Soybean milk and dry-process preparation method thereof

A soymilk and dry process technology, which is applied to the field of low energy consumption soymilk and its dry process preparation, can solve the problems of high temperature and long processing time, and achieve the effects of improving extraction rate, simple production operation and reducing denaturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of soybean milk, soybean 65 Kg, white sugar 60 Kg, purified water 870.75 Kg, soybean milk stabilizer 3 Kg, acesulfame potassium 0.1 Kg, sucralose 0.05 Kg, 0.20 Kg of sodium erythorbate, 0.3 Kg of sodium tripolyphosphate , soy milk essence 0.2 Kg, condensed milk essence 0.1 Kg, baking soda 0.3 Kg, pH: 7.0.

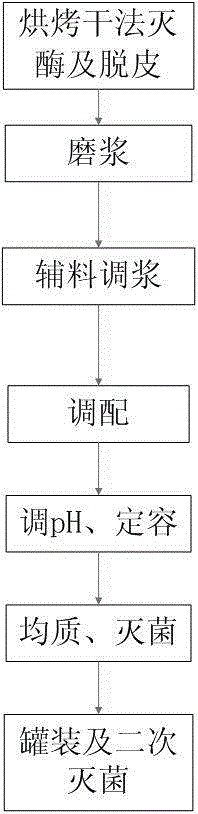

[0041] refer to figure 1 , a dry preparation method of soybean milk, comprising the following steps:

[0042] 1) Enzyme elimination and peeling by drying method: Soybeans are screened to remove impurities, put into the oven, and baked at 100°C for 15 minutes. When the soybeans reach four maturity, the soybeans are taken out, cooled and peeled;

[0043] 2) Refining: Coarsely crush the peeled soybeans in step 1 to irregular particles with a particle size of 2.5mm, and then add 2.31 times the weight of soybeans (150Kg) of water to grind the irregular soybeans into soybean milk ;

[0044] 3) Blending of auxiliary materials: mix the weighed raw materials and sug...

Embodiment 2

[0051] A kind of soybean milk, soybean 68 Kg, white sugar 65 Kg, purified water 860Kg, soybean milk stabilizer 4Kg, acesulfame potassium 0.15 Kg, sucralose 0.03Kg, sodium erythorbate 0.25Kg, sodium tripolyphosphate 0.3 Kg, soybean milk Essence 0.15 Kg, condensed milk essence 0.12 Kg, baking soda 0.2 Kg, pH: 7.20.

[0052] refer to figure 1 , a dry preparation method of soybean milk, comprising the following steps:

[0053] 1) Enzyme elimination and peeling by drying method: Soybeans are screened to remove impurities, put into the oven, and baked at 105°C for 18 minutes. When the soybeans reach five maturity, the soybeans are taken out, cooled and peeled;

[0054] 2) Refining: Coarsely crush the peeled soybeans in step 1 to irregular particles with a particle size of 3.0mm, and then add 2.5 times the weight of soybeans (170Kg) of water to grind the irregular soybeans into soybean milk ;

[0055] 3) Blending of auxiliary materials: mix the weighed raw materials and sugar into...

Embodiment 3

[0062] A kind of soybean milk, soybean 60 Kg, white sugar 58 Kg, purified water 850Kg, soybean milk stabilizer 2.5Kg, other auxiliary materials are the same as embodiment 1, pH: 7.20.

[0063] refer to figure 1 , a dry preparation method of soybean milk, comprising the following steps:

[0064] 1) Enzyme elimination and peeling by drying method: Soybeans are screened to remove impurities, put into the oven, and baked at 110°C for 12 minutes. When the soybeans reach four maturity, the soybeans are taken out, cooled and peeled;

[0065] 2) Refining: Coarsely pulverize the peeled soybeans in step 1 to irregular particles with a particle size of 2.0mm, and then add 2.0 times the weight of soybeans (130Kg) of water to grind the irregular soybeans into soybean milk ;

[0066] 3) Blending of auxiliary materials: mix the weighed raw materials and sugar into a stirring tank with a water temperature of 80°C for 8 minutes, and the water consumption for blending of auxiliary materials i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com