Processing method of explosive wastewater

A technology of explosive waste water and treatment method, which is applied in water/sewage treatment, special compound water treatment, light water/sewage treatment, etc. It can solve the problems of large waste water discharge, non-biodegradable and difficult biodegradable, etc., and achieves convenient maintenance , low cost, stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of Copper-Cerium Modified Titanium Dioxide Catalyst

[0037] 1. Preparation of ceramsite carrier

[0038] Take 2.0kg of sludge, 1.0kg of clay, 1.0kg of kaolin, 1.0kg of fly ash, and 0.2kg of water glass, and mix them well to form The columnar ceramsite blank is heated in a high-temperature furnace at a temperature of 10°C to 500°C, pre-fired at a constant temperature for 30 minutes, then raised to 1100°C at a rate of 5°C / min, sintered for 20 minutes, and cooled to below 300°C at a rate of 10°C / min. Take out and cool naturally, the appearance of the porous ceramsite carrier is brick red short columnar solid particles. After inspection, there is no leaching of toxic substances, and it has good apparent density and porosity, so it can be used as a catalyst carrier material.

[0039] The surface of the prepared ceramsite ceramics is rough, loose and porous, the particle porosity is as high as 55%, and the specific surface area is 380m 2 / g; stable chemical p...

Embodiment 2

[0046] 1. Measure 1000ml of explosive waste water, adjust the pH value to 4 with 10% dilute sulfuric acid, add potassium persulfate with a molar concentration of 0.2, the amount added is 5% of the waste water, and mix well;

[0047] 2. Put a 259nm ultraviolet lamp in the water, add the copper-cerium-modified titanium dioxide catalyst prepared in Example 1 with 5% waste water, aerate with 30mL / s gas output, react for 6 hours, and the reaction ends. Detect COD, TN, SS, TNT, RDX, DNT content of wastewater;

[0048] The test results are as follows:

[0049] Test items

Embodiment 3

[0051] 1. Measure 1000ml of explosive waste water, adjust the pH value to 2 with 10% dilute sulfuric acid, add potassium persulfate with a molar concentration of 0.15, the amount added is 10% of the waste water, and mix well;

[0052] 2. Put a 259nm ultraviolet lamp in the water, add a copper-cerium-modified titanium dioxide catalyst with 20% waste water, aerate with 40ml of air output, react for 12 hours, and the reaction ends. Detect the COD, TN, SS, TNT, RDX, HMX content of wastewater; the test results are as follows:

[0053] Test items

Removal rate (%)

COD (mg / l) (chemical oxygen demand)

1660

25

98.5

TNT (mg / l) (TNT)

7

not detected

~100

DNT(mg / l)(dinitrotoluene)

6

not detected

~100

RDX(mg / l)(RDX)

2.85

not detected

~100

SS (Suspended Solids)

23

4

82.6

TN (total nitrogen)

128

2.7

97.9

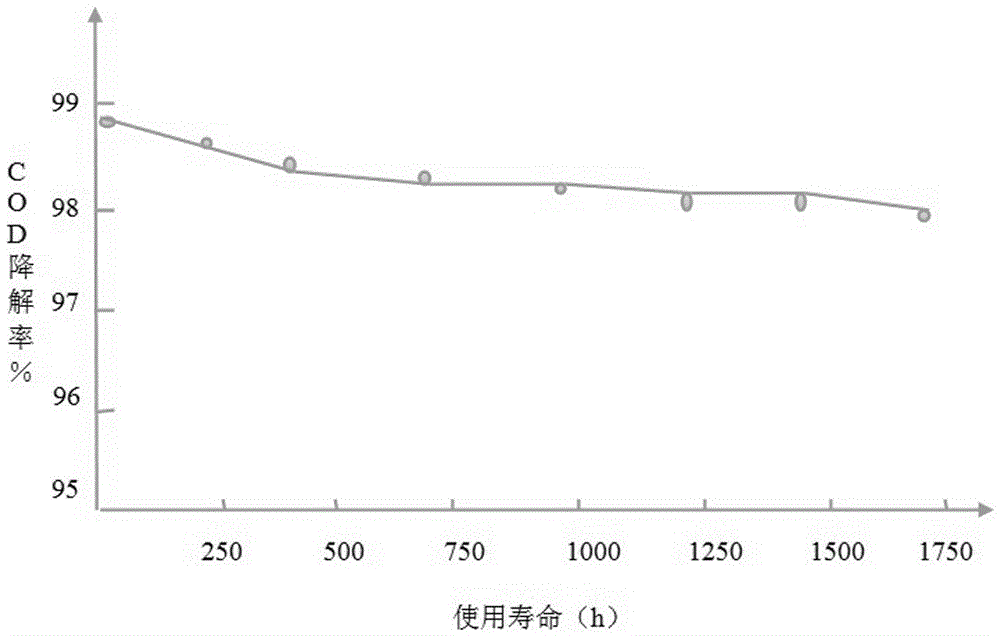

[0054] 3. After the catalyst is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com