Preparation method and application of nitrogen and phosphorus co-doped porous carbon materials

A technology of co-doping and carbon materials, applied in chemical instruments and methods, catalyst supports, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Mix trimethylolpropane, urea and phosphoric acid in a mass ratio of 1:0.1:0.1 as a carbonization precursor, add carbonization activator anhydrous ferric chloride (0.01% of the total mass of carbonization precursor) and grind twelve After 1 hour, conduct a carbonization treatment under nitrogen for 0.5 hours (carbonization temperature is 300 °C, heating rate is 1 °C / min), then soak in 0.1 M nitric acid for 12 hours, and then put it into a ball mill for full grinding Twelve hours, after suction filtration and water washing, put it into a vacuum oven and dry for 10 hours to obtain a non-metallic catalyst composed of nitrogen and phosphorus as a porous carbon material.

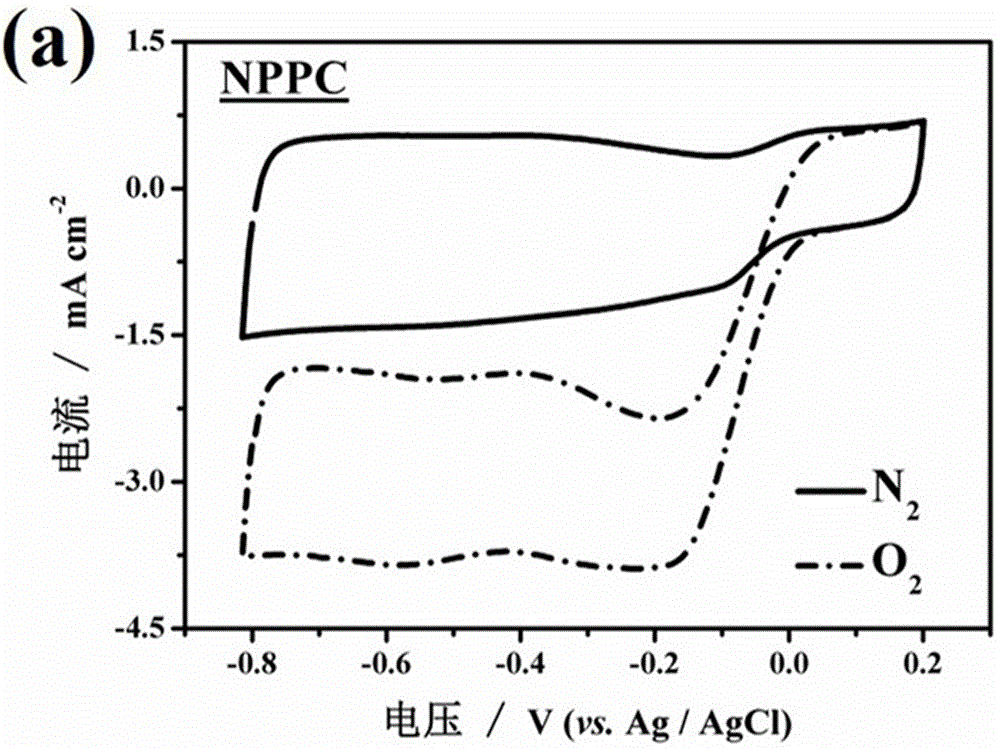

[0036] The half-point position of the nitrogen-phosphorous co-doped porous carbon material non-metallic catalyst with the addition of 0.01% carbonization activator was negatively shifted by 15 mV compared with the commercial platinum-carbon catalyst.

Embodiment 2

[0038] Mix pentaerythritol, melamine and red phosphorus in a mass ratio of 1:0.5:2 as a carbonization precursor, add a carbonization activator cobalt chloride (0.1% of the total mass of the carbonization precursor) and grind for twelve hours. Under the second carbonization treatment. First carbonization treatment for 1 hour (carbonization temperature is 400 °C, heating rate 5 °C / min), second carbonization treatment for 1 hour (carbonization temperature is 800 °C, heating rate 5 °C / min), and then soaked in 0.5 M sulfuric acid After being treated for 10 hours, put it into a ball mill to fully grind it for 12 hours, and then put it into a vacuum drying oven to dry for 10 hours after suction filtration and water washing to obtain a non-metallic catalyst composed of nitrogen and phosphorus as a porous carbon material.

[0039] Compared with the commercial platinum-carbon catalyst, the nitrogen-phosphorus co-doped porous carbon material non-metallic catalyst with a carbonization act...

Embodiment 3

[0041] Mix xylitol, polyaniline and sodium hypophosphite in a mass ratio of 1:1:1 as a carbonization precursor, add carbonization activator nickel chloride (1% of the total mass of carbonization precursor), and grind for twelve hours Afterwards, a carbonization treatment was carried out under nitrogen. Carbonize for 1 hour (carbonization temperature is 850 ℃, heating rate 2 ℃ / min), then soak in 1 M hydrochloric acid for 14 hours, then put it into a ball mill for full grinding for 12 hours, suction filter, wash with water, and put it into vacuum drying After oven drying for 10 hours, a non-metallic catalyst consisting of nitrogen and phosphorus porous carbon material is obtained.

[0042] Compared with commercial platinum-carbon catalysts, the half-potential shifted negatively by 20 mV when nitrogen-phosphorus co-doped porous carbon material non-metallic catalysts were added with 1% carbonization activator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com