Method for preparing multi-tunnel cobaltosic oxide flower-like microspheres by solvothermal method

A technology of tricobalt tetroxide flower and solvothermal method, which is applied in the direction of cobalt oxide/cobalt hydroxide, nanotechnology, etc., to achieve good reproducibility, convenient mass production, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cobalt tetroxide (Co 3 o 4 ) The preparation steps of the micron flower-shaped ball are as follows:

[0027] a. Put 2mmol cobalt nitrate into 35ml EG, add copper nitrate according to the ratio of cobalt nitrate: copper nitrate 2:1, and keep stirring until the solution is uniform;

[0028] b. Then add 2ml of ammonia water (25-28wt%) and stir until uniform;

[0029] c. Transfer to a polytetrafluoroethylene-lined reaction kettle, keep the temperature at 180°C for 12 hours, then cool naturally to obtain a hydrothermal product;

[0030] d. Centrifuge the hydrothermal product obtained above, and wash with absolute ethanol and deionized water for 3 times respectively;

[0031] e. Dry the centrifuged product in a vacuum oven at 60°C for 12 hours to obtain the precursor;

[0032] f. Put the precursor in the tube furnace with N 2 Calcined at 500°C for 3h to obtain the final product.

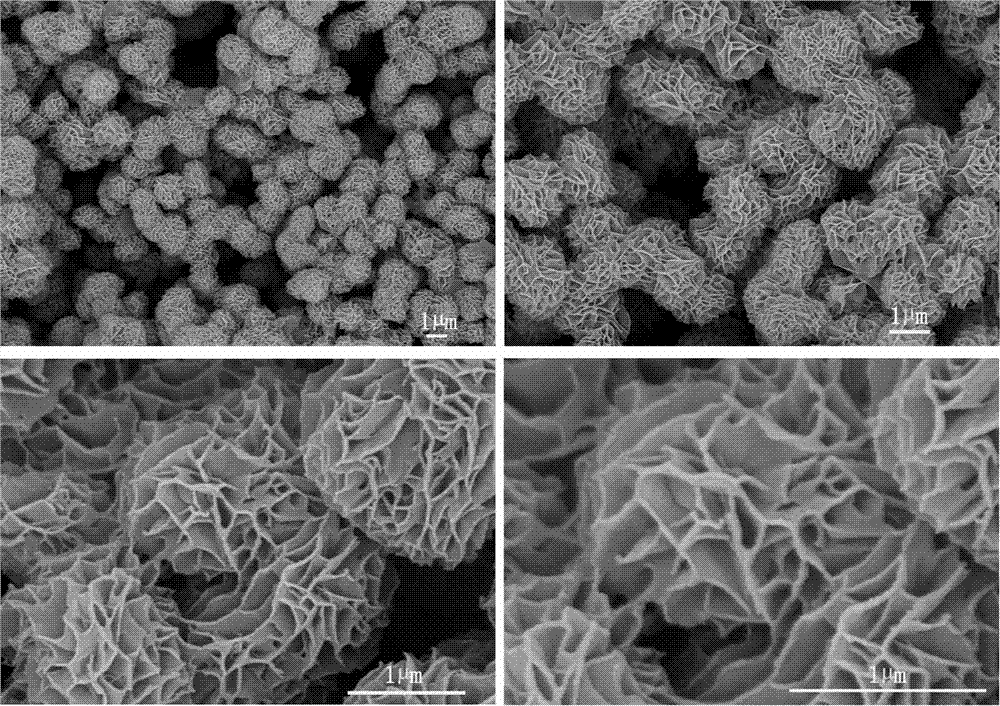

[0033]

