-zinc oxide: control the voltage between the two electrodes to 650 V, and the current to 110 mA to generate glow in the small hole to form a stable glow discharge plasma; during the discharge process, the anode zinc sheet is continuously consumed, The solution turned milky white. For the uniformity of the solution, the solution was continuously stirred at 110 r / min. After continuous discharge for 2 hours, a white zinc oxide turbid liquid was obtained; after ultrasonic dispersion for 30 minutes, it was centrifuged at a speed of 10,000 r / min, and the product was washed several times with distilled water to remove the electrolyte sodium sulfate, then washed several times with absolute ethano...

Embodiment 3

[0046] (1) Treatment of cathode and anode zinc sheets: the size of cathode and anode zinc sheets is 6 mm×15 mm×1 mm, and the treatment method is the same as that in Example 1.

[0047] (2) Liquid-phase discharge plasma device: same as that of Embodiment 1.

[0048] (3) Preparation of nano-zinc oxide: Control the voltage between the two electrodes to 700 V and the current to 130 mA to generate glow in the small hole and form a stable glow discharge plasma; during the discharge process, the anode zinc sheet is continuously consumed, The solution turned milky white. For the uniformity of the solution, the solution was continuously stirred at 130 r / min. After continuous discharge for 2 hours, a white zinc oxide turbid liquid was obtained; after ultrasonic dispersion for 30 minutes, it was centrifuged at a speed of 10,000 r / min, and the product was washed several times with distilled water to remove the electrolyte sodium sulfate, then washed several times with absolute ethanol, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com