Vanadium slag comprehensive treatment method and application thereof

A comprehensive treatment, vanadium slag technology, applied in the direction of improving process efficiency, etc., to achieve the effect of improved recovery rate, simple operation and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

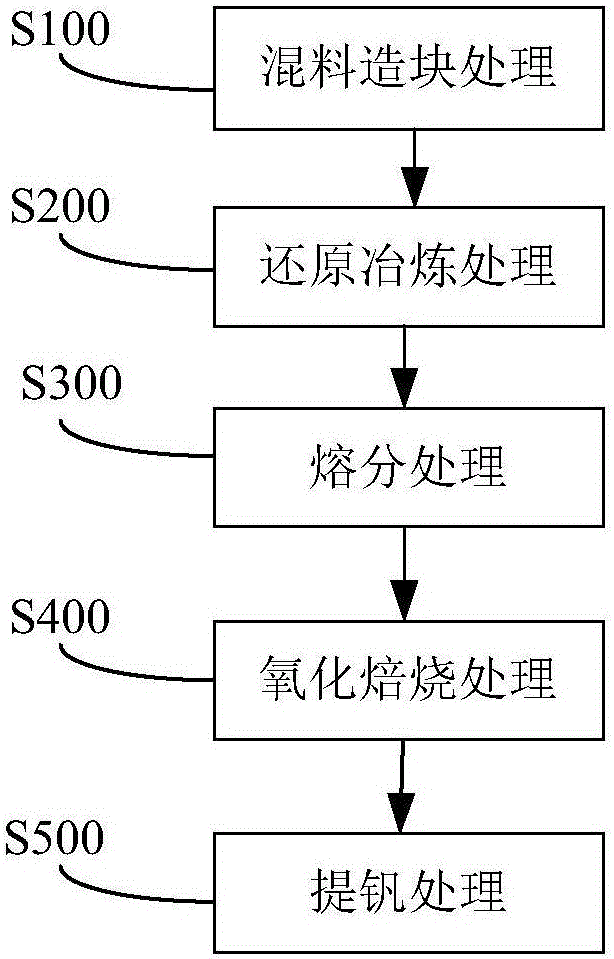

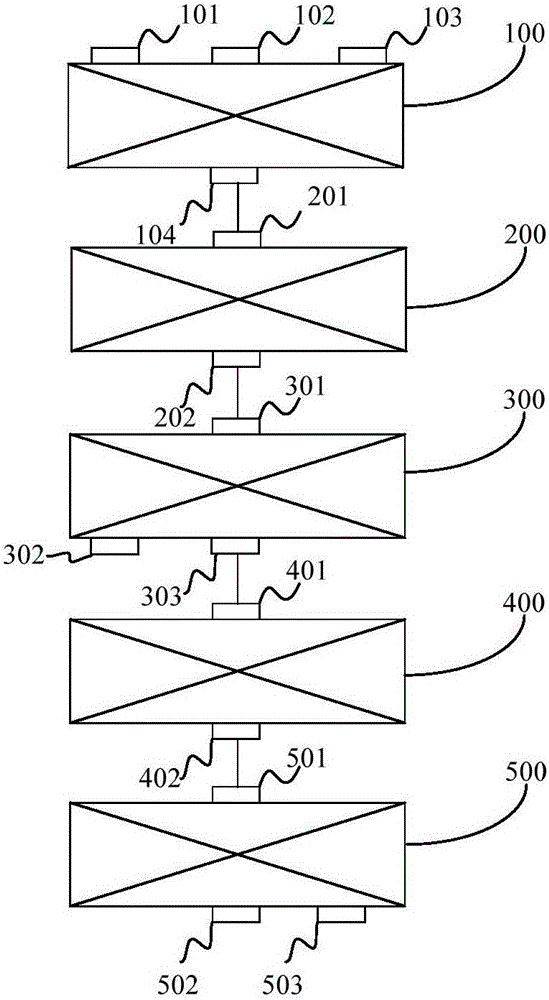

[0074] Taking vanadium slag from a vanadium-extracting steelmaking plant in China as raw material, the method of the present invention is used to carry out comprehensive treatment of vanadium slag. The schematic flow chart of the method is as follows figure 1 As shown, the structural diagram of the comprehensive treatment system for vanadium slag is as follows figure 2 As shown, wherein, the vanadium slag contains 35% of total iron and 16% of vanadium pentoxide, and the specific treatment method is as follows:

[0075] (1) Utilize the mixing block making device to vanadium slag and sodium carbonate (analytically pure, content 99.5%) and reduced coal (fixed carbon content 78%), vanadium slag by weight: sodium carbonate: reduced coal=100:15 : 6 carry out batching mixing, obtain mixed material agglomerate.

[0076](2) Put the mixed material agglomerate into the rotary hearth furnace for direct reduction smelting, the smelting temperature is 1000° C., and the smelting time is 45...

Embodiment 2

[0081] Taking vanadium slag from a vanadium-extracting steelmaking plant in China as raw material, the method of the present invention is used to carry out comprehensive treatment of vanadium slag. The schematic flow chart of the method is as follows figure 1 As shown, the structural diagram of the comprehensive treatment system for vanadium slag is as follows figure 2 As shown, wherein, the vanadium slag contains 42% of total iron and 20% of vanadium pentoxide, and the specific treatment method is as follows:

[0082] (1) Utilize the mixing and agglomerating device to vanadium slag and sodium sulfate (analytically pure, content 99.5%) and semi-coke (fixed carbon content 82%), by weight ratio vanadium slag: sodium sulfate: semi-coke=100:25 : 9 carries out batching mixing, obtains mixed material agglomerate.

[0083] (2) Put the mixed material agglomerates into a rotary hearth furnace for direct reduction smelting at a smelting temperature of 1200° C. and a smelting time of 1...

Embodiment 3

[0088] Taking vanadium slag from a vanadium-extracting steelmaking plant in China as raw material, the method of the present invention is used to carry out comprehensive treatment of vanadium slag. The schematic flow chart of the method is as follows figure 1 As shown, the structural diagram of the comprehensive treatment system for vanadium slag is as follows figure 2 As shown, wherein, the vanadium slag contains 25% of total iron and 14% of vanadium pentoxide, and the specific treatment method is as follows:

[0089] (1) Utilize the mixing and agglomerating device to vanadium slag and sodium chloride (analytically pure, content 99.5%) and coke (fixed carbon content 86%), by weight ratio vanadium slag: sodium chloride: coke=100:20 :12 carries out batching mixing, obtains mixed material agglomerate.

[0090] (2) Put the mixed material agglomerate into the tunnel kiln for direct reduction smelting, the smelting temperature is 1150° C., and the smelting time is 1.5 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com