The method of demagnetization before narrow gap pulse fusion welding of oil drill collar

A narrow gap, oil drilling technology, applied in welding equipment, magnetic objects, arc welding equipment, etc., can solve problems such as poor practicability, achieve stable arc state, reduce residual magnetic field strength, and improve weld bead formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

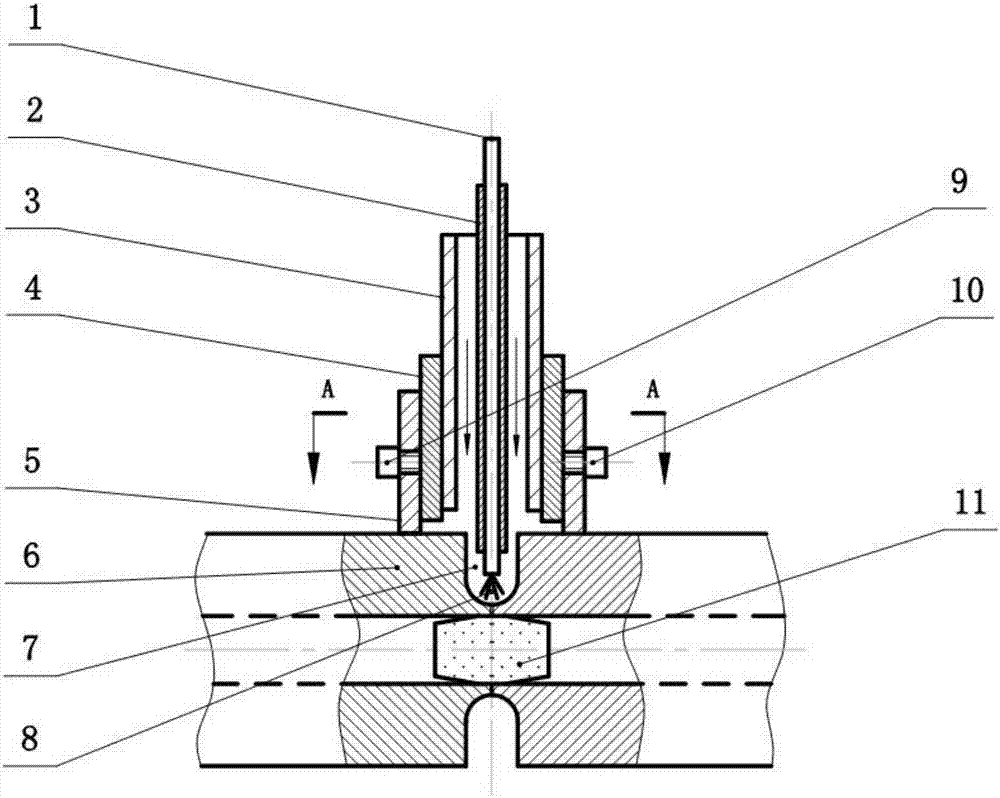

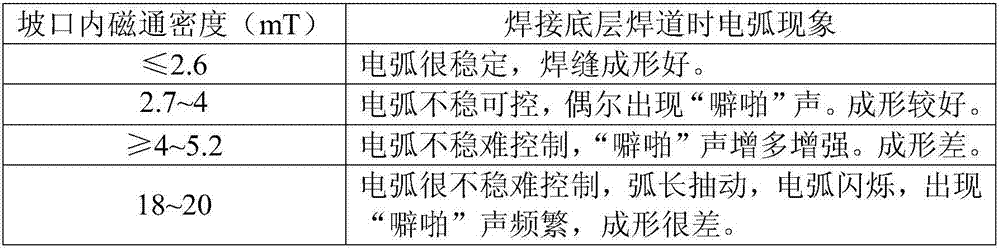

[0019] refer to Figure 1-2 . Aiming at the influence of the residual magnetic intensity in the narrow gap groove on the bottom arc, the magnetic deflection blow test of the arc is specially studied. Before welding, the CT3 Teslameter was used to detect the magnetic flux density in the groove, and then the arc was ignited to weld the bottom bead. It will be unstable, and this instability cannot be overcome by adjusting the welding specification parameter value, so the weldment groove must be demagnetized before welding.

[0020] Table 1 Influence of magnetic flux density in the narrow gap groove on the arc of the bottom weld bead

[0021]

[0022] The principle of magnetic shielding is used to demagnetize the narrow gap groove of oil drill collars to avoid arc magnetic deflection during bottom arc welding. Its characteristics include the following steps:

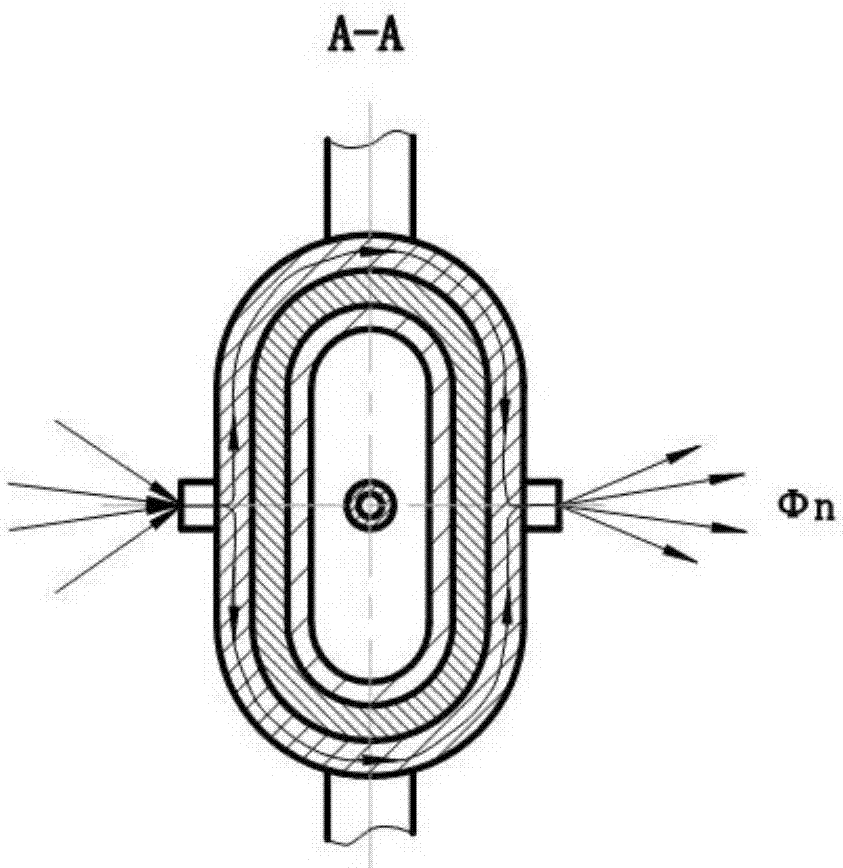

[0023] 1. In the gun body of the existing narrow-gap pulse melting polar gas shielded automatic welding torch, a mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com