Method and apparatus for a directly electrically heated flow-through chemical reactor

A chemical reaction and chemical technology, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, separation methods, etc., can solve problems such as poor chemical tolerance, uneven heat dispersion, and chemical substance operation , to achieve the effects of improving chemical resistance, eliminating dead volume, and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

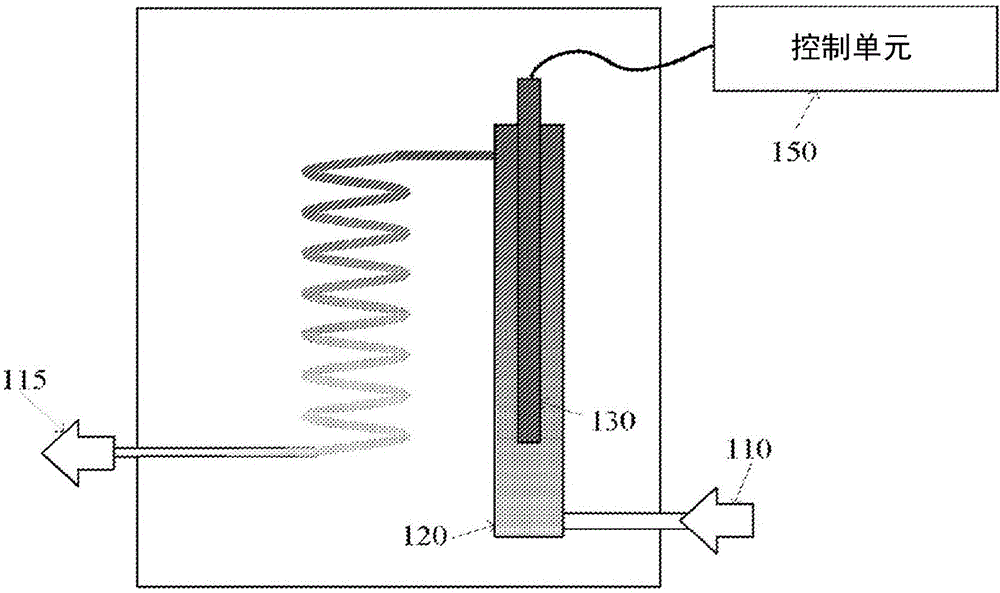

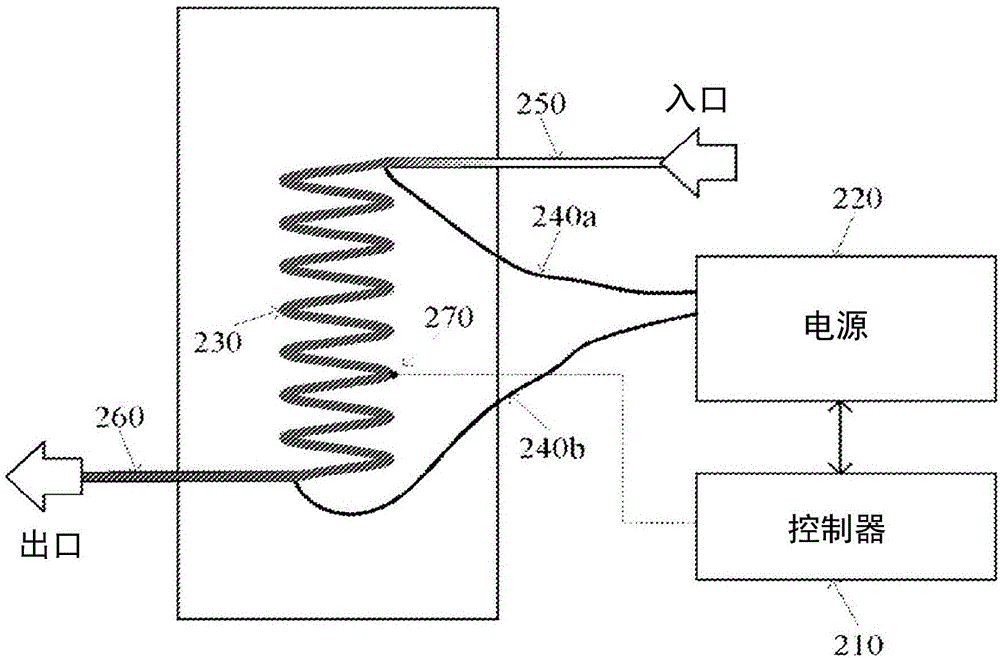

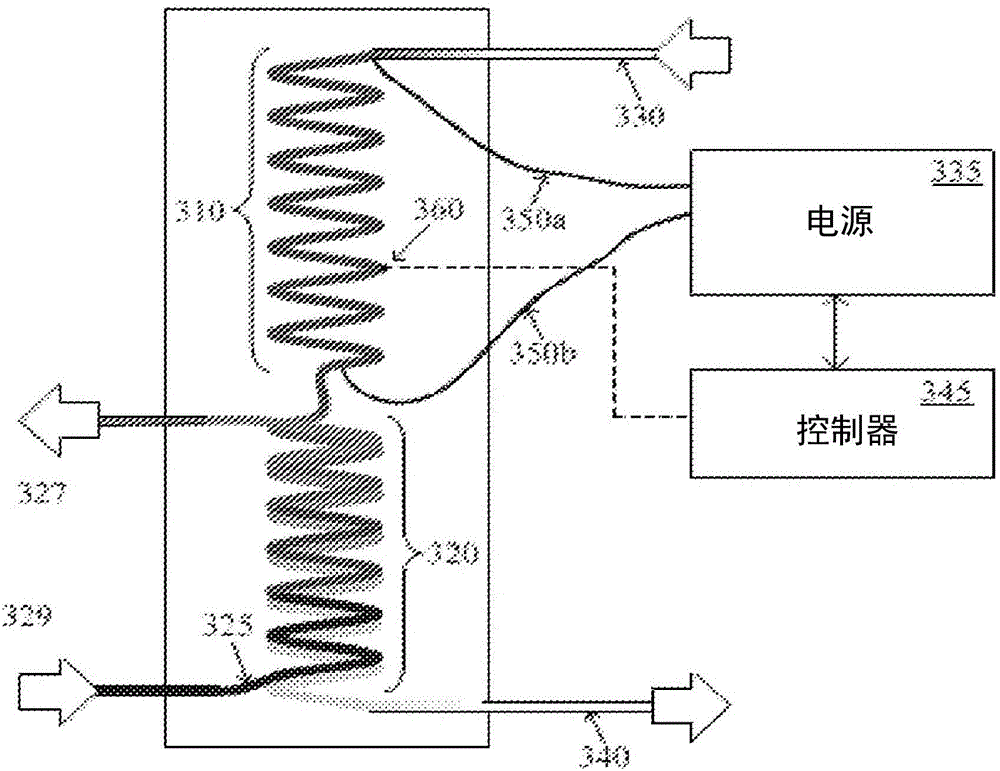

[0031] The invention generally involves the direct connection of an electrically conductive component, such as a metal pipe, to a power source. The conductive component is capable of holding the chemical mixture inside. The power supply applies power to the conductive component. The conductive component is heated by the applied power. The electrically conductive component has an interior region through which a chemical mixture can circulate.

[0032] When the chemical mixture is placed into the interior region of the conductive component and power is applied, heat generated in the conductive component is transferred to the chemical mixture, causing the chemical mixture to be heated. A portion of the conductive component can be cooled. The cooled portion of the conductive component is capable of cooling the chemical mixture flowing through the conductive component. In one embodiment, after the chemical mixture has been heated, the chemical mixture can be cooled.

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com