A kind of conductive agent, its preparation method and lithium ion battery containing the conductive agent

A conductive agent, an unsubstituted technology, applied in the field of lithium-ion battery materials, can solve the problems of large market share, high price, and difficulty in dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

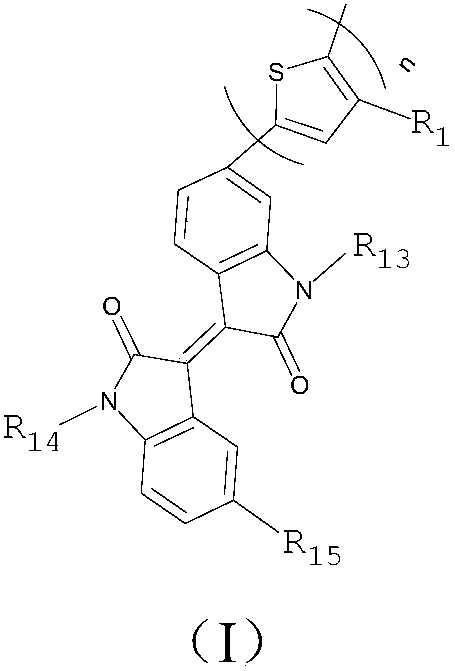

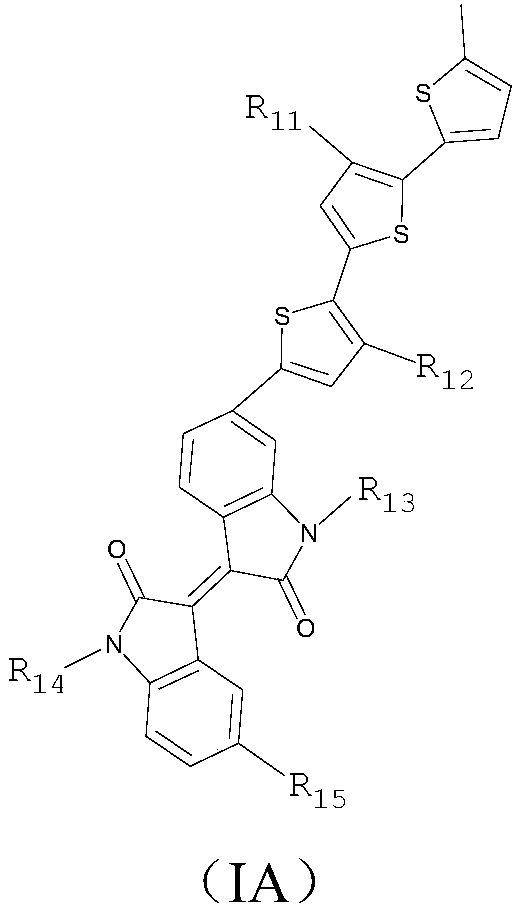

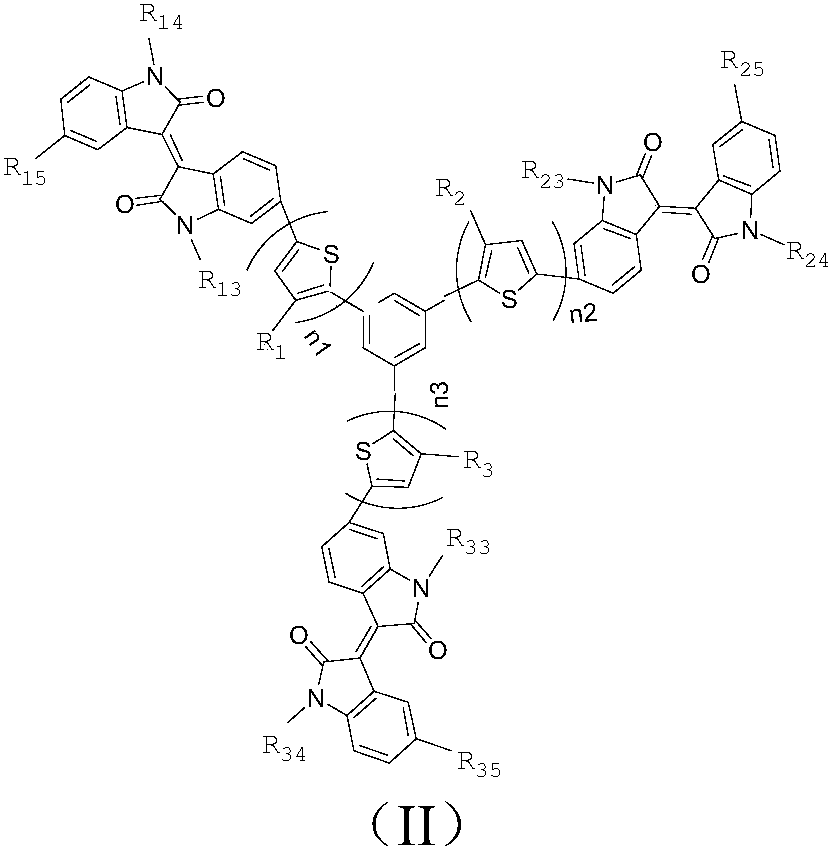

Image

Examples

preparation example Construction

[0082] In order to achieve the second objective of this application, the preparation method of the conductive agent shown in formula III includes at least the following steps:

[0083] Step 1): Preparation of compound 3

[0084] Compound 1 and compound 2 are subjected to a substitution reaction to obtain compound 3.

[0085] As an improvement of the preparation method of the conductive agent of the present application, the reaction temperature is 100°C to 120°C, the reaction time is 22 to 26 hours, and tris(dibenzylideneacetone)dipalladium is added as a catalyst during the reaction. Phenyl) phosphorus acts as a ligand. Compound 1: Compound 2: Tris (dibenzylideneacetone) dipalladium: tris (o-methylphenyl) phosphorus in a molar ratio of 1.55 to 1.75: 1.85 to 2.05: 0.035 to 0.055: 0.145 to 0.175. The reaction is carried out in an inert gas.

[0086]

[0087] Step 2): Preparation of compound 4

[0088] Compound 3 is subjected to substitution reaction with N-bromosuccinimide to obtain com...

Embodiment 1~3

[0107] The structural formulas of the conductive agents of Examples 1 to 3 are shown in Formula III, and the specific selection of substituents is shown in Table 1:

[0108]

[0109]

[0110] Table 1

[0111] Example

R 11 , R 21 , R 31

R 12 , R 22 , R 32

R 13 , R 23 , R 33

R 14 , R 24 , R 34

R 15 , R 25 , R 35

Example 1

Hexyl

Hexyl

2-ethylhexyl

2-ethylhexyl

-F

Example 2

Sinki

Sinki

-F

Example 3

Phenyl

Phenyl

Methoxy

Methoxy

-F

[0112] Specifically, the preparation method of the conductive agent shown in Example 1 is:

[0113] Step 1): Preparation of compound 3

[0114] The N-2-ethylhexyl-5-fluoro-6'-bromoisoindigo (4820mg, 8.2mmol), 3,4'-dihexyl-(2,2'-dithiophene)-5-trimethyl Stannane (4940mg, 9.8mmol), tris(dibenzylideneacetone) dipalladium (190mg, 0.2mmol) and tris(o-methylphenyl)phosphorus (250mg, 0.83mmol) were added to a 500mL dry round bottom flask. The flask was repeatedly evacuated and filled with argon. After the atmosphere in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com