Manufacturing method of chia-seed-based pressed oil and processing method of pressed cake meal

A processing method and technology of chia seeds, which are applied in the processing of pressed cakes and the preparation of pressed oil, to achieve the effects of low melting consumption, low production cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

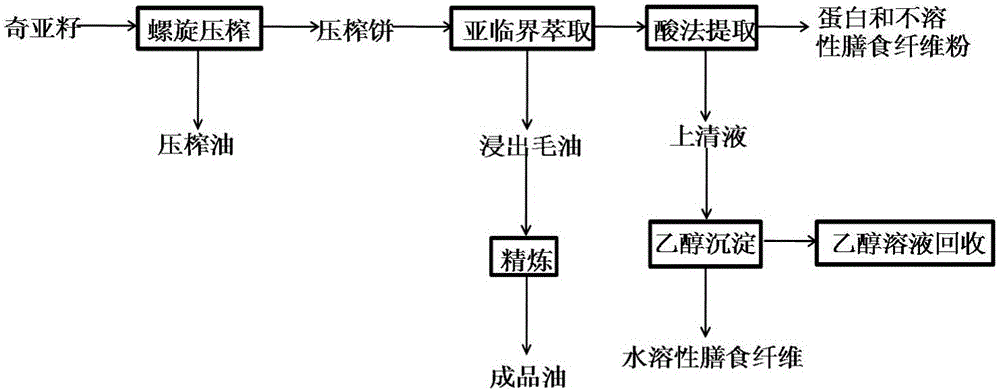

Method used

Image

Examples

Embodiment 1

[0034](1) 4 kg of chia seeds were screw pressed, and the obtained chia seeds pressed oil had a moisture content of 0.06%, an acid value of 0.54 mgKOH / g, a POV value of 1.43 mmol / kg, and a yield of 22.4%.

[0035] (2) Subcritical extraction is carried out on the cake after screw pressing, the extraction temperature is below 40° C., the extraction time is 40 minutes, and the extraction solvent is butane, and the residual oil of the obtained cake is less than 2%.

[0036] (3) Add water to the meal after subcritical extraction of chia seeds, the ratio of solid to liquid is 1:12, adjust the pH to acidic, heat at 50°C and centrifuge, add distilled water again to the insoluble matter, and then centrifuge, and centrifuge twice The supernatants were pooled. The insoluble matter is dried and pulverized to obtain protein and insoluble dietary fiber powder, wherein the protein content is 40.7%, and the insoluble dietary fiber is 53.4%. The supernatant is alcohol-precipitated water-solubl...

Embodiment 2

[0038] A processing method of chia seeds, comprising the following steps:

[0039] Step 1. The chia seeds are squeezed by screw pressing technology to obtain pressed oil and pressed cake, and natural antioxidants are added to the pressed oil; wherein, the natural antioxidants account for 0.04% of the quality of the pressed oil, and the natural antioxidants are rosemary extract;

[0040] Step 2. Using subcritical extraction to extract the residual oil in the pressed cake, the subcritical extraction conditions are as follows: the temperature is 20°C, and the time is 60 minutes to obtain crude oil and extracted cake;

[0041] Step 3. Refining the subcritically extracted crude oil. The refining steps are: crude oil, heating, mixing, neutralization, washing, heating, drying, decolorization, filtration, fine filtration, decolorization of oil, heat exchange, gas separation, heat exchange , deodorization, heat exchange, cooling, fine filtration, deodorization of oil. The specific re...

Embodiment 3

[0044] A processing method of chia seeds, comprising the following steps:

[0045] Step 1. The chia seeds are squeezed by screw pressing technology to obtain pressed oil and pressed cake, and natural antioxidants are added to the pressed oil; wherein, the natural antioxidants account for 0.04% of the quality of the pressed oil, and the natural antioxidants are rosemary extract;

[0046] Step 2, using subcritical extraction to extract the residual oil in the pressed cake, the subcritical extraction conditions are: the temperature is 40°C, and the time is 30 minutes to obtain crude oil and extracted cake;

[0047] Step 3. Refining the subcritically extracted crude oil. The refining steps are: crude oil, heating, mixing, neutralization, washing, heating, drying, decolorization, filtration, fine filtration, decolorization of oil, heat exchange, gas separation, heat exchange , deodorization, heat exchange, cooling, fine filtration, deodorization of oil. The specific refining cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com