Hierarchical opening and closing mode low pressure casting machine

A low-pressure casting machine, mold opening and closing technology, applied in the field of casting equipment, can solve the problems of casting deformation, small processing range, large shrinkage, etc., and achieve the effects of preventing casting breakage, convenient and flexible operation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

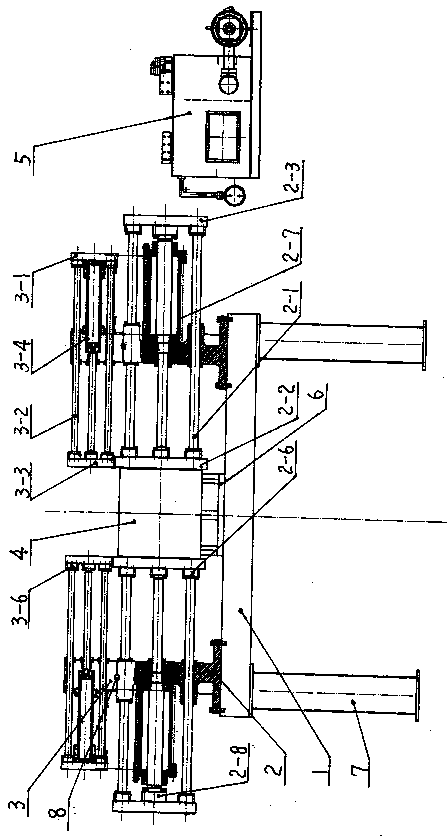

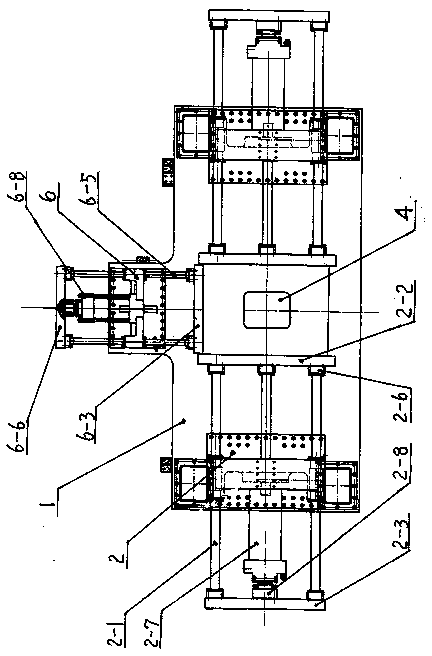

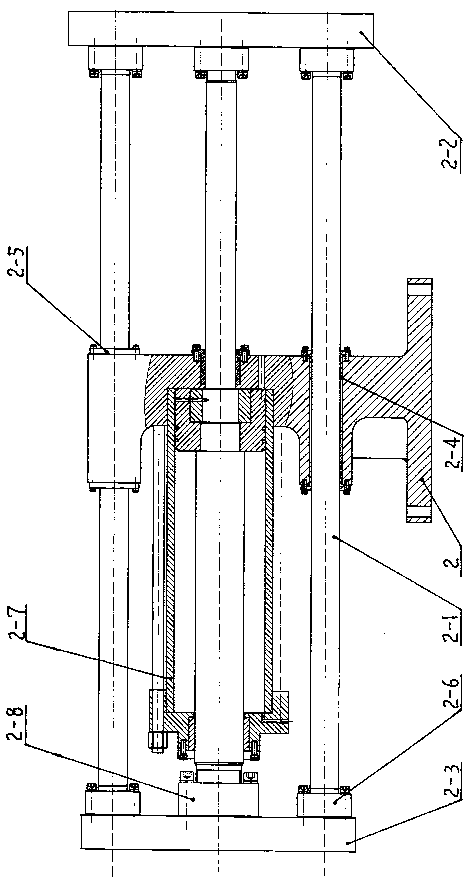

[0013] Examples, see attached Figure 1~5 The low-pressure casting machine in the hierarchical opening and closing mode is to fix the workbench 1 above the four brackets 7. The workbench 1 is in a T shape, and the left and right ends of the workbench 1 are symmetrically fixed with a first-level opening of the same structure. Clamping support seat 2. The first-level mold opening and closing guide bar cover 2-4 is equipped with a first-level opening and closing mold guide bar 2-1 on the upper and lower level in the first-level opening and closing mold support seat 2, and the first-level opening and closing mold guide bar cover 2-4 Fix the first-level opening and closing mold guide bar sleeve gland 2-5 with screws on the left and right ends of the mold. In the first-level mold-opening support seat 2 in the middle of the upper and lower-level mold-closing guide lever sleeves 2-4, the left side is equipped with a mold-closing oil cylinder 2-7 for the mold-closing stage 2-7, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com