High-speed wire production method for tracking the quality status of individual strands and individual coils

A high-speed wire and production method technology, applied in the field of metallurgy, can solve the problems of low efficiency of manual intervention, weak control, cost waste, etc., and achieve the effect of realizing traceability, reducing various problems, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

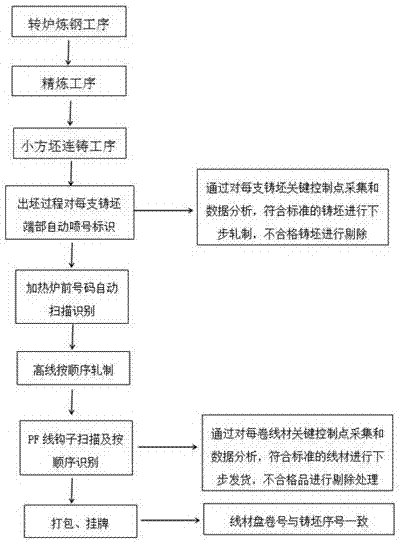

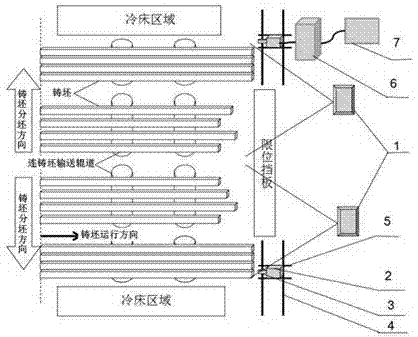

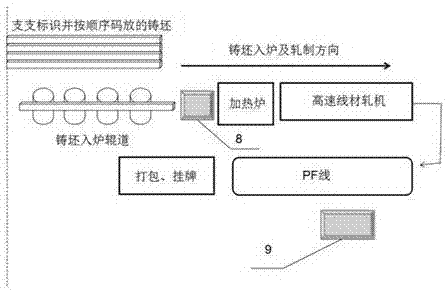

[0032] The main process flow of a wire rod production system is a 120-ton steelmaking converter, LF ladle refining furnace, eight-machine eight-strand billet continuous casting machine (to produce billets with a cross-section of 165mm×165mm), heating furnace, and high-speed wire rod rolling mill. The original process control method is to judge the casting slab with the furnace as the unit, and there are many problems. Applying the method provided by the present invention, two sets of continuous casting slab automatic spraying numbers are added to the billet discharge area of the continuous casting machine in the original process flow. The device is composed of electronic label sensor 1, numbering machine body 2, numbering head 3, traverse track 4, longitudinal track 5, control cabinet 6, server (computer control system) 7, and enters the furnace roller in the heating furnace An automatic scanning identification device 8 for billet number is added before the road, and an autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com