Diffusion-technology-based manufacture method for fast recovery diode chip having double buffering layers

A recovery diode and double buffer layer technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve fast recovery diode chips with large reverse recovery peak current, unfavorable manufacturing of high-voltage fast recovery diode chips, and parameter requirements. Advanced problems, to achieve the effect of shortening the width of the base area, low cost, and short recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

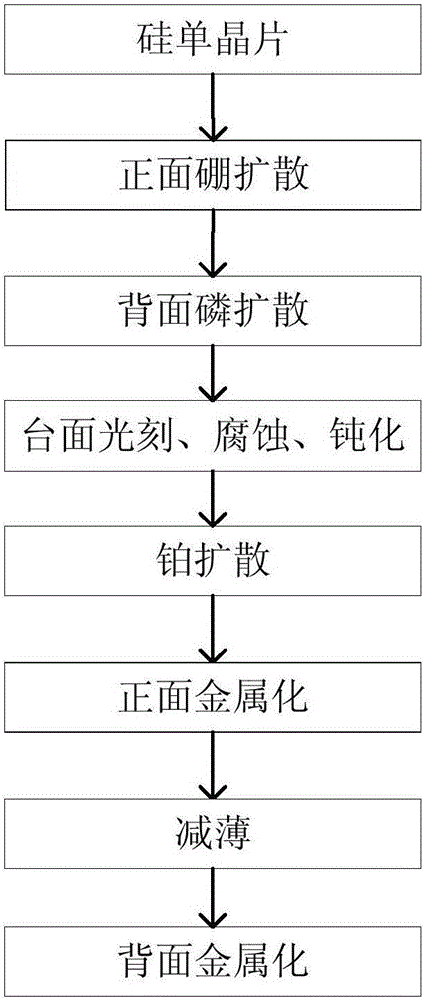

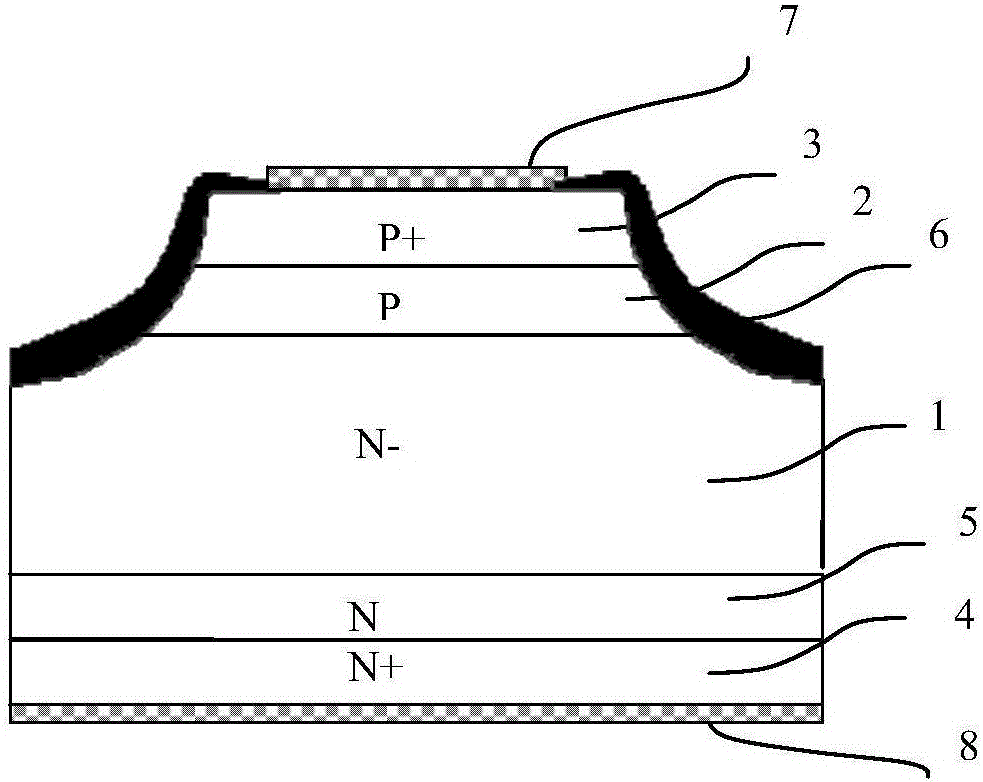

[0046] By adopting the manufacturing method of the invention, the anode and the cathode of the fast recovery diode chip are formed by diffusion, the process steps are simple, and the fast recovery diode chip with low cost, high withstand voltage, short recovery time and soft recovery characteristics can be manufactured. The specific implementation is as follows:

[0047] (1) Use N-type single-polished silicon single wafer as the base material, deposit oxide layer and silicon nitride layer on the non-polished surface of this N-type silicon single wafer, and then use boron-doped latex as the impurity source, at 1100 ~ Boron diffusion is performed on the polished surface of N-type silicon single wafer at 1250°C for 10-20 hours, and a diode anode is formed on the polished surface of N-type silicon single wafer, even if the N-type silicon single wafer forms an N-type silicon single wafer with a diode anode. wafer. The anode structure formed by diffusion is a P+P structure. The exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com