Sodium-doped CIGS (copper indium gallium selenide) film based on composite substrate and preparation method thereof

A technology of copper indium gallium selenide and composite substrate, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc. The effect of good quality, easy implementation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

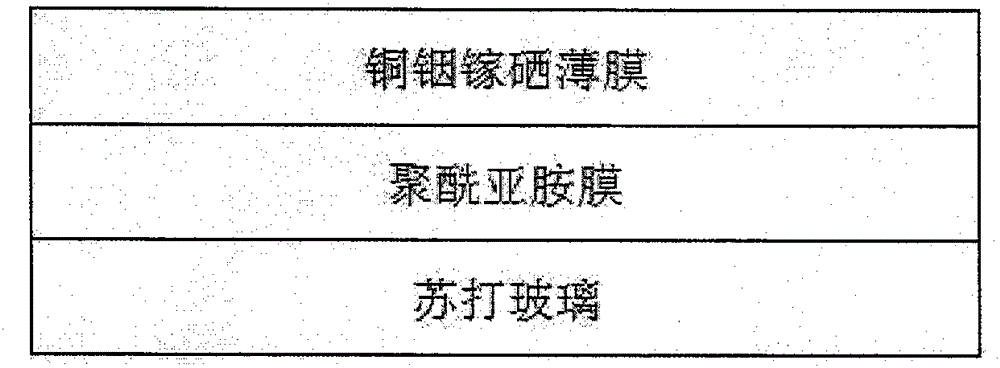

[0033] A copper indium gallium selenium thin film based on polyimide film-soda glass composite substrate, as shown in Figure 1, the chemical molecular formula is Culn 1-x Ga x Se2, where x is 0.25, and the conductivity type is p-type, the CuInGaSe thin film Culn 1-x Ga x Se 2 The film is deposited on the surface of the polyimide film-soda glass composite substrate with a thickness of 1.5 μm; the preparation method is to prepare the polyimide film-soda glass substrate by uniform glue and curing process, and the film is prepared by selenization furnace The system uses a co-evaporation one-step preparation process to prepare a copper indium gallium selenium thin film on a composite substrate, and the preparation steps are as follows:

[0034] (1) Cleaning of soda glass

[0035] 1) Put a 10cm×10cm soda glass into potassium dichromate-concentrated sulfuric acid solution, which is composed of 300 grams of potassium dichromate, 3 liters of concentrated sulfuric acid and 300 ml of...

Embodiment 2

[0048] A copper indium gallium selenium thin film based on polyimide film-soda glass composite substrate, as shown in Figure 1, the chemical molecular formula is Culn 1-x Ga x Se 2 , where x is 0.35, and the conductivity type is p-type; the CuInGaSe thin film CuIn 1-x Ga x Se 2 The film is deposited on the surface of the polyimide film-soda glass composite substrate with a thickness of 2 μm; the preparation method adopts the process of uniform glue and curing to prepare the polyimide film-soda glass substrate, and uses a selenization furnace film preparation system, The copper indium gallium selenium thin film on the composite substrate is prepared by the co-evaporation one-step preparation process, and the preparation steps are as follows:

[0049] (1) Cleaning of soda glass

[0050] 1) Put a 10cm×10cm soda glass into potassium dichromate-concentrated sulfuric acid solution, which is composed of 300 grams of potassium dichromate, 3 liters of concentrated sulfuric acid an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com