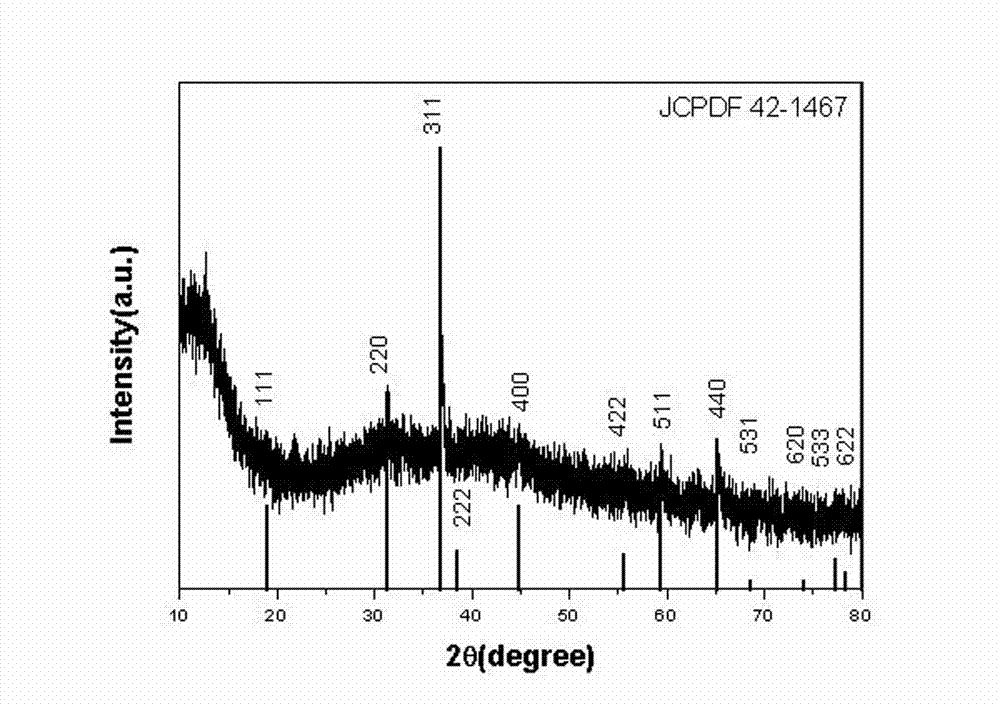

[0034] co 3 o 4 The XRD of the micron flower-shaped ball product is shown in ...

Embodiment 2

[0039] Cobalt tetroxide (Co 3 o 4 ) The preparation steps of the micron flower-shaped ball are as follows:

[0040] a. Put 2mmol cobalt nitrate into 35ml EG, add copper nitrate according to the ratio of cobalt nitrate: copper nitrate 2:1, and keep stirring until the solution is uniform;

[0041] b. Then add 1ml of ammonia water (25-28wt%) and stir until uniform;

[0042] c. Transfer to a polytetrafluoroethylene-lined reaction kettle, keep the temperature at 180°C for 12 hours, and then cool naturally to obtain a hydrothermal product;

[0043] d. Centrifuge the hydrothermal product obtained above, and wash with absolute ethanol and deionized water for 3 times respectively;

[0044] e. Dry the centrifuged product in a vacuum oven at 60°C for 12 hours to obtain the precursor;

[0045] f. Put the precursor in the tube furnace with N 2 Protected and calcined at 500°C for 3h to obtain the final product.

Embodiment 3

[0047] Cobalt tetroxide (Co 3 o 4 ) The preparation steps of the micron flower-shaped ball are as follows:

[0048]a. Put 2mmol cobalt nitrate into 35ml EG, add copper nitrate according to the ratio of cobalt nitrate: copper nitrate 2:1, and keep stirring until the solution is uniform;

[0049] b. Then add 2ml of ammonia water (25-28wt%) and stir until uniform;

[0050] c. Transfer to a polytetrafluoroethylene-lined reaction kettle, keep the temperature at 160°C for 12 hours, and then cool naturally to obtain a hydrothermal product;

[0051] d. Centrifuge the hydrothermal product obtained above, and wash with absolute ethanol and deionized water for 3 times respectively;

[0052] e. Dry the centrifuged product in a vacuum oven at 60°C for 12 hours to obtain the precursor;

[0053] f. Put the precursor in the tube furnace with N 2 Protected and calcined at 500°C for 3h to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com