Method for manufacturing fruit and vegetable humidity-adjusting fresh-keeping film

A manufacturing method and technology of fresh-keeping film, applied in papermaking, textiles and papermaking, water-repellent addition, etc., can solve problems such as excessive chloride ion content, moisture permeability change, air pollution of regenerated cellulose, etc., achieve simple production operation, prevent Accelerates festering and maintains water retention and freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

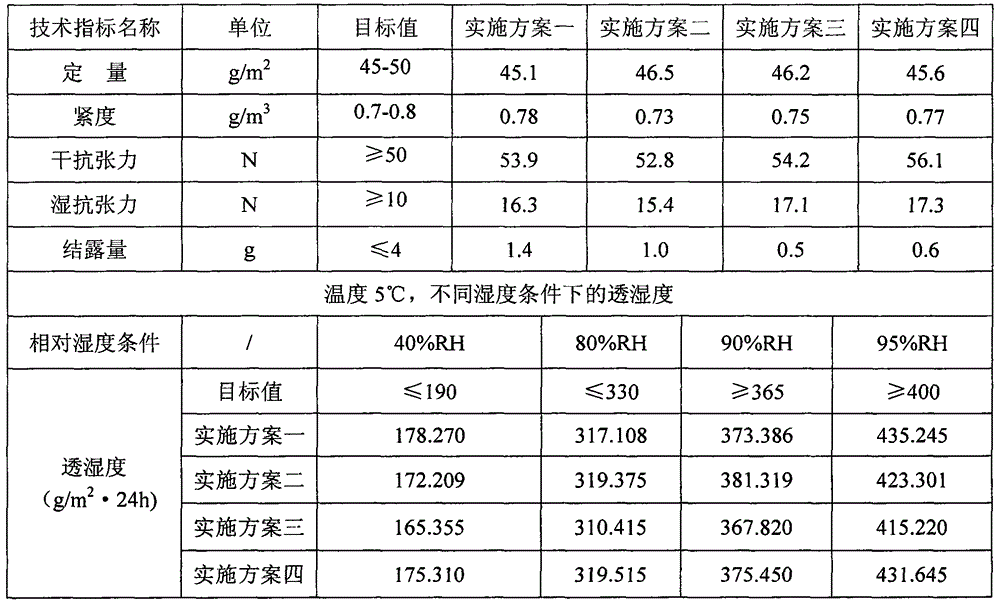

[0014] Embodiment one: base paper: 100% coniferous wood pulp, beating degree 50 ° SR, PAE 1.0%, polyacrylamide 0.5%; Applied coating: base paper adopts the mode of surface sizing to impregnate 7% sodium carboxymethyl cellulose and 0.3 % quinoline copper mixed glue. Dissolving method of sodium carboxymethylcellulose: Dissolve in water at 50-60°C for about 3 hours to form a uniform colloidal dispersion. Surface sizing method: Use a two-roller surface gluing machine for surface gluing, and the amount of glue dipping is 5-7g / m 2 ; Dry and calendered. The test results of the finished paper are shown in Table 1.

Embodiment 2

[0015] Embodiment two: base paper: 100% coniferous wood pulp, beating degree 35 ° SR, PAE 1.0%, cationic starch 1.5%; Applied coating: base paper adopts the mode of double-sided coating to coat 5% sodium carboxymethyl cellulose and 0.3% thiabendazole mixed glue. Dissolving method of sodium carboxymethylcellulose: Dissolve in water at 50-60°C for about 3 hours to form a uniform colloidal dispersion. Coating method: use bar coating, the total coating amount on both sides is 5-7g / m 2 ; Dry and calendered. The test results of the finished paper are shown in Table 1.

Embodiment 3

[0016] Embodiment 3: base paper: 100% softwood pulp, beating degree 35 ° SR, PAE 1.0%, polyacrylamide 0.5%; application layer: base paper is coated with a polymer mixture by double-sided coating, the polymer mixture The formula is: 5% gelatin solution, 1.5% glutaraldehyde cross-linking agent (to gelatin dry weight), 0.5% chitin. The dissolving method of gelatin solution: take a certain amount of gelatin solid and add water to make a concentration of 10% (mass fraction), soak at room temperature for 2 hours, heat it in a constant temperature water bath at about 70°C after it swells, and stir slowly, Until a uniform colloidal dispersion is obtained, then dilute to 5% glue; add glutaraldehyde solution to the prepared gelatin solution, the addition amount is 3% (to the amount of absolute dry gelatin), and then add a small amount of anti-mold and antibacterial agent, stir well and set aside. Coating method: use bar coating, the total coating amount on both sides is 5-7g / m 2 ; Dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com