ifbr-uasb-iceas industrial wastewater treatment process

A 1.IFBR-UASB-ICEAS, industrial wastewater technology, applied in the direction of return water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of unsatisfactory treatment effect, unfavorable microbial absolute anaerobic environment, treatment high cost problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

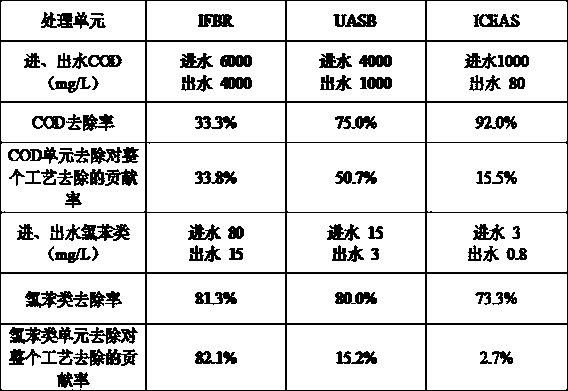

[0040] The comprehensive wastewater produced by a chemical company needs to be treated. The influent concentration before treatment is COD≤6000mg / L, pH 6.5~8.5, SS≤300mg / L, NH 3 -N≤100mg / L, TP≤2.5mg / L, characteristic pollutant concentration chlorobenzenes≤80mg / L. The effluent is required to meet the secondary standard of "Jiangsu Provincial Chemical Industry Discharge Standards for Major Water Pollutants" (DB32 / 939-2006). The effluent indicators require COD≤120mg / L, pH 6.5~8.5, SS≤150mg / L, NH 3 -N≤25mg / L, TP≤1.0mg / L, characteristic pollutant concentration chlorobenzenes≤1.0 mg / L.

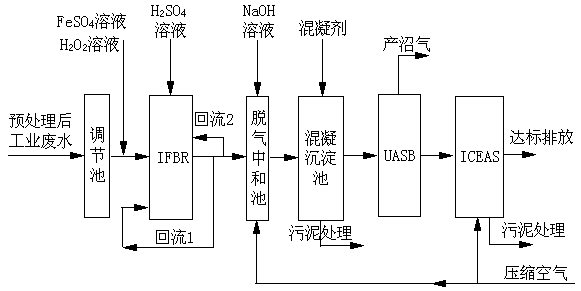

[0041] Attached figure 1 The combined process in the combined use of improved Fenton fluidized bed (IFBR), upflow anaerobic sludge bed (UASB) and ICEAS reactor to treat chemical wastewater; including regulating tank, improved Fenton fluidized bed, The degassing neutralization tank, coagulation sedimentation tank, upflow anaerobic sludge bed, and ICEAS reactor are connected in sequence through wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